- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.1

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

PF

-

Dimension(L*W*H):

-

1360mmX1430X1800mm

-

Weight:

-

1500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Machinery Capacity:

-

8000BPH

-

Packaging Material:

-

Glass

-

Filling Material:

-

Other

-

Filling Accuracy:

-

0.1

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

PF

-

Dimension(L*W*H):

-

1360mmX1430X1800mm

-

Weight:

-

1500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

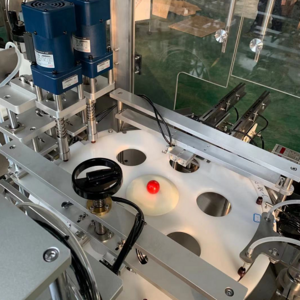

Model YKS1A Cartridge filling machine

(cartridge stopper, filling and capping machine)

1. Main Application:

This machine is suitable for 1.5-3ml cartridge bottle to stopper, filling, capping.

This machine adopt 4 stations to Stepping conveying system, batch type Disc rotating wheel structure, automatically finished moving bottle, stopper, filling, capping and putting the finished bottle.

This machine can use alone. Also it can contact with washing, sterizier , drying machines into a line.

2. Technique parameters:

Suitable specification: 1.5-3ml cartridge

Capacity: about 1800bottles/h

Filling heads: 2pcs( It filled by two times)

Filling precision: ±1%

Stopper percent: ≥99%

Capping percent: ≥99%

Power: 3kw 380V 50Hz/60Hz

Weight: 1500kg

Dimension; 1360mm×1430×1800mm ( L×W×H ) (This include the plexglass door and laminar flow cover)

3. Working principle:

a. This machine adopt 4 stations to Stepping conveying system, batch type Disc rotating wheel structure, one time send one bottle to each production process. It automatically finished to sending the bottle, stopper, filling, and capping process. This machine is suitable to stopper, fill and cap for the cartridge injection in aseptic condition.

b. This machine adopt the batch type Disc rotating wheel structure to stopper, filling, capping and sealing. Cartridge bottle is sending by revolving shaft to round plate turntable . In this station, it have a photoelectrical device switch which can control no bottle no stopper, no filling. The round plate turntable send the cartridge to next 5 intermission stations. This 5 intermission stations is as following: add stopper station at the bottom, the first time filling station, the second time filling station, putting cap on the cartridge station, capping and sealing station.

At the stopper station, the stopper vibration hopper arrange the stopper to ordered situation, and send the stopper into stopper detent mechanism. When round plate turntable send the cartridge into the stopper station, the server motor system drive the stopper rod to move from below to upper. Upper bottle battle move downer to make bottle fasten and same time inner cone guide part clutch the bottom of cartridge bottle and push the butyl stopper into the bottle. Stopper pushing rod come back fast from upper to starting point and finished stopper process.

At the filling station, when the cartridge bottle come to filling station, 2 new plunger type rotary no valve pump filling head move from upper to below by servo motor to fill the medicine liquid into cartridge bottle. After finished fill, it come back the upper position. The filling dosage of filling pump can control by touch screen. It can adjust two filling heads or only one filling heads. Finished filling by two times: the first filling head, fill less than half filling dosage, the second filling head fill the rest dosage to the requirement dosage.

At the putting cap station, vibration hopper send the aluminum cap to track direction-finder device, cartridge bottle send to putting cap station to cap.

At the capping and sealing device, one capping head cap the aluminum cap . After finished cap, it push into the rotary turntable.

4.Component list of Cartridge filling, stopper, capping machine

|

Servo motor and servo actuator |

Schneider |

|

PLC |

Mitsubishi or Panasonnic |

|

High precision ball screw |

Taiwan |

|

Switch |

Taiwan Mingwei |

|

Photoelectricity detection switch |

Korea Otto Nikos |

|

Contactor, breaker |

Siemens |

|

Small relay |

Panasonnic or Omron |

|

Plexiglass door switch |

Panasonnic |

|

Vibrate device , move stopper track, fall cap track |

316L Stainless steel |

|

Stopper rod, filling head, stopper press bottle cover |

316L Stainless steel |