- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

1300 mm

-

Travel (Y Axis)(mm):

-

2500 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

5.8kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

UBOCNC

-

Voltage:

-

220V/380V 50HZ

-

Dimension(L*W*H):

-

3200x2140x1850mm

-

Power (kW):

-

5.8

-

Weight (KG):

-

1500

-

Product name:

-

ATC CNC Router engraving machine for wood furniture sofa making

-

After-sales Service Provided:

-

24 Hours Online engineer Service

-

Name:

-

Atc 3d Wood Cnc Router

-

Application:

-

Wood Acrylic PVC Engraving Cutting

-

Function:

-

Cutting Engraving Carving Milling Drilling

-

Type:

-

Popular Wood Cnc Router

-

Working table:

-

Vacuum Table + Tslot

-

Spindle Cooling Way::

-

Water cooling by water chiller

-

Working Area::

-

1300*2500*200mm

-

Driving Syestm::

-

Japanses Yaskawa servo motors and drivers

Quick Details

-

Working Table Size(mm):

-

1300×2500

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

18000 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

1300 mm

-

Travel (Y Axis)(mm):

-

2500 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

5.8kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

UBOCNC

-

Voltage:

-

220V/380V 50HZ

-

Dimension(L*W*H):

-

3200x2140x1850mm

-

Power (kW):

-

5.8

-

Weight (KG):

-

1500

-

Product name:

-

ATC CNC Router engraving machine for wood furniture sofa making

-

After-sales Service Provided:

-

24 Hours Online engineer Service

-

Name:

-

Atc 3d Wood Cnc Router

-

Application:

-

Wood Acrylic PVC Engraving Cutting

-

Function:

-

Cutting Engraving Carving Milling Drilling

-

Type:

-

Popular Wood Cnc Router

-

Working table:

-

Vacuum Table + Tslot

-

Spindle Cooling Way::

-

Water cooling by water chiller

-

Working Area::

-

1300*2500*200mm

-

Driving Syestm::

-

Japanses Yaskawa servo motors and drivers

Automatic Tool Changer Wood CNC Router engraving cutting Machine

UW-A1325Y Series ATC CNC Router is a great machine if you want to streamline your CNC production process. Routing is driven by Syntec industrial CNC controller with an easy to use system interface. The machines includes a 9kw(12 HP) high frequency automatic tool changer spindle with an 8 or10 position tool holder rack . Your product shop benefits from high speed precision motion, a maintenance free and efficient CNC cutting system, and increased production and profits.

It can process wood, foam, MDF, HPL, particleboard, plywood, acrylic, plastic, soft metal and many other different materials.

Feature Of Machine

· Effective working area: 13 00* 25 00*300mm

· Heavy duty thicker structure

· Carousel type automatic tool changer with 8 tool storage

· Taiwan Syntec/ LNC control system

· Japanese YASKAWA 85 0w servo motor and 850w servo driver

· Helical rack & Gear

· Taiwan TBI ball screw

· Taiwan PMI square linear guide way 25mm for X,Y,Z axis

· Automatic Tool sensor calibration

· Automatic oil lubrication system

Application

Wood furniture industry:

Doors, Cabinets, Tables, Chairs, Wave plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates, cupboard doors, interior doors, sofa legs, headboards, and so on.

Advertising industry:

Signage, Logo, Badges, Display board, Meeting signboard, Billboard

Advertising filed, sign making, acrylic engraving and cutting, crystal word making, blaster molding, and other advertising materials derivatives making.

Mold industry:

Sculpture of copper, aluminum, iron, and another metal mold as well as artificial marble, sand, plastic sheeting, PVC pipe, and another non-metallic mold.

Artwork and Decoration:

wood crafts, gift box, jewelry box.

Others:

Relief sculpture and 3D engraving and cylindrical object.

