- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380/220

-

Power (kW):

-

22

-

Weight:

-

2000 KG

-

Raw material:

-

EVA

-

Usage:

-

Wide Usage

-

Product Type:

-

Extrusion Production

-

Keywords:

-

soft hose machine

-

Product:

-

PVC PP HDPE PE Pipe

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380/220

-

Power (kW):

-

22

-

Weight:

-

2000 KG

-

Raw material:

-

EVA

-

Usage:

-

Wide Usage

-

Product Type:

-

Extrusion Production

-

Keywords:

-

soft hose machine

-

Product:

-

PVC PP HDPE PE Pipe

What's the machine can produce

We are professional to produce wigs machine . we provide you the whole technology and all the machines. we will help you how to produce the final wigs.

To make wigs, you need have the following machine :

1. wigs yarn extrusion line. 2. yarn cutting unit . 3. wigs stitching unit. 4. wigs wave making unit.

cosmetic brush yarn , eyelash yarn

eyelash yarn

cosmetic brush .

wigs processing procedures :

yarn making

color and shape forming.

curl making

yarn cutting

prepare for wigs stitching

wigs stitching

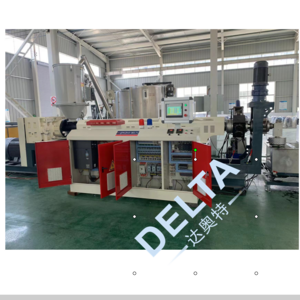

Machine Details Pictures

Machine General Information

|

Screw Diameter mm

|

65

|

80

|

90

|

|

Screw Rotate Speed r/min

|

30-70

|

30-70

|

30-70

|

|

L/D

|

30:1

|

33:1

|

33:1

|

|

Total Power kw

|

40

|

60

|

78

|

|

Productivity kg/h

|

40-80

|

60-120

|

80-180

|

|

Dimension m

|

17.5×2×2

|

21.5×2.1×2

|

26×2.2×2

|

Payment, Delivery , After sell service

payment : 30% T/T or L/C for down payment , 70% before shipment

delviery : 30-60 days after receive payment

shipment : by ocean vessles or by air freight

we send engineer to buyer factory to install the machine. in COVID time, we guide buyer install machine by videos on li

ne.

Our Machine Advantages

1. mechanical parts.

We use thick and strong raw material , machine frame very strong. All parts like bearing , shaft , we never use cheap brand. Our

machine total weight is higher 1-2 tons than other manufacturer same machine, because we use strong material .

2. electric parts

motor : best brand in our province, very big group company .

gear : from Guomao, best gear box manufacture of china

electric parts: OMRON, SIEMENS ABB. All are original parts, not copy. Some copy parts you can not recognize from the eyes.

Electric cabinet : 1.5mm thick material , and big .

3. our machine can use long time. For example, other manufacture machine can use 20 years, ours can use 25 years.

4. some material like steel made for water tank , we use 304 , never get rust . other manufacturer may use 201, it will get rust

after 3 month.

5. some parts, like die head, we do forging , some manufacturer don’t do. But you can not recognize from seeing just.

6. surface treatment . we spend a lots of time and works to do. Sanding , remove rust , 3 time painting .

if ours machine put together with other cheap machine, you will see very clear different . just from my description, its difficult

to say. Our customers mostly are returned customers or introduced customers, they know our machine well. So they come back again

to buy .

we considered all points for buyer

We use thick and strong raw material , machine frame very strong. All parts like bearing , shaft , we never use cheap brand. Our

machine total weight is higher 1-2 tons than other manufacturer same machine, because we use strong material .

2. electric parts

motor : best brand in our province, very big group company .

gear : from Guomao, best gear box manufacture of china

electric parts: OMRON, SIEMENS ABB. All are original parts, not copy. Some copy parts you can not recognize from the eyes.

Electric cabinet : 1.5mm thick material , and big .

3. our machine can use long time. For example, other manufacture machine can use 20 years, ours can use 25 years.

4. some material like steel made for water tank , we use 304 , never get rust . other manufacturer may use 201, it will get rust

after 3 month.

5. some parts, like die head, we do forging , some manufacturer don’t do. But you can not recognize from seeing just.

6. surface treatment . we spend a lots of time and works to do. Sanding , remove rust , 3 time painting .

if ours machine put together with other cheap machine, you will see very clear different . just from my description, its difficult

to say. Our customers mostly are returned customers or introduced customers, they know our machine well. So they come back again

to buy .

we considered all points for buyer

Hot Searches