- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

600 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZOEPACK

-

Year:

-

New

-

Voltage:

-

Acoording customer country

-

Dimension(L*W*H):

-

5.8x2.1x2.3 m

-

Hollow part volume:

-

2L

-

Clamping Force (kN):

-

40

-

Power (kW):

-

100

-

Weight (KG):

-

4000 KG

-

Cavity:

-

1-6 Cavity

-

Capacity:

-

1500-12000PCS/H

-

Raw material:

-

PET Plastic Bottle Preform

-

Certification:

-

CE

-

Advantages:

-

High Efficiency

-

After-sales Service Provided:

-

Engineer overseas or Online Support

-

Usage:

-

Drink, Juice, Soda, Beer, Water PET Bottle

-

Marketing Type:

-

Cosmetic, Detergent, Lotion, Edible Oil, Motor Oil

-

Color:

-

Customer Choice

Quick Details

-

Neck Diameter(mm):

-

38 mm

-

Max.Bottle Diameter(mm):

-

100 mm

-

Max.Bottle Height(mm):

-

330 mm

-

Bottle Volume(ml):

-

600 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZOEPACK

-

Year:

-

New

-

Voltage:

-

Acoording customer country

-

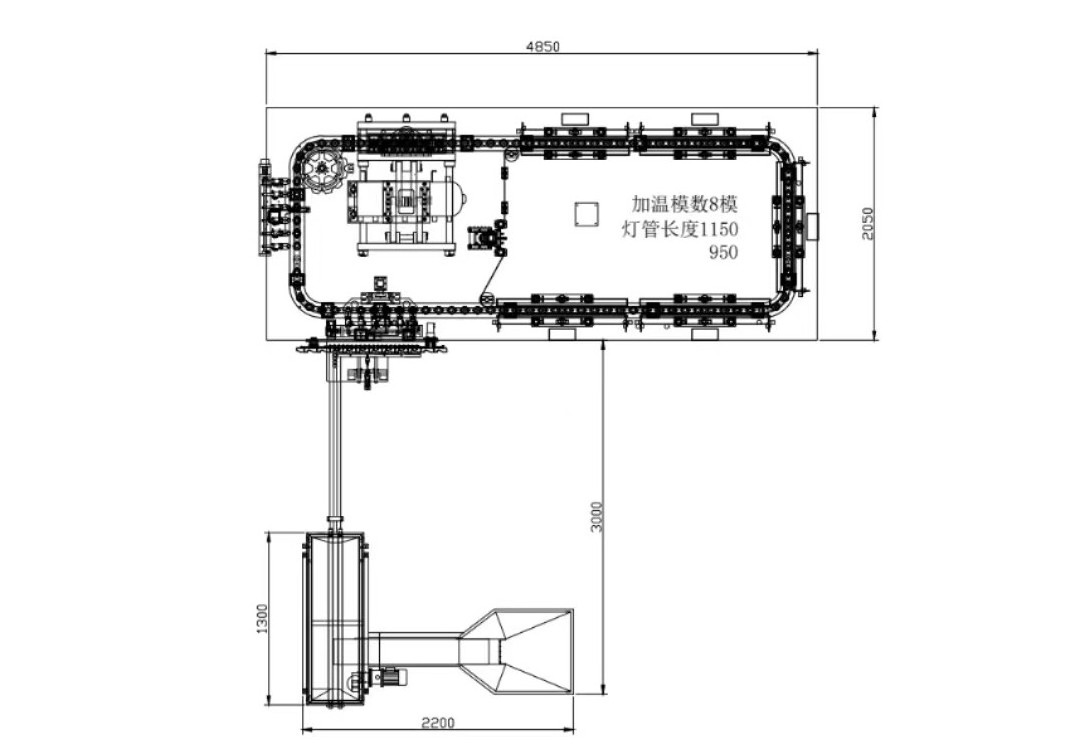

Dimension(L*W*H):

-

5.8x2.1x2.3 m

-

Hollow part volume:

-

2L

-

Clamping Force (kN):

-

40

-

Power (kW):

-

100

-

Weight (KG):

-

4000 KG

-

Cavity:

-

1-6 Cavity

-

Capacity:

-

1500-12000PCS/H

-

Raw material:

-

PET Plastic Bottle Preform

-

Certification:

-

CE

-

Advantages:

-

High Efficiency

-

After-sales Service Provided:

-

Engineer overseas or Online Support

-

Usage:

-

Drink, Juice, Soda, Beer, Water PET Bottle

-

Marketing Type:

-

Cosmetic, Detergent, Lotion, Edible Oil, Motor Oil

-

Color:

-

Customer Choice

Production Description

ZOE PACK

Automatic PET Bottle Blow Molding Machine

Cosmetic / juice /edible oil / medicine / water / CSD

This PET water bottle blow molding machine is specially designed to produce water bottle, PET bottle with high heat resistance for hot filing package such as juice and tea. It adopts multiple blowing to reduce the residual stress, as result shaped bottle has slight shrinkage during hot filling.