M ain Configuration:

|

Model |

UW-A1325Y |

|

Working Area: |

1300*2500*2 0 0mm |

|

Spindle Type: |

water cooling spindle |

|

Spindle Power: |

9.0KW Italy HSD ATC Air spindle |

|

Spindle Rotating Speed: |

0-24000rpm |

|

Power (except spindle power): |

5.8KW (include powers of: motors, drivers, inverters and so on) |

|

Power Supply: |

AC380/220v±10, 50 HZ |

|

Worktable: |

Vacuum Table and T-slot |

|

Driving Syestm: |

Japanses Yaskawa servo motors and drivers |

|

Transmission: |

X,Y :Gear rack, high accuracy square guide rail,

|

|

Locating precision: |

<0.01mm |

|

Min Shaping Character: |

Character:2x2mm,letter:1x1mm |

|

Operating Temperature: |

5°C-40°C |

|

Working Humidity: |

30%-75% |

|

Working Precision: |

±0.03mm |

|

System Resolution: |

±0.001mm |

|

Control Configuration: |

Mach3 |

|

Data Transfer Interface: |

USB |

|

System Environment: |

Windows 7/8/10 |

|

Spindle Cooling Way: |

Water cooling by water chiller |

|

Limited Switch: |

High sensitivity limited switches |

|

Graphic Format Supported: |

G code: *.u00, * mmg, * plt, *.nc |

|

Compatible Software: |

ARTCAM, UCANCAM ,Type3 and other CAD or CAM softwares…. |

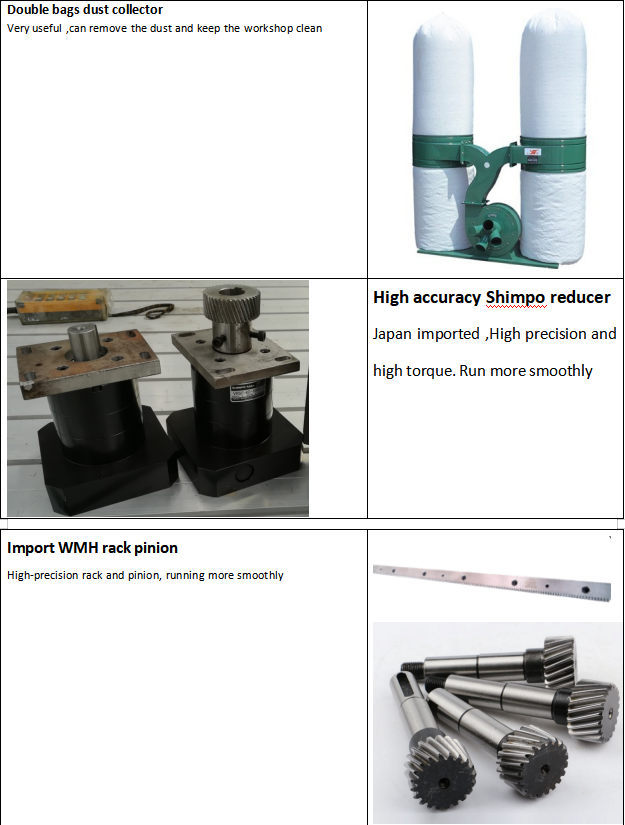

Main parts:

samples

1.Our company specializes in CNC equipment production more than 10 years with rich experience .

2.Our company is a manufacturer, not a trader. have high quality with competitive price.

3.We can provide engineer for overseas service .

4.If there are any problems in the process of using the equipment, you can ask us at any time, and we will try our best to help you solve them.

5.24months warranty and whole life service ,during warranty can provide parts for free.

Q: What's your MOQ? What's your delivery term?

A: Our MOQ is 1 set machine, we usually require 10- 1 5 days for manufacturing, 2days for testing well and 1 day for packaging. The exact time will be depended on your order quantity and customized level.

Q: Whats your warranty time ? What you can supply to us after we bought your machine?

A: We give customer 2 year quality warranty. if you have any question, we will give permanent technic support and spare parts supplying.

Q: This is the first time I use this kind of machine, is it easy to operate?

A: There are english manual or teaching video that show how to use machine. If there is still have any question, please contact us by e-mail / skype/ phone /trademanager online service at any time.

Q: If I do not find the type what I need,what I should do?

A: We can produce customized products according to your drawing or samples.

Q: How do we do the shipment?

A: We can help you booking the ship and shipping to your port directly , or we help you search the ship,then you talk with shipping company directly .