- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

2600

-

Weight (KG):

-

410 KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KEXINDA

-

Voltage:

-

220V/380V 50HZ

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

15 kW

-

Contact material:

-

SUS304/316

-

Function:

-

dispersion, stirring,mixing

-

Color:

-

customized

-

Model:

-

single screw & double screw

-

Control:

-

Botton

-

Weight:

-

customized

-

Lifting:

-

hydraulic/Mechanical lifting

-

Machine Type:

-

Agitator

-

Packing:

-

Standard case package

-

Usage:

-

Mixing Proucts

Quick Details

-

Barrel Volume (L):

-

3600

-

Max. Loading Volume (L):

-

2600 L

-

Range of Spindle Speed(r.p.m):

-

0 - 1610 r.p.m

-

Max. Loading Capacity:

-

2600

-

Weight (KG):

-

410 KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KEXINDA

-

Voltage:

-

220V/380V 50HZ

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

15 kW

-

Contact material:

-

SUS304/316

-

Function:

-

dispersion, stirring,mixing

-

Color:

-

customized

-

Model:

-

single screw & double screw

-

Control:

-

Botton

-

Weight:

-

customized

-

Lifting:

-

hydraulic/Mechanical lifting

-

Machine Type:

-

Agitator

-

Packing:

-

Standard case package

-

Usage:

-

Mixing Proucts

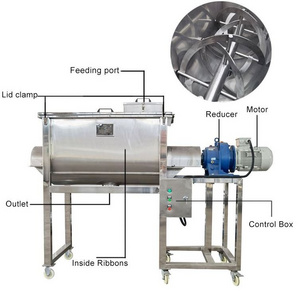

Car Paint Making Machine Wall Paint Manufacturing Machine Water-Based Paint Mixing Machine

Product Details

2. Mixing shaft : single shaft & double shaft

3. Function : mixing and dispersing

4. Lifting Way : hydraulic lift,mechanical lift

5. Motor power : Customized

6. Contact Material : SS304/316

7. Speed : controlled by frequency converter.0-1650RPM/min,adjustable

This is some type of dispersion disc head to choose from.

If you want to provide a private order, you can contact me.

Application

This kind of machine is a high-efficiency equipment for stirring, dispersing and dissolving a variety of mixed liquids and solids. It is widely used in chemical products such as paints, pigments, inks and adhesives.

Dispersing machine is the most commonly used, economical and simple machine for paint processing.

Main Features

1.One machine with multi-vessels,stable capability

2.Hydraulic lifting

3.With electric or manual steering system, easy and convenient to steer the headstock.

4.The adjustable working position enable the machine to work with several tanks, which enhances the machine usage rate greatly, reduce equipment investment and save space.Easy to operate and clean

5.Various speed control

6.Low noise and long-time continuous operation.

7. Siemens or ABB motor for you and Siemens/Emerson Frequency inverter available

8. Non explosion-proof and explosion-proof type of production dispersing equipment are both as standard

9. Vacuum production high speed disperser is available.

10.Little air absorption during mixing and dispersing process makes it disperses and dissolves materials to smaller particle size efficiently .

11.Customized equipments are available.

We are the professional manufacturer for chemical machine, we have do this machine manufaturer more than 15years,have rich experience and mature technical design and export this machine.

Depend on rich experience and advance technical, we export machine to USA, UAE, Russia, Italy, Armenia, Saudi Arabia, Pakistan, India, Indonesia, Brazil, Ecuador, South Korea, South Africa, Singapore, Vietnam and Poland.etc.

The chemical and plastic industry machine we can provide like:

SMC production line, BMC production line, resin production line, coating production line, adhesive production line, Hot melt glue stick production line,Waste plastic recycling machine,Plastic granulation machine,Powder mixing machine,Liquid mixing machine,Reactor, Z arm mixer, dispersing machine, colloid mill, three roller mill, ball mill, sand mill.

|

Packaging

|

|

|

|

Size

|

Customized

|

|

|

Weight

|

Customized

|

|

|

Packaging Details

|

Standard case package

Three plywood case package.

|

|

About Delivery time

Q-----What's the delivery term for making business with us?

A-----Usually we send the shipment in FOB term.However, the terms of CIF are acceptable which depend on the preference of clients.

About Lead Time

Q------What's the lead time after placing the order?

A------Usually it takes about 15~30 days after we received your confirmation.

However, it would depend on our production line schedule(the timing clients place order)and the complication of the item.

About Payment Term

Q------What's the Payment Term?

A------By T/T in Advance, or Irrevocable L/C as Sight.

We will offer you price referring to your detail request, so please kindly inform us of the material, viscosity, density, etc, and other requirements you prefer, and the special offer will be given.

The pictures are above just for your reference.

Our machines can be

customized

, leave an inquiry to know more details about price, packing, shipping and price.Any questions, feel free to contact us.