In addition, crystallization varies with different mold design, as a result, the PET bottle produced can stand temperature over 90°C depending on the type of PET material with different crystallization rate. The neck up blowing mode protects the bottle preform from damage during blowing and ensures stableperformance. With high strength, good transparency and low production costs, abundant materiaresource, PET Blow Moulding Machine plays a big role in hot filling package market.

Technical Parameters

|

Model

|

|

ZP1500-6C

|

|

|

Bottle type specification

|

Cavity

|

6

|

|

|

|

Max.volume

|

1.5L

|

|

|

|

Bottle mouth maximum overall diameter

|

28-86mm

|

|

|

|

Bottle biggest diameter

|

65mm

|

|

|

|

Bottle maximum height

|

340mm

|

|

|

Production specification

|

Theoretical output

|

10000BPH

|

|

|

|

Bottle type capacity

|

500ML

|

|

|

|

Bottle type weight

|

14g

|

|

|

|

Bottle type

|

circular

|

|

|

Power specification

|

Light tube quantity

|

48pcs

|

|

|

|

Light tube power

|

2KW

|

|

|

|

Maximun heating power

|

60KW

|

|

|

|

All electric machine installation

|

75KW

|

|

|

|

Actual consumption

|

40%--70%

|

|

|

Air pressure specification

|

Work pressure

|

7-9kg/cm

2

|

|

|

|

Low-pressure gas consumption

|

1000L/min

|

|

|

|

Blow bottle pressure

|

25-35kg/cm

2

|

|

|

|

Higher-pressure gas consumption

|

3000Ltr/min

|

|

|

Air pressure specification

|

Work pressure

|

5-6kg/cm

2

|

|

|

|

Temperature range

|

10

℃

|

|

|

|

Comsumption

|

8000kcal/hr

|

|

|

|

Forzen qater flow

|

138L/min

|

|

|

Machine specification

|

Machine size

|

5.8*2.1*2.3

|

|

|

|

Machine weight

|

7.0ton

|

|

|

Component configuration list

|

|

|

|

Components

|

Brand

|

|

|

PLC controller

|

XINJIE CHINA

|

|

|

Touch screen

|

XINJIE CHINA

|

|

|

Cylinder

|

SMC, Japan SMC

|

|

|

Photoelectric switch

|

OMRON, Japan

|

|

|

Contactor

|

Schneider, France

|

|

|

Proximity switch

|

OMRON, Japan 欧姆龙

|

|

|

Sensor

|

OMRON, Japan 欧姆龙

|

|

|

Switch power

|

MEANWELL, Taiwan

|

|

|

Main Servo Motor

|

XINJIE CHINA

|

|

|

Feeding Servo Motor

|

XINJIE CHINA

|

|

Machine Details

Machine Advantages

PET Bottle Blowing Machine Description

1. Stable performance with Advanced PLC.

1. Stable performance with Advanced PLC.

2.

Conveying performs automatically with conveyor.

3.

Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and re-volute in therails simultaneously in the infrared preheated.

4.

High adjust ability to enable the preheated to preheat performs in shapes by adjusting the light tube and the length ofthe reflecting board in the preheating area,and eternal temperature in the preheated with an automatic thermostatic apparatus.

5.

0ptimization of the ovensuction and convulsion devices,cool the preform surface.Waterwayair duct directly through thedevice.double protect the screw neck.

6.

Each mechanical action has safety self locking device,when a process fails, the program will automatically switch to thesecurity status.

7.

Servo device for the material transfer and bottle perform distribution, fast reliable,and high stability.

8.

Using high pressure and hyperbolic arm connecting rod clamping,strong clamping force,speed and distance of clampopen are adjustable.

9.

Safereliable,and unique design of the position of valve to make the air pressure diagram of the machine easier tounderstand.

10.

Along with remote-maintenance systems,remote inspection maintenance,solve the troubles for you.

11.

Low rejection rate: less than 0.2 percent.

Servo driving and cam linking blowing section:

Small performs distance heating

system

Efficient and soft perform inlet system

Mould

Applications

Hot Searches