- Product Details

- {{item.text}}

Quick Details

-

feature:

-

low noise, removable

-

technical service:

-

24 hours service

-

moisture required:

-

10-30%

-

input dia:

-

less than 50mm

-

output dia:

-

3-5mm

-

After-sales Service Provided:

-

Engineers available to servic machinery overseas, Field maintenance and repair service

-

Usage:

-

Chip.shaving.sawdust

-

Final product:

-

Size Adjustable

-

Weight:

-

800KG

Quick Details

-

Place of Origin:

-

Henan, China

-

Motor Type:

-

AC

-

Raw material:

-

tree branches, stalk, etc

-

feature:

-

low noise, removable

-

technical service:

-

24 hours service

-

moisture required:

-

10-30%

-

input dia:

-

less than 50mm

-

output dia:

-

3-5mm

-

After-sales Service Provided:

-

Engineers available to servic machinery overseas, Field maintenance and repair service

-

Usage:

-

Chip.shaving.sawdust

-

Final product:

-

Size Adjustable

-

Weight:

-

800KG

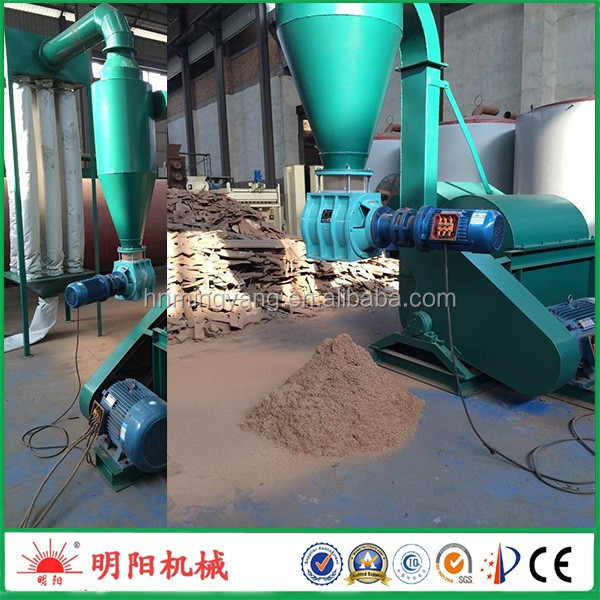

Hammer Mill Crusher Machine Design For Corn Nut Shell Rice Husk Tree Branch

1.Product Description of biomass hammer mill manufacturers

This series of biomass hammer mill have advantage of compact structure, Strong and durable, Safe and reliable, easy operation, lower noise and vibration, high efficiency and low energy consumption, etc. With double discharge to connect material and convenience to use, the spare part of the machine completely adopt quality material, outsourcing parts adopting domestic optimal product, the whole machine’s quality is reliable, long-lived.

2.Raw materials of the biomass hammer mill manufacturers

Biomass hammer mill is a new-style and widely used machine, which widely used in all kinds of shavings ,crop stalk, straw, hay, corn , soya, bagasse, sawdust, cotton firewood, bamboo powder, clover, peanuts shells, cotton seed fur, etc.

Morevere, the size of output can be changed according to customers' requirements

3.Features of the biomass hammer mill manufacturers

1.The

biomass hammer mill

shell is welded by steel plate,the site in the crush room, which connects to the materials andall use the wearable and commutative parts and double wear plate.

2.Coarse and fine power can both be achieved by adjusting the gaps between hammer and the screen by changing the location of the pin rod.

3.The motor and rotor are installed in the same heavy-duty base,using coupling direct drive,the rotor are checked by dynamic balance,and can work forward and reverse,the hammers are arranged symmetrically.

4.Teachnical datas of the biomass hammer mill manufacturers

Our company has different output biomass hammer mill as follows. The customers can select one machine accordinf their capacity.

However, if these bomass hammer mill can not satisfy you needs, we can offer other machines as your special requeirements.

|

Model |

Capacity(kg/h) |

Power |

packing size |

Final size |

Weight |

|

FJ-40 |

200-300 |

7.5kw |

1.3x0.6x1.2m |

3-5mm |

285kg |

| FJ-50 | 400-500 | 15KW |

1.6x1.4x1.8m |

3-5mm | 475kgs |

|

FJ-60 |

500-600 |

18.5kw |

1.6x1.4x1.8m |

3-5mm |

600kg |

|

FJ-70 |

600-800 |

22kw |

1.6x1.4x1.8m |

3-5mm |

770kg |

5.Working principle of the biomass hammer mill manufacturers

This biomass hammer mill is mainly component of casing, rotor, hammers and bars. The case is divided into two parts: up and down, which is connected by welding the cut steel; other parts are connected by screws. The one inside of case is high manganese steel lining board, which is easy to change when wore out. There are several hammers in the spindle, which make up of rotor together with turntable and wear hammer shaft. It works through motor and V-belt to drive spindle and rotor rotating, so that centrifugal force producing by the hammer rotating spread out. Then when the big material was put into crushing chamber, it was crush by the high speed hammer. Afer those process, the standard material was screen out by down bar and non-standard one was left on the crushing chamber and crush again. In order to avoid clogging, humidity of crushed material should below 10%-15%.

6.Final products of the biomass hammer mill manufacturers

1.The particle size of this biomass hammer mill is small, and can be crushed directly without drying by sun or dryer machines.

2. The whole wquipment only use a motor driving.

3.It has simple structure and compact decoration.

4. Cheap cost, stable quality, less energy consumption, and high efficiency.

The final wood chips could be used for bwiquette or pellet making.

For one set we packed in standard container.For more sets machines, we pack them in the standard container.