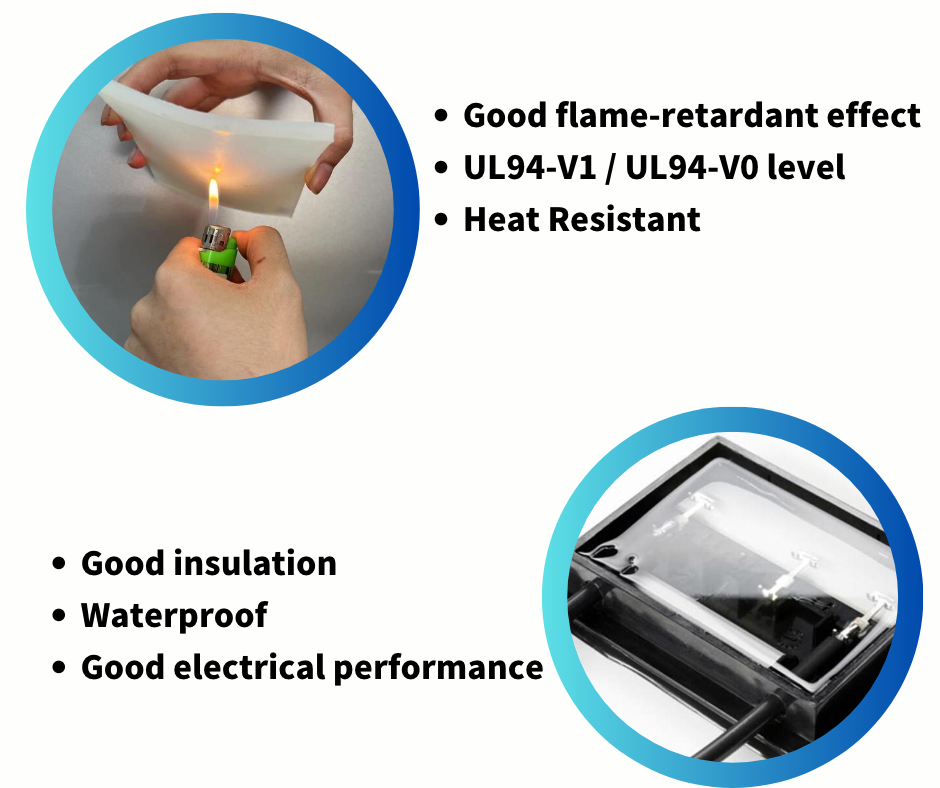

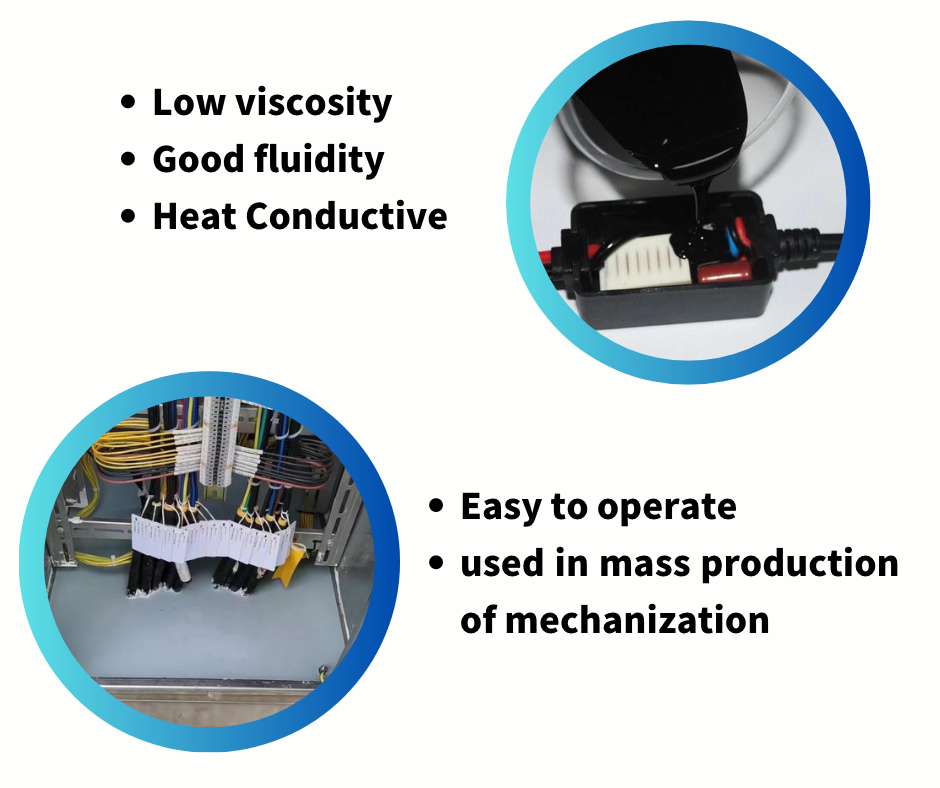

Electronic potting silicone is a two-component room temperature vulcanization silicone material, with flame retardant and thermal conductivity, can be cured at room temperature or heating. It is divided into condensation type electronic potting adhesive and additive electronic potting silicone.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Raw Material Silicone Rubber

-

VISCOSITY (Mpa.s):

-

6000-8000

-

Mixing ratio:

-

1:1/10:1

-

Application:

-

Liquid Silicone

-

Hardness:

-

15 Shore

-

Shelf life:

-

12 Months

-

Sample service:

-

Sample Test

-

Color:

-

Adjustable

Quick Details

-

Place of Origin:

-

Huizhou

-

Brand Name:

-

Jiajing Hong Silicone

-

Model Number:

-

9405

-

Product name:

-

Raw Material Silicone Rubber

-

VISCOSITY (Mpa.s):

-

6000-8000

-

Mixing ratio:

-

1:1/10:1

-

Application:

-

Liquid Silicone

-

Hardness:

-

15 Shore

-

Shelf life:

-

12 Months

-

Sample service:

-

Sample Test

-

Color:

-

Adjustable

Products Description

Electronic potting silicone

Product Usage

* Suitable for insulation, waterproofing, fixing and flame retardant of electronic accessories and DC modules.

* Application to PC (Polycarbonate), PP, ABS, PVC and other materials and metal surfaces.

* High power electronic components, power boxes, etc.

* Potting protection for module power supplies and circuit boards with high heat dissipation and temperature resistance requirements.

