- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

25400*3600*2200(mm)

-

Weight (KG):

-

60000

-

Power (kW):

-

1000

-

Warranty:

-

1 year

-

Spindle Speed:

-

2000

-

Diameter of hole honed:

-

40-140mm

-

Packing(L*W*H) mm:

-

12000x2000x6000

-

Model:

-

WXC20C

-

Precision:

-

0.01

-

Max Honing Depth:

-

6000

-

Certification:

-

Iso9001

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Haige

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

25400*3600*2200(mm)

-

Weight (KG):

-

60000

-

Power (kW):

-

1000

-

Warranty:

-

1 year

-

Spindle Speed:

-

2000

-

Diameter of hole honed:

-

40-140mm

-

Packing(L*W*H) mm:

-

12000x2000x6000

-

Model:

-

WXC20C

-

Precision:

-

0.01

-

Max Honing Depth:

-

6000

-

Certification:

-

Iso9001

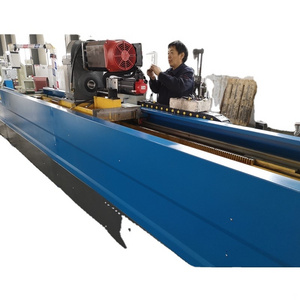

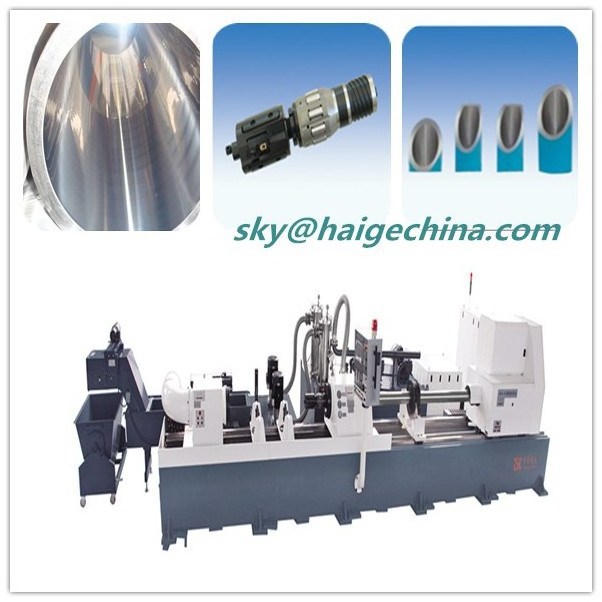

We can provide CNC Skiving & Roller Burnishing Machines with different configurations that can process work pieces with inner diameters from Ø 40 to Ø 250 and the lengths of 1.5m, 2m, 3m, 4m, 6m, 9m, and 10m, among others.

Field of Application

Contruction machinery, colliery hydraulic holder, colliery scaper conveyor, special usage truck, maritime ship, harbour machinery, