- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

circuit board

-

Power:

-

30KW

-

Input voltage:

-

3P 380V 50-60Hz

-

Heating current:

-

400-1500A

-

Cooling way:

-

Water cooling

-

Aluminum thickness:

-

1.5-2mm

-

Size:

-

1800x1100x1800

-

weight:

-

400kg

-

Application:

-

Brazing

-

Certification:

-

CE

-

Color:

-

Yellow and white

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YUELON

-

Marketing Type:

-

Hot Product 2021

-

Core Components:

-

circuit board

-

Power:

-

30KW

-

Input voltage:

-

3P 380V 50-60Hz

-

Heating current:

-

400-1500A

-

Cooling way:

-

Water cooling

-

Aluminum thickness:

-

1.5-2mm

-

Size:

-

1800x1100x1800

-

weight:

-

400kg

-

Application:

-

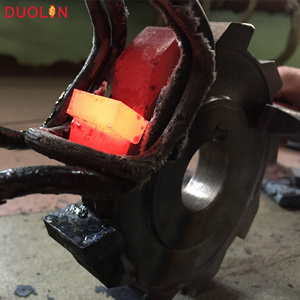

Brazing

-

Certification:

-

CE

-

Color:

-

Yellow and white

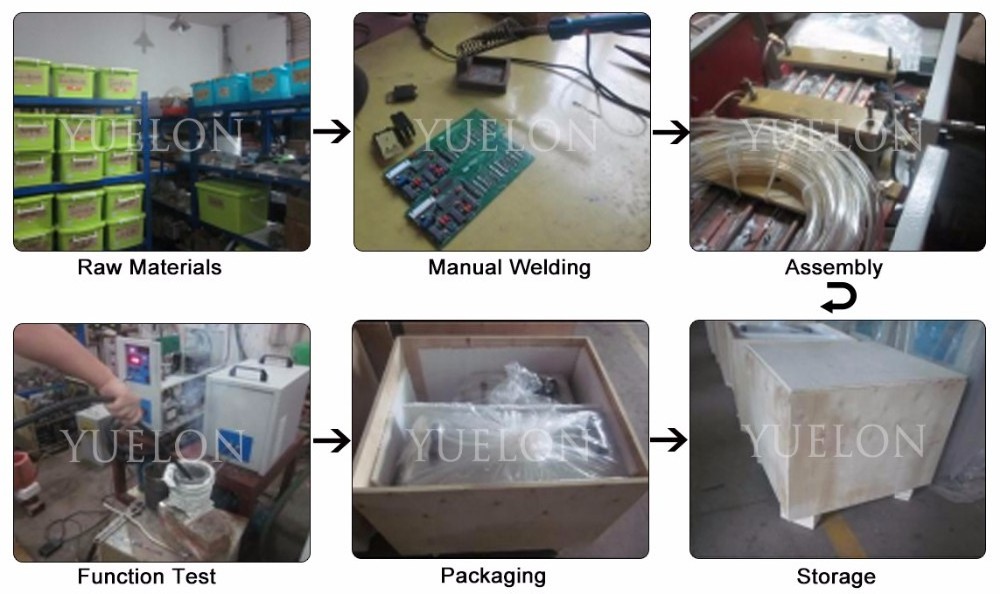

High frequency induction brazing machine is a new welding method has its advantages:

• Energy saving and environmental protection

• High welding efficiency, high production rage, stable working, precise positioning.

• High quality welding: welding surface smooth, consistent welding quality, improve the overall quality of welding products

• Simple and easy operation, a few seconds to learn

• Low manufacturing cost, is about the traditional oxidation welding 1 / 4.

Main features of induction heating machine:

• High Frequency induction heating machine adopts the latest IGBT power units and frequency conversion control techniques with high efficiency, low energy consumption and higher output power.

•With constant current and constant power control function to greatly optimize the heating process of metals, realize efficient and fast heating, and fully exert the superiority of the products.

•Power consumption is half of traditional electron tube high frequency induction heating equipments under the same conditions.

•With 100% load design, can work for continuous 24-hour a day. Infrared temperature detector can be equipped to realize the automatic control of temperature, improve heating quality and simplify manual operation.

•With heating-insulating-cooling three stages function setting, the heating and insulating time required can be get to accommodate to the batch and repeated heating situations.

•With multiple status display of overflow, over voltage, low water, phase failure and load malfunction, providing higher reliability and sustainability.

Main specifications:

|

Model |

3B-25 |

3B-30 |

3B-40 |

3B-60 |

|

Power |

25KW |

30KW |

40KW |

60KW |

|

Input voltage |

3P 380V 50-60Hz |

3P 380V 50-60Hz |

3P 380V 50-60Hz |

3P 380V 50-60Hz |

|

Heating current |

200-1200A |

400-1500A |

400-1800A |

400-2400A |

|

Cooling way |

Water cooling |

Water cooling |

Water cooling |

Water cooling |

|

Brazing diameter |

≤φ130mm |

≤φ140mm |

≤φ180mm |

≤φ250mm |

|

Aluminum thickness |

1.5-2mm |

1.5-2mm |

1.5-2mm |

1.5-2mm |

|

Size |

1800x1100x1800 |

1800x1100x1800 |

1800x1100x1800 |

1800x1100x1800 |

|

weight |

360KG |

400kg |

450kg |

500kg |