- Product Details

- {{item.text}}

Quick Details

-

Material loading:

-

Automatic

-

Screen change mode:

-

Automatic screen change

-

T-die brand:

-

JC-TIMES

-

Thickness gauge:

-

Optional (Chinese brand or SCANTECH)

-

Automatic Grade:

-

Automatic

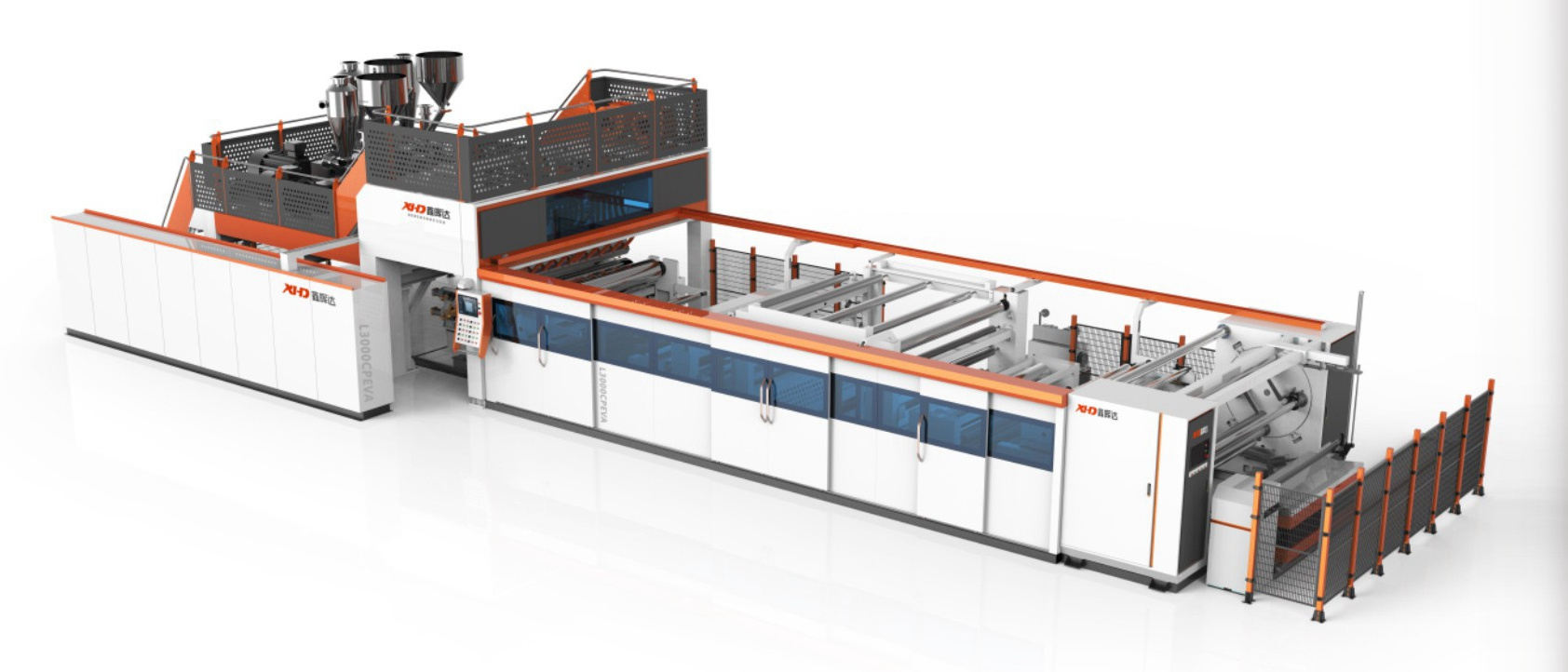

Quick Details

-

Production Capacity:

-

600 M/MIN

-

Place of Origin:

-

Guangdong, China

-

Final with of the film:

-

2400 mm

-

Material loading:

-

Automatic

-

Screen change mode:

-

Automatic screen change

-

T-die brand:

-

JC-TIMES

-

Thickness gauge:

-

Optional (Chinese brand or SCANTECH)

-

Automatic Grade:

-

Automatic

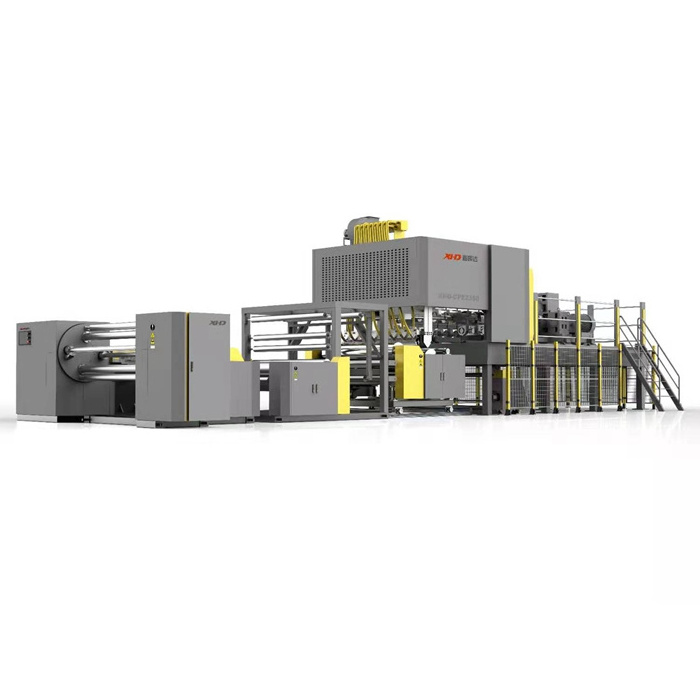

baby diapers backsheet production line

|

NO. |

ITEM |

DESCRIPTION |

|

1. |

Power supply: |

Customized |

|

2. |

Main production raw material: |

PE breathable resins |

|

3. |

Specification of finished product: |

16G~35G, Width: 2400 mm |

|

4. |

Maximum extrusion capacity: |

600 KGS/MIN |

|

5. |

Designed linear speed: |

250 M/MIN |

|

6. |

Total installation power: |

350 KW (for reference only!) |

|

7. |

Number of film layers: |

Single layer |

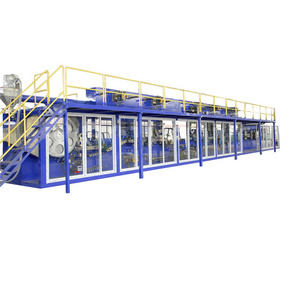

Features of the machine

1. Equipped with professional extrusion and recycling system for edge trim online.

2. Equipped with advanced vertical or horizontal stretching unit, convenient and safe to haul-off the film. The stretching ratio can be adjusted according to product's requirements.

3. The whole line is controlled by touch screen and PLC, and all kinds of buttons designed specially are complete, convenient and safe to operate.

4. Equipped with the latest winding tension control unit, with accurate, stable and reliable tension measurement and control.

5. Optional online slitting unit and online printing unit, it can realize automatic flow operation, save working procedures and labor cost.

Characteristics of product

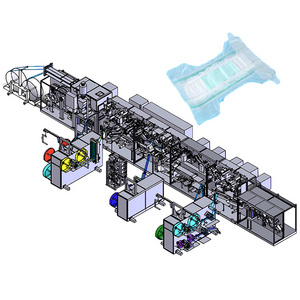

1. The new generation breathable film is with unique cellular structure. This special high-density cellular structure with distributes on the surface of film can prevent the leakage of liquid and let air like water vapor to pass, so it is with the function of "breathable and water proof".

Therefore, the water vapor in water absorption layer of sanitary napkin and baby diaper can go out through the film, which makes the skin is more dry.

2. The film has the advantages of softness, non-poisonous, pure white, high purity and so on.

Main applications of product

1. Hygienic products: sanitary napkin, sanitary pads, baby diaper and so on.

2. Medical products: medical surgical isolation gown and disposable bedspread etc.

3. Commodities: raincoat, gloves, raglan sleeve, waterproof cloth and so on.

4. Building materials: breathable and waterproof material, anti-dew film and so on.

About XINHUIDA MACHINERY

Ø National High and New Tech enterprise.

Ø Registered capital: 10 Million RMB.

Ø More than 14 years’ experience on cast stretch film machine manufacturing.

Ø 41 patents, CE certification and ISO9001: 2015 certification.

Ø 25000 SQM modern factory and various advanced processing equipment.

Ø Manufactured 3000+ sets of stretch film machines.

Ø Manufactured 50+ sets of 2000 mm stretch film production lines in the past 3 years.

Ø Machines are exported to 64 countries and cities.