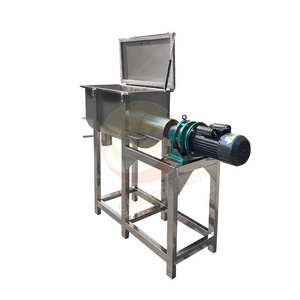

This horizontal powder machine adopts high quality 304 stainless steel with fine polishing surface, which has strong corrosion

resistance and steady performance so as to improve the processing efficiency.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

900 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Yuanyang

-

Voltage:

-

380v/50hz customized

-

Dimension(L*W*H):

-

2800*1200*1500mm

-

Power (kW):

-

7.5 kW

-

Marketing Type:

-

2023new

-

Product name:

-

Horizontal Ribbon Mixer

-

Function:

-

Mixing Dry Food Ingredient

-

Keyword:

-

Powder Mixer

-

Usage:

-

To mix different raw powder together

-

Stirrer type:

-

Ribbonn Blender

-

Capacity:

-

200L 500L 1000L 1500L

-

Feature:

-

Cost Effective

-

Control:

-

Button Panel

-

Advantage:

-

Easy Clean Easy Maintainance

Quick Details

-

Barrel Volume (L):

-

200

-

Max. Loading Volume (L):

-

2000 L

-

Range of Spindle Speed(r.p.m):

-

0 - 41 r.p.m

-

Weight (KG):

-

900 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Yuanyang

-

Voltage:

-

380v/50hz customized

-

Dimension(L*W*H):

-

2800*1200*1500mm

-

Power (kW):

-

7.5 kW

-

Marketing Type:

-

2023new

-

Product name:

-

Horizontal Ribbon Mixer

-

Function:

-

Mixing Dry Food Ingredient

-

Keyword:

-

Powder Mixer

-

Usage:

-

To mix different raw powder together

-

Stirrer type:

-

Ribbonn Blender

-

Capacity:

-

200L 500L 1000L 1500L

-

Feature:

-

Cost Effective

-

Control:

-

Button Panel

-

Advantage:

-

Easy Clean Easy Maintainance

High Standard Powder Making Machine Ribbon Mixer Food Grade 200L 500L 1000L Mixing Tank

Products Description

Main Features

The series of Yuanyang powder mixer are used for the uniform mixing of powder,granular and other materials in

cosmetic,chemical,food industries and so on. The machine is simple in structure, easy to operate and clean.The material-contacting parts are made of stainless steel which meet GMP standards.

Operating Principle

A motor and a reducer are installed on the side.

The motor drives the reducer with a belt, and the reducer drives the V-shaped barrel with a coupling.

The powder in the V-shaped barrel is mixed up and down, back and forth in the barrel.

cosmetic,chemical,food industries and so on. The machine is simple in structure, easy to operate and clean.The material-contacting parts are made of stainless steel which meet GMP standards.

Operating Principle

A motor and a reducer are installed on the side.

The motor drives the reducer with a belt, and the reducer drives the V-shaped barrel with a coupling.

The powder in the V-shaped barrel is mixed up and down, back and forth in the barrel.

Customization

1: The mixer is made up of stainless steel 304 ( if consumer need 316. inform us in advance).2: The mixer can add a forced stirring inside mix tank .( if consumer need. inform us in advance) .

3. The mixer can add the liquid spraying system.( if consumer need. inform us in advance) .

3. The mixer also can add the heating or cooling jacket ( if consumer need. inform us in advance) .

4.:The mixer can make into vacuum condition( if consumer need, inform us in advance).

5:The mixer can add the frequency changer( adjust the rotation speed), (if consumer need, inform us in advance).

6.Vacuum feeding machine or spiral conveyer can be equipped to achieve automatic feeding.

3. The mixer can add the liquid spraying system.( if consumer need. inform us in advance) .

3. The mixer also can add the heating or cooling jacket ( if consumer need. inform us in advance) .

4.:The mixer can make into vacuum condition( if consumer need, inform us in advance).