* Application to PC (Polycarbonate), PP, ABS, PVC and other materials and metal surfaces.

* High power electronic components, power boxes, etc.

* Potting protection for module power supplies and circuit boards with high heat dissipation and temperature resistance requirements.

Product Paramenters

|

Product Model

|

|

H9065

|

H9055

|

H9045

|

H9035

|

|

|

Components

|

|

A B

|

A B

|

A B

|

A B

|

|

|

Appearance

|

|

Dark gray White

|

Dark gray White

|

Dark gray White

|

Dark gray White

|

|

|

Before vulcanization

|

Dynamic viscosity (mPas)

|

5000±2000

|

5000±2000

|

3500±2000

|

5000±2000

|

|

|

|

A B two components mixing volume ratio

|

1:1

|

1:1

|

1:1

|

1:1

|

|

|

Operating Performance

|

Operation time(min/25℃

|

60-120

|

60-120

|

60-120

|

60-120

|

|

|

|

Vulcanization time(H,25℃)

|

8

|

8

|

8

|

8

|

|

|

|

Vulcanization time (min/80℃)

|

30

|

30

|

30

|

30

|

|

|

|

Hardness (Shore Aº)

|

65±3

|

55±3

|

45±3

|

35±3

|

|

|

|

Line rise coefficient [M/(m.K)

|

≤2.2×104

|

≤2.2×104

|

≤2.2×104

|

≤2.2×104

|

|

|

After vulcanization

|

Thermal conductivity [W/(M.k)

|

≥0.8

|

≥0.8

|

≥0.8

|

≥0.8

|

|

|

|

Dielectric insulation (KV/mm)

|

≥25

|

≥25

|

≥25

|

≥25

|

|

|

|

Dielectric constant (1.2MHZ)

|

3.0-3.3

|

3.0-3.3

|

3.0-3.3

|

3.0-3.3

|

|

|

|

Volume resistivity(Ω.CM)

|

≥1.0×1016

|

≥1.0×1016

|

≥1.0×1016

|

≥1.0×1016

|

|

|

|

Flame retardancy

|

UL94-V1

|

UL94-V1

|

UL94-V1

|

UL94-V1

|

|

Product packaging

Hot Searches