- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3300 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

145 mm

-

Brand Name:

-

Krrass

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6000 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V/ 220V /415V optional

-

Dimension(L*W*H):

-

3840*1610*1620mm

-

Year:

-

2022

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

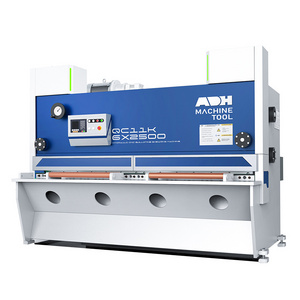

Hydraulic shearing machine

-

Model:

-

QC12K Swim Beam Model

-

Brand:

-

KRRASS or OEM

-

Function:

-

Sheet metal cutting 0~40mm

-

Control system:

-

E21S/ELGO P40/E200PS/DAC360

-

Electrics:

-

France Schneider

-

Main Motor:

-

Germany Siemens Motor

-

Hydraulic System:

-

Germany Bosch Rexroth

-

Tube Connector:

-

Germany EMB

-

Oil Pump:

-

USA Sunny

Quick Details

-

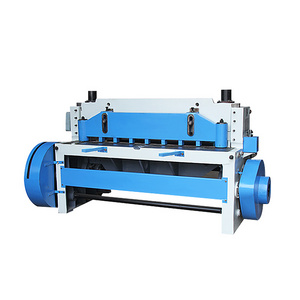

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

6 mm

-

Shearing Angle:

-

1°30"

-

Blade Length (mm):

-

3300 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

145 mm

-

Brand Name:

-

Krrass

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6000 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V/ 220V /415V optional

-

Dimension(L*W*H):

-

3840*1610*1620mm

-

Year:

-

2022

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

Hydraulic shearing machine

-

Model:

-

QC12K Swim Beam Model

-

Brand:

-

KRRASS or OEM

-

Function:

-

Sheet metal cutting 0~40mm

-

Control system:

-

E21S/ELGO P40/E200PS/DAC360

-

Electrics:

-

France Schneider

-

Main Motor:

-

Germany Siemens Motor

-

Hydraulic System:

-

Germany Bosch Rexroth

-

Tube Connector:

-

Germany EMB

-

Oil Pump:

-

USA Sunny

You can get more information about us via:

Youtube account:

Hydraulic Guillotine Shearing Cutting Machine for Metal, Ss, Ms, Al

1. Streamlined design originated from EU ( European Union), using overall frame welding and annealing treatment.

2. Germany Rexroth integrated hydraulic system, hydraulic drive, stable and reliable, integrated hydraulic system design, effectively reduce the hydraulic oil leakage problems. 3. Hydraulic swing beam shear is one kind of equipment through swinging the upper blade to shear plate, smaller shear angle, reducing distortion, improving shearing quality.

4.Motor adjusts the Backgauge through high precision ball screw, frequency convertor controls the position to prevent horizontal swinging. Light align device, convenient for manual operation, pressure cylinder with built-in spring mechanism and completed with special material gasket under bottom end in case generating imprint on aluminum or other sensitive materials.

5. Made by high-quality alloy tool steel, the machine can meet the impacting load and high wear resistance requirements when working. Light and practical suspension arm, reference man-machine engineering design, easy to operate the numerical control interface, high precision and more comfortable.

6. The worktable adopts the rolling steel ball to reduce the frictional resistance to protect the surface of workpieces, the novel protective devices all in line with the safety specifications, protects the operator’s personal safety, ingenious design, and petty material cutting can be done easily.

7. Vertical alignment of the front bracket and front positioning device ensure the cutting accuracy, easy operation, practical and efficient.

8. Rapid adjustment mechanism of Blade clearance, easy and quick stepless adjustment.

|

No |

Accessory Name |

Model / Manufacturer |

Other |

|

|

1 |

NC System |

E21s NC System Estun |

||

|

2 |

Electrics |

Germany Schneider Electric |

Travel switch & Limit switch |

|

|

3 |

Main Motor |

Siemens Motor - Germany |

||

|

4 |

Backgauge, Timing Belt, Timing Pulley |

Taiwan |

Positioning controlGuaranteed Precision |

|

|

5 |

Frequency Converter |

JRACDRIVE |

||

|

6 |

Foot Switch |

KACON - South Korea |

||

|

7 |

Hydraulic System |

Bosch Rexroth - Germany |

||

|

8 |

Oil Pump |

Sunny - USA |

||

|

9 |

Sealing Ring |

PARKER - America/NOK-Japan |

||

|

10 |

Tube Connector |

EMB - Germany |

||

|

11 |

Front Safety Guard |

KRRASS |

||

|

12 |

Back Safety Guard |

KRRASS |

||

|

13 |

Back Blanking Plate |

KRRASS |

||

|

14 |

Backgauge |

Ball Screw HIWIN with 0,05mm accuracy -Taiwan |

||

|

15 |

Top and B ottom Blade |

Top blade with two cutting edges and bottom blade with four cutting edges.(6CrW2Si) |

||

|

|

|

|

Laser Cutting Machine |

Press Brake |

V Groover Machine |

|

|

|

|

| Plate Rolling Machine | Ironworker Machine |

Q1: Why customer choose us?

A: Nanjing Krauss CNC Machinery Co., Ltd. (KRRASS) is a professional, serious and responsible sheet metal machinery manufacturer.

It is precisely because of this attitude that our business continues to grow.

Our factory is one of the largest and best in the local area. Our machines are of good quality and are sold to 92 countries around the world. They are well received by customers.Many customers have become our regular customers.

Q2: Are you a manufacturer or trading company?

A: We are professional manufacturer with big modern factory in Maanshan,Anhui,China. Both OEM & ODM service can be accepted.

Q3: What's your delivery time?

A: Generally 25 to 35 days, if urgently order, pls contact our sales in advance.

Q4: How long is your machine warranty?

A: 2 years warranty for the main components, 10 years for the whole structure.

Q5: How long could your machine be used?

A: Generally, more than 10 years.

Q6: What's payment term?

A: T/T, L/C, Western Union, Paypal, Credit Card, and etc. Also we could accept USD, RMB, Euro and other currency.

Q7: How about your customer service?

A: 24 hours on-line service available. 48hours problem sovled promise.

Q8: How about your after-sales service?

A: 1. Provide customers with intallation and commissioning online instructions.

2. Well-trained engineers available to overseas service.

3. Worldwide agents and after service avaiable.