5:The mixer can add the frequency changer( adjust the rotation speed), (if consumer need, inform us in advance).

6.Vacuum feeding machine or spiral conveyer can be equipped to achieve automatic feeding.

Specification

|

Model

|

YYPP-200

|

YYPP-500

|

YYPP-1000

|

YYPP-1500

|

|

Power

|

3kw

|

5.5kw

|

5.5kw

|

7.5kw

|

|

Speed of principle axis

|

5~40 rpm/min

|

5~40 rpm/min

|

5~40 rpm/min

|

5~40 rpm/min

|

|

Volume

|

200L

|

500L

|

1000L

|

1500L

|

|

Discharge port

|

125mm

|

150mm

|

150mm

|

150mm

|

|

External dimensions(m)

|

2.6x0.7x1.45

|

2.8×0.8×1.45

|

3×0.9×1.5

|

3x1.1x2.1

|

Real Images

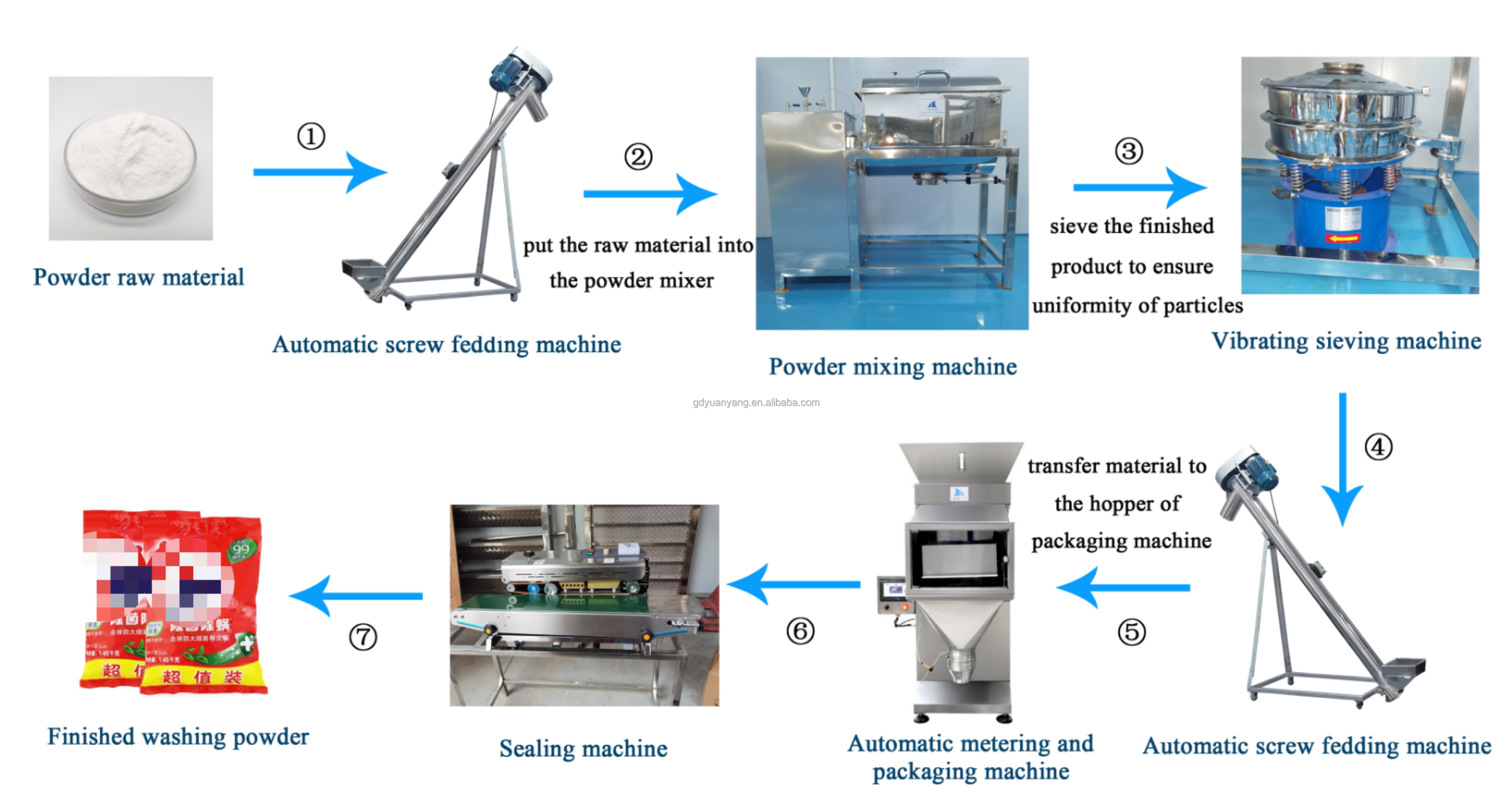

Powder Production Line

Details Images

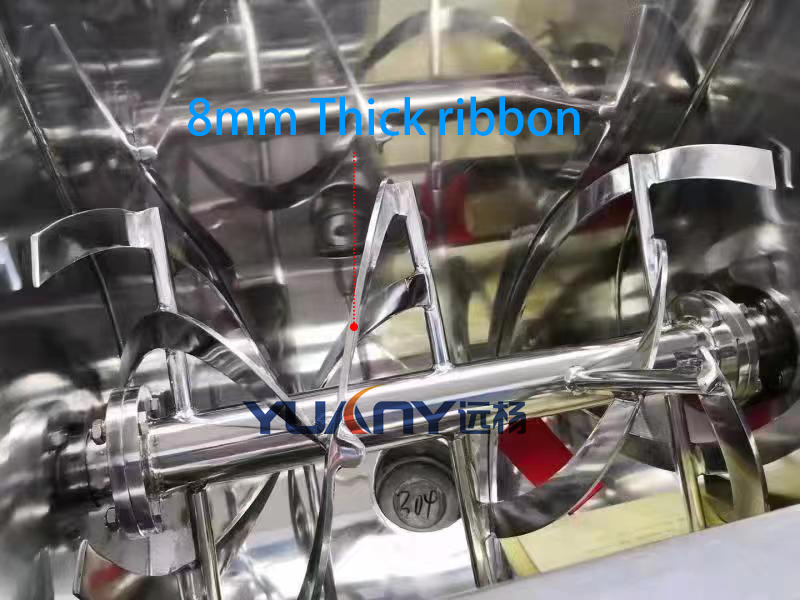

This machine uses double-spiral operation, so that the powder is widely staggered in the machine to produce convection, diffusion and mixing, with high mixing precision and uniform powder quality;

It works with fast mixing speed, which generally takes only about 10 minutes for powder.

The Bigger hole is for vacuum feeding,the small hole is for breathing.

It is added a handle for easy open and close.

With hook, safe working.

High quality core part,to achieve better mixing efficiency.

Easy to operate.

The stirring speed is adjustable,the frequency inverter is added.

Discharge

butterfly discharge manually,easy to handle

There is sealing device on the lid for no dust fly while working.

There is also stainless steel protection grid on the tank,which can be removed. It is for safe feeding,in case any damage to man or bags.

Application

It’s widely used in food, chemical industry to mix dry powder such as milk powder, coffee powder, wheat flour, corn flour, maize flour, rice flour, oats flour, protein powder, cosmetic powder, chili powder, onion powder, spar powder, chicken powder, gourmet powder, egg powder, washing powder, detergent powder, solid drink, dextrose, titanium oxide, powder additive, Moringa powder, agriculture pesticide, dyestuff, and so on.

Powder a

dditives

Chemical powder

Food powder

Make up powder

Chicken powder

Seasoning powder

Hot Searches