- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Processing:

-

AAC Block Production Line

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

100kw more

-

Dimension(L*W*H):

-

128000*30000*8000mm

-

Weight (KG):

-

980000 kg

-

Land:

-

Depends on capacity

-

Installation:

-

Engineer Guidance

-

Raw material:

-

concrete / flyash / sand / lime /cement / gypsum

-

Product Name:

-

AAC Block Production Line

-

Keywords:

-

AAC Block Production Line

-

Advantage:

-

lightweight, Cost saving

-

Capacity:

-

50000cbm-300,000cbm

-

Products:

-

AAC blocks, ALC Panels

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, AAC block production line

-

Brick Raw Material:

-

Sand or fly ash, gypsum, aluminium powder, etc

-

Production Capacity (Pieces/8 hours):

-

50,000cbm-300,000cbm per year

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Processing:

-

AAC Block Production Line

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

100kw more

-

Dimension(L*W*H):

-

128000*30000*8000mm

-

Weight (KG):

-

980000 kg

-

Land:

-

Depends on capacity

-

Installation:

-

Engineer Guidance

-

Raw material:

-

concrete / flyash / sand / lime /cement / gypsum

-

Product Name:

-

AAC Block Production Line

-

Keywords:

-

AAC Block Production Line

-

Advantage:

-

lightweight, Cost saving

-

Capacity:

-

50000cbm-300,000cbm

-

Products:

-

AAC blocks, ALC Panels

-

After-sales Service Provided:

-

Field installation, commissioning and training

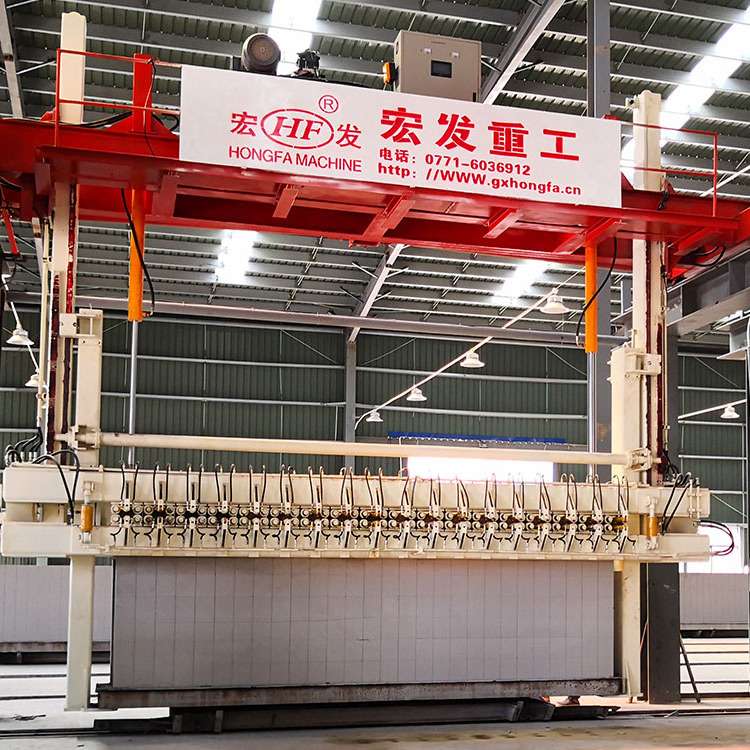

AAC Block Price List ALC Panel AAC Plant Manufacturer for Light Block AAC Block Production Line in Philippines

AAC Block Price List ALC Panel AAC Plant Manufacturer for Light Block AAC Block Production Line in Philippines

Hongfa Machinery since 1990

A leader developer& Manufacturer of Construction Material Machinery.

Guangxi production base: 9 machinery factories

Updated to state-owned enterprise.

