- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

<=0.5%

-

CrO Content (%):

-

<=0.5%

-

SiC Content (%):

-

<=0.5%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SK 37 refractory brick

-

Brand Name:

-

CCEFIRE refractory Brick

-

Model Number::

-

SK37 high alumina refractory Brick

-

cold crushing strength::

-

20%

-

color::

-

ivory white

-

Industrial standard::

-

ASTM JIS

-

refractory underloard::

-

1500 ℃

-

refractoriness::

-

1810 ℃

-

porosity::

-

23%

-

certificate::

-

ISO 9001, CE, MSDS

Quick Details

-

SiO2 Content (%):

-

22%

-

Al2O3 Content (%):

-

75%

-

MgO Content (%):

-

<=0.5%

-

CaO Content (%):

-

<=0.5%

-

CrO Content (%):

-

<=0.5%

-

SiC Content (%):

-

<=0.5%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SK 37 refractory brick

-

Brand Name:

-

CCEFIRE refractory Brick

-

Model Number::

-

SK37 high alumina refractory Brick

-

cold crushing strength::

-

20%

-

color::

-

ivory white

-

Industrial standard::

-

ASTM JIS

-

refractory underloard::

-

1500 ℃

-

refractoriness::

-

1810 ℃

-

porosity::

-

23%

-

certificate::

-

ISO 9001, CE, MSDS

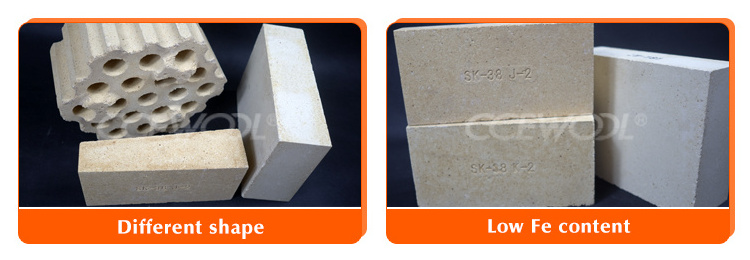

CCEWOOL refractory fire bricks for kiln

It is a kind of refractory material with high refractoriness and mechanical behavior under high temperature.

Fire brick has wide applications, mainly used in metallurgy, construction(cement and glass), petroleum, chemical industry, electric power and machine building.

Fire brick is mainly used for industrial furnaces and kilns and thermal equipment.

| Item | CCEWOOL refractory fire bricks for kiln |

| Types |

High Alumina Brick for Hot-blast Stove Creep Resistant High Alumina Brick Creep Resistant Fire Clay Brick Fire Brick for Hot-blast Stove Combined Brick for Hot-blast Stove |

| Sizes: |

Common size:230x114x75/65mm Also supply special shaped according to your drawing |

| Characteristic |

1.low creep deformation 2.huge heat capacity 3.great refractoriness 4.thermal shock resistance |

| Package | wooden pallet with shrinkage film, paper protect angle. |

CCEWOOL refractory fire bricks for kiln : the size is precise, providing kinds of shapes according to customer's drawing, with low Fe content and high strength.

CCEWOOL refractory fire bricks for kiln

| Item | Fireclay Brick | High Alumina Brick | ||||

| SK32 | SK34 | SK35 | SK36 | SK37 | SK38 | |

| Al2O3(%)>= | 38 | 42 | 48 | 55 | 65 | 75 |

| Refractoriness(°C) | 1670 | 1730 | 1750 | 1770 | 1790 | 1810 |

| Refractoriness under Load(°C) | 1250 | 1300 | 1420 | 1470 | 1500 | 1520 |

| Linear Change(%)(2h) | -0.5 | -0.5 | -0.5 | 0.4- +0.1 | 0.4- +0.1 | 0.4- +0.1 |

| Porosity | 26 | 26 | 22 | 22 | 23 | 23 |

| Cold Crushing Strength,MPa>= | 15 | 20 | 39.2 | 44.1 | 49 | 53.9 |

CCEWOOL refractory bricks will be packed by pallet , also with thermal shrinkage film, packing rope and edge protective paper, so that the brick will be sent to customer with no damage. We have special inspector to follow every order, records the producing and shipping detail, also take photoes before shipping your goods.

Welcome to our website realizes on-line factory inspection

www.cndoubleegret.com

Our brick is ASTM, JIS standard.Also passed ISO 90001 quality certify.

CCEWOOL refractory fire bricks for kiln has got CE certificate, and we can also accept the third part inspection such as SGS, BV, TUV.

1. Over 30 years production experience, equipped with 4 tunnel kilns, 40 press machines, outpurt is 50,000 tons.

2. Providing refractry brick for hot blast furnace and blast furnace.

3. Providing OME service, exported to 30 countries(Germany,France,Italy and so on)

Exhibition infomation

Since 2009, Double Egret has been in international exhibition. Stable quality and good credit win the customer's trust for Double Egret Thermal Insulation.

Why choice us?

Professional fireclay brick manufacturer. We have being specialized in producing refractory fireclay brick for more than 40 years so that we can guarantee a stable quality.

Guaranteed quality. Our production process conforms strictly to the requirements of ISO9000 quality management system. Quality inspection is carried out in every links of our production. SGS third party inspection is available.

Sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

First-class R&D term. We have a first-class R&D team which is specialized in fundamental research and application technology development of ceramic fiber products.