- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2420*700*1010mm

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

KOEN

-

Weight:

-

1600

-

Dimension(L*W*H):

-

2420*700*1010mm

Products Description

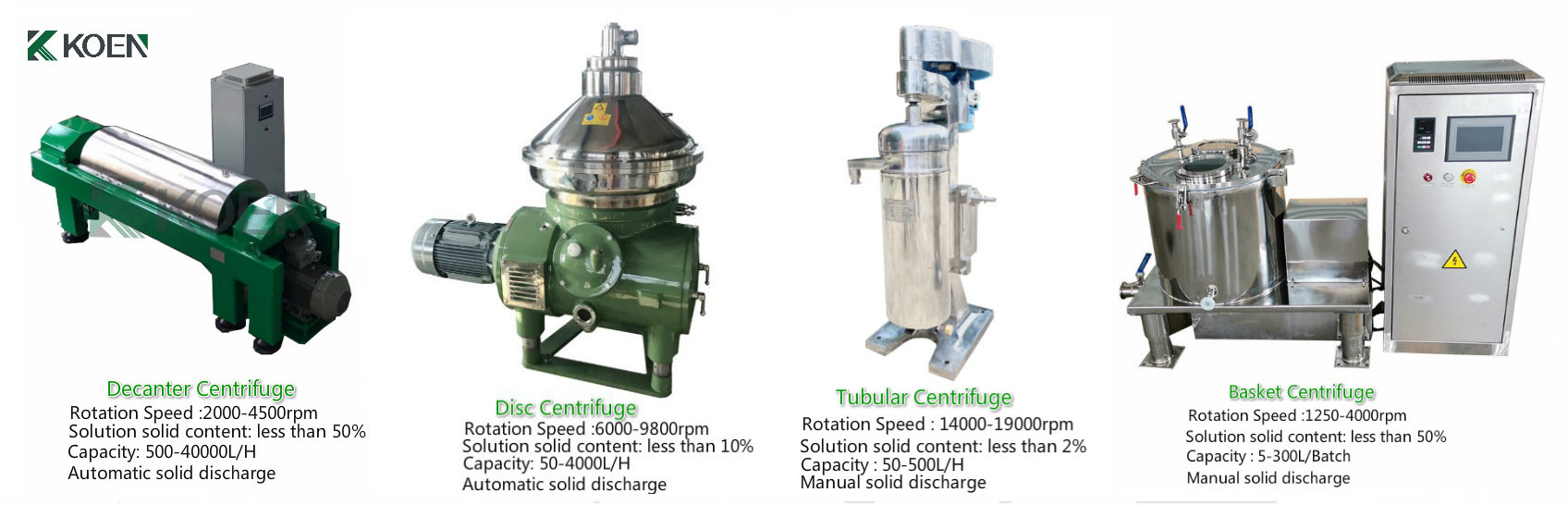

Industrial Price Decanter Centrifuge

LW Sedimentation Centrifuge is a horizontal, continuously working and continuously spiral discharging sedimentation centrifuge. It is used in a variety or industries for separating all kinds of solid liquid suspension, defecating liquid phase with graded rains, and dehydrating sludge.

2 phase Decanter Centrifuge:

After entering into the high-speed turning drum, the solid-phase particles in the mixed liquid run and settle on the drum

wall under the action of greatest centrifugal force; the light liquid settles at the innermost place of the drum under minimum centrifugal force; same as the drum's turning direction, a screw feeder also turns at a high speed, and a constant speed difference is generated by the differential mechanism, then the liquid will be discharged by the liquid outlet.

2 phase Decanter Centrifuge:

After entering into the high-speed turning drum, the solid-phase particles in the mixed liquid run and settle on the drum

wall under the action of greatest centrifugal force; the light liquid settles at the innermost place of the drum under minimum centrifugal force; same as the drum's turning direction, a screw feeder also turns at a high speed, and a constant speed difference is generated by the differential mechanism, then the liquid will be discharged by the liquid outlet.

Application field

1. Food

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Details Images

Product Paramenters

|

Model

|

Bowl Dia

|

Bowl Length

|

Speed rpm

|

Capacity

|

Main Motor Power

|

Weight

|

Size

|

|

LW220

|

220 mm

|

930mm

|

5000

|

0.5-5 T/h

|

7.5 KW

|

1200kg

|

2420*700*1010mm

|

|

LW300

|

300 mm

|

1200mm

|

4000

|

0.5-5 T/h

|

11KW

|

1500kg

|

2680*830*1280mm

|

|

LW355

|

355 mm

|

1600mm

|

3800

|

1-10 T/h

|

15 KW

|

1850kg

|

3490*860*1200mm

|

|

LW400

|

400 mm

|

1800mm

|

3650

|

2-15 T/h

|

18.5KW

|

2500kg

|

3890*1020*1200mm

|

|

LW450

|

450 mm

|

2000 mm

|

3650

|

3-20 T/h

|

22 KW

|

3000kg

|

4297*1080*1385mm

|

|

LW500

|

500 mm

|

2000mm

|

3000

|

5-45 T/h

|

30 KW

|

3800kg

|

4330*1140*1470mm

|

|

LW530

|

530 mm

|

2280mm

|

2900

|

10-60 T/h

|

45 KW

|

5000kg

|

4924*1170*1540mm

|

|

LW550

|

550 mm

|

2200mm

|

2780

|

15-80 T/h

|

55 KW

|

5580kg

|

4395*1370*1655mm

|

|

LW580

|

580 mm

|

2500mm

|

2500

|

20-80 T/h

|

55 KW

|

6500kg

|

5205*1270*1540mm

|

|

LW650

|

600 mm

|

2800mm

|

2270

|

30-120 T/h

|

75 KW

|

7000kg

|

4200*1900*1350mm

|

Recommend Products

Packing

Hot Searches