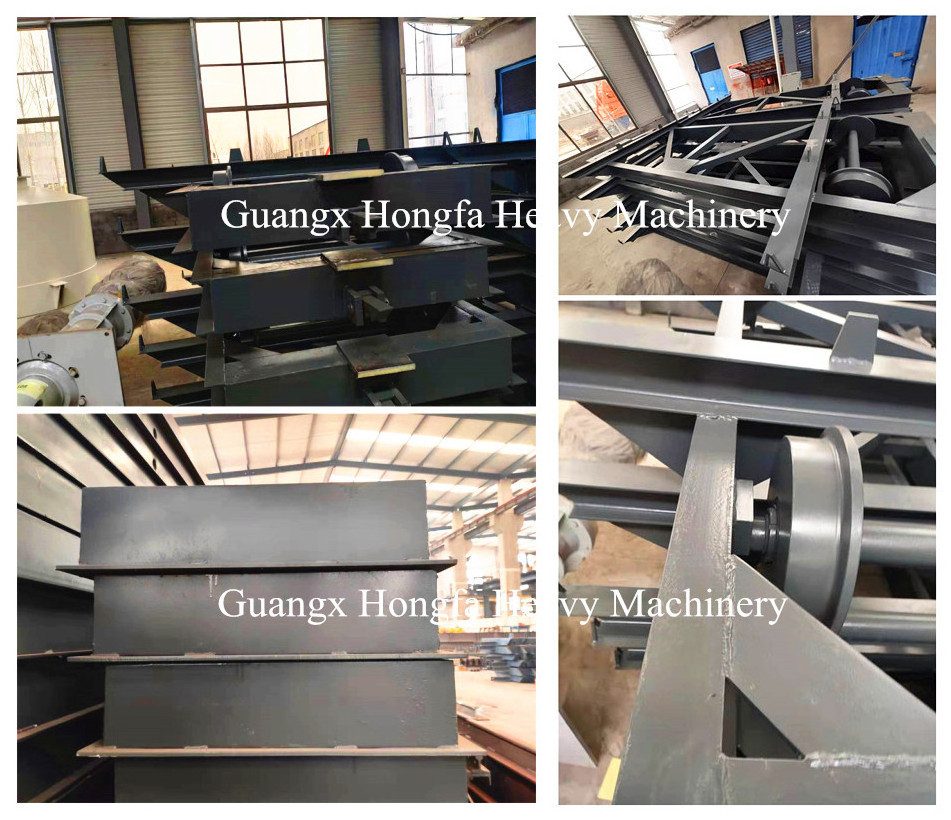

Raw material

To make our AAC block production line reliable and durable, HONGFA FACTORY purchases steel from famous steel manufacturers in

China. We only use steel plates that have not been rolled. A few underwater plasma cutting machines were purchased to guarantee

the high precision of our autoclaved aerated concrete production machines.

Hongfa service for AAC Block Price List ALC Panel AAC Plant Manufacturer for Light Block AAC Block Production Line

Hongfa Process Technology Research Center

The experimental center provides whole life service of Autoclaved aerated concrete project,

including raw material analysis, formula design, production guidance (On site& Remote), final sample performance test and expertise necessary training.

Hongfa Automation Technology Research Center

The automation research center provides customers with all-round comprehensive services, including training related to the electrical control and operation of AAC plant, intelligent technology research and development, upgrading and application testing.

After-sales service and training

a) Provide training and consulting services for

customers throughout the project life cycle, including but not limited to equipment operation,

safety instruction, equipment maintenance and process FAQs.

Contact with us for more details of AAC Block Price List ALC Panel AAC Plant Manufacturer for Light Block AAC Block Production Line

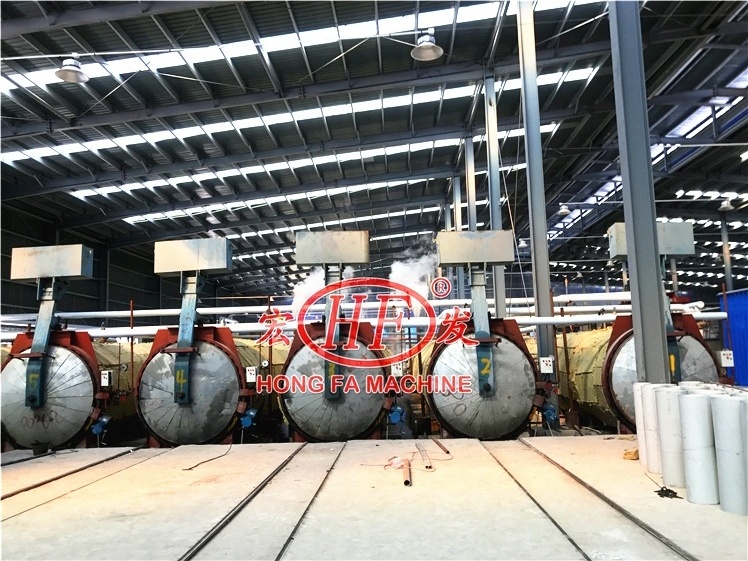

It has the advantages from the process:

1. It can realize the mixed grinding to prepare the cementitious material and effectively improve the pouring stability; the flowtube type pouring stirring can shorten the stirring time and greatly

improve the uniformity of stirring.

2. Raw material processing can realize the hydrothermal ball milling process and improve the

stability of fly ash and mortar.

3. Integrated layout technology, which arranges the batching, pouring, pre-cultivation, cutting, bottom removal, marshalling and other processes in the same workshop.

Uses hydraulic lifting and conveying equipment to separate the walking guide from the main

body of the workshop and reduce the height of the workshop. Layout, avoiding dead corners in

the building, shortening the return path of waste water and waste slurry, reducing the moving

space of operators and improving work efficiency.

AAC Block Price List ALC Panel AAC Plant Manufacturer for Light Block AAC Block Production Line in Philippines is running in our south of factory, welcome to visit us.

AAC Block Price List ALC Panel AAC Plant Manufacturer for Light Block AAC Block Production Line in Philippines

AAC Block Price List ALC Panel AAC Plant Manufacturer for Light Block AAC Block Production Line in Philippines

Hongfa AAC Block Price List ALC Panel AAC Plant Manufacturer for Light Block AAC Block Production Line in Philippines running in our south of factory , welcome to visit us!

AAC Block Price List ALC Panel AAC Plant Manufacturer for Light Block AAC Block Production Line in Philippines

Main process flow of AAC Block Price List ALC Panel AAC Plant Manufacturer for Light Block AAC Block Production Line in Philippines

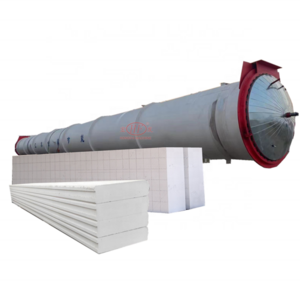

1.Raw material preparation for AAC plant AAC block production line :

A, Milling sand ( fly ash no need mill) and to make slurry

B, Lime: crushing - milling ( or to buy lime power directly)

C, Gypsum:to mill with sand or lime or input with fly ash then to make slurry directly.

2. Dry and wet Ball mill for lime and sand of AAC block production line

3.Slurry batching of AAC block production line

4. Pouring of AAC Block Price List ALC Panels AAC Plant Manufacturing plant AAC Block Machine Manufacturer Line AAC Block Production Line

Main parts of AAC Block Price List ALC Panel AAC Plant Manufacturer for Light Block AAC Block Production Line in Philippines

Hongfa AAC block production line workshop

Shipment of Lightweight Sand Fly Ash ALC Panels AAC Block Production Line AAC Plant Manufacturing plant AAC Block Machine Munufacturer

Hongfa AAC Block Price List ALC Panels AAC Plant Manufacturing plant AAC Block Machine Manufacturer Line AAC Block Production Line

Application of AAC BLOCKS

Autoclaved Aerated Concrete Block are widely used as external wall panel (exterior wall panel), internal wall panel (interior wall panel), partition wall panel, flooring, roofing, fence, cladding, curtain wall and facade etc.

Autoclaved Aerated Concrete AAC Block are widely used in different kinds of buildings, such as public facilities, industrial constructions, steel structure building, warehouse, workshop, stores, hospitals, hotels, apartments, villas, schools, supermarkets etc.

AAC/ALC light weight interior/exterior AAC block production line