Carbonized wood for produce coal briquette

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

H): 2.1*2.3*1.9m

-

Voltage:

-

380V

-

Power:

-

7.5kw

-

Warranty:

-

12 Months

-

Local Service Location:

-

None

-

After Warranty Service:

-

Video technical support, Online support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

Biomass Wastes,wood, bamboo...

-

Carbonization:

-

For briquettes: 6-8 hours

-

Heating mode:

-

Not self-burning in the carbonization furnace

-

Kiln car:

-

3 sets and rails

-

Name:

-

charcoal carbonization furnace

-

Color:

-

Customer's Request

-

Delivery:

-

10 days after payment received

-

Weight:

-

4200kg

-

Certification:

-

CE ISO9001

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

LEABON

-

Effective Volume:

-

5CBM

-

Dimension(L*W*H):

-

H): 2.1*2.3*1.9m

-

Voltage:

-

380V

-

Power:

-

7.5kw

-

Warranty:

-

12 Months

-

Local Service Location:

-

None

-

After Warranty Service:

-

Video technical support, Online support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

Biomass Wastes,wood, bamboo...

-

Carbonization:

-

For briquettes: 6-8 hours

-

Heating mode:

-

Not self-burning in the carbonization furnace

-

Kiln car:

-

3 sets and rails

-

Name:

-

charcoal carbonization furnace

-

Color:

-

Customer's Request

-

Delivery:

-

10 days after payment received

-

Weight:

-

4200kg

-

Certification:

-

CE ISO9001

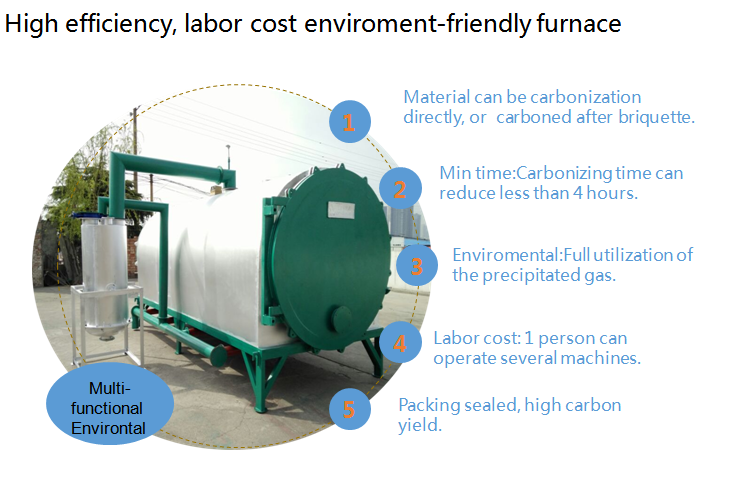

Product Introduction of saw dust carbonizing furnace/charcoal retort kiln

It adopts the advanced carbonized technology heat flow,carbonized rate increased significantly,The carbonized rate is about 80%, up by 99% .And the operation is very convenient, good safety,high production efficiency,can save a lot of energy, good environmental protection performance.Shunt can also dry burning boiler flue gas and so on.Truly the charcoal,gas and oil range of equipment.Is currently the world's most advanced carbonation furnace.

|

Model

|

LBCF-10

|

LBCF-3

|

|

Feeding Capacity (Kg/batch)

|

5500kg/batch

|

1800 kg/batch

|

|

Capacity

(wood)

|

Wood:charcoal=3:1

|

Wood:charcoal=3:1

|

|

|

Capacity: 3.7 t/day(charcoal)

|

Capacity: 1.2 t/d(charcoal)

|

|

|

2 furnaces/day

|

2 furnaces/day

|

|

Capacity

(Wood briquettes)

|

Wood briquettes:charcoal=2.5:1

|

Wood briquettes:charcoal=2.5:1

|

|

|

Capacity: 4.4 t/day(charcoal)

|

Capacity: 1.4 t/day(charcoal)

|

|

|

2 furnaces/day

|

2 furnaces/day

|

|

Carbonization Time

|

For wood (>15%): 8-10 hours

|

For wood (>15%): 8-10 hours

|

|

|

For briquettes: 6-8 hours

|

For briquettes: 6-8 hours

|

|

Cooling Time

|

8-10 hours

|

8-10 hours

|

|

|

6 hours(with water)

Usage: making coal briquettes |

6 hours(with water)

Usage: making coal briquettes |

|

Dimension

|

4800*2600*2200mm

Diameter of inside: 1.6m |

2800*1650*2000mm

Diameter of inside: 1.2m |

|

Weight

|

4700kg

|

2600kg

|

Advantages of saw dust carbonizing furnace/charcoal retort kiln

1.Due to its design principle of rotary type, reduce its carbonization time.

2.it can use different material as the fuel.

3.Saving energy, it can reuse the smoke produced during the process of carbonization.

4.Compare with the hoist type carbonization, its biggest advantage is it doesn't need any hoist equipment.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.