- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

AOBL

-

Model Number:

-

MP series

-

Place of Origin:

-

China

-

Horsepower:

-

380V

-

Structure:

-

seal

-

Cable Length:

-

Type

-

Outlet Size:

-

Type

-

Power:

-

Type

-

Product name:

-

Mini water circulation acid transfer chemical magnetic drive pump

-

Caliber:

-

40-1.5"/ 50-2"/ 75-3"

-

Pole number:

-

2-2P

-

Feature:

-

High Flow

-

Material:

-

GFRPP, PVDF

-

Power(HP):

-

0.05-0.5HP /01-1HP /02-2HP /03-3HP/05-5HP /07-7HP /10-10HP

-

Certificate:

-

ISO9001

-

Name:

-

Chemical magnetic drive pump

Quick Details

-

Application:

-

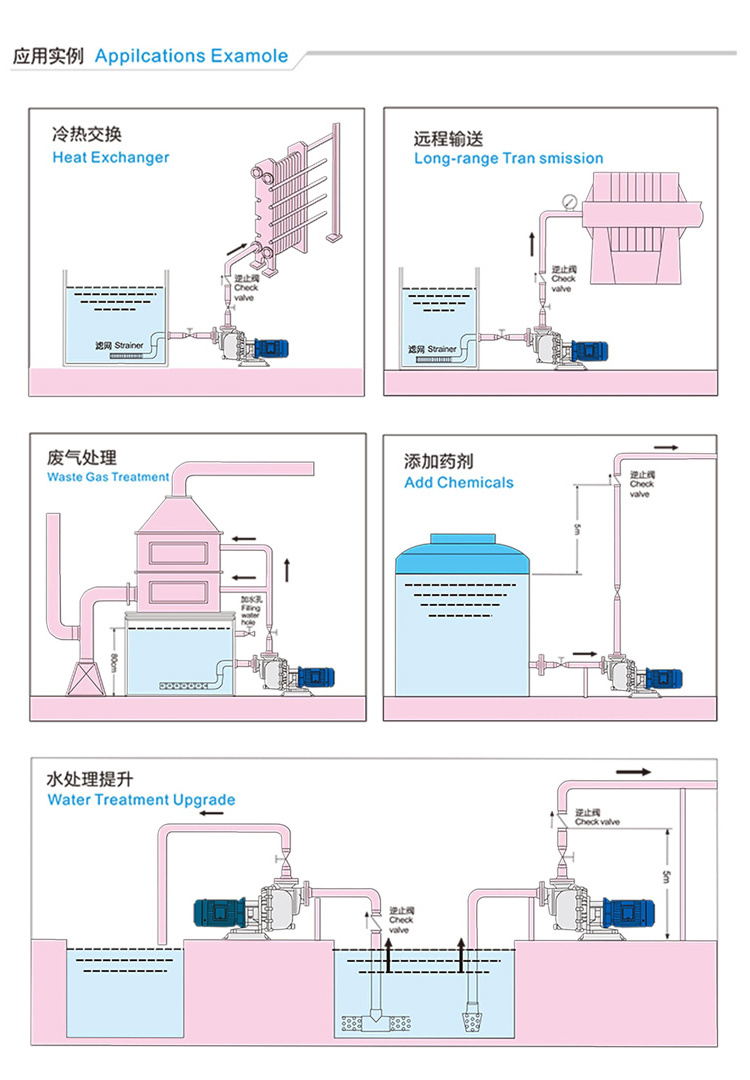

Wastewater Transport and Flood Control, wastewater treatment

-

Pressure:

-

High pressure

-

Voltage:

-

220V/380V, 220V/380V

-

Warranty:

-

1 year

-

Brand Name:

-

AOBL

-

Model Number:

-

MP series

-

Place of Origin:

-

China

-

Horsepower:

-

380V

-

Structure:

-

seal

-

Cable Length:

-

Type

-

Outlet Size:

-

Type

-

Power:

-

Type

-

Product name:

-

Mini water circulation acid transfer chemical magnetic drive pump

-

Caliber:

-

40-1.5"/ 50-2"/ 75-3"

-

Pole number:

-

2-2P

-

Feature:

-

High Flow

-

Material:

-

GFRPP, PVDF

-

Power(HP):

-

0.05-0.5HP /01-1HP /02-2HP /03-3HP/05-5HP /07-7HP /10-10HP

-

Certificate:

-

ISO9001

-

Name:

-

Chemical magnetic drive pump

Products Description

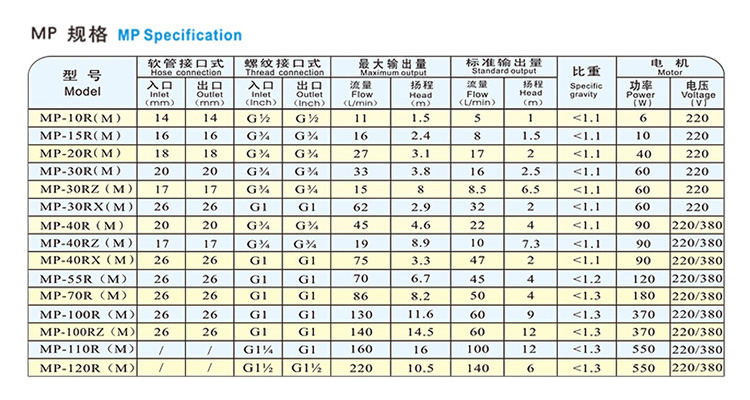

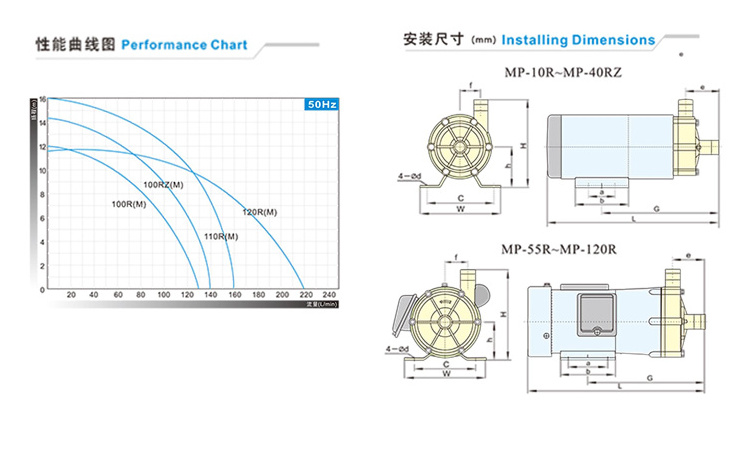

MP series magnetic pump adopts no shaft seal design, the pump body is completely sealed, no leakage, will not cause the pump body corrosion and environmental pollution, is the ideal corrosive liquid transport system.The MP series has a maximum flow rate from 11 l/min to 220 l/min with hose connection and threaded connection options.The neck is made of glass fiber reinforced polypropylene and high alumina ceramic, and most of the chemical liquid can be safely transported. Modular pump body assembly.Make maintenance extremely easy.

Material GFAPP, applicable temperature: below 80℃, PVDF applicable temperature: below 120℃.

Material GFAPP, applicable temperature: below 80℃, PVDF applicable temperature: below 120℃.

1. Different chemical solutions mixed together will cause reaction and even heat to damage the pump. Don't pump different chemical solutions with the same pump.

2. Chemicals may cause serious injury. Keep away from dangerous area.

3. Before operating, please check the discharge and suction line and valvesrst. Make sure valves are all in correct position, then start. During operation, check discharge usually.

4. Incorrect operation, for example, valves closed, incompatible material and dry running may cause dangerous. Especially dry running, it will cause heat as well as vapor, even some chemical decomposes hydrogen and explode.

5. Start the pump and check the discharge from the outlet. If it is too low, unplug the pump immediately, and check the pipeline if there is any block..

6. The pump can be equipped with explosive-proof and pressure-proof motor.

2. Chemicals may cause serious injury. Keep away from dangerous area.

3. Before operating, please check the discharge and suction line and valvesrst. Make sure valves are all in correct position, then start. During operation, check discharge usually.

4. Incorrect operation, for example, valves closed, incompatible material and dry running may cause dangerous. Especially dry running, it will cause heat as well as vapor, even some chemical decomposes hydrogen and explode.

5. Start the pump and check the discharge from the outlet. If it is too low, unplug the pump immediately, and check the pipeline if there is any block..

6. The pump can be equipped with explosive-proof and pressure-proof motor.

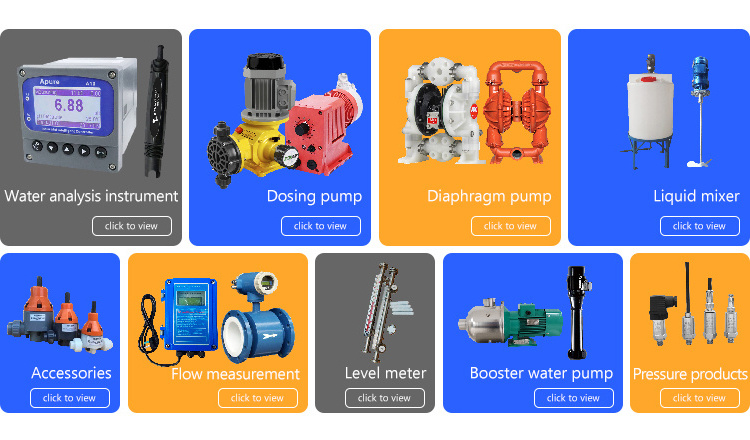

Recommend Products

Hot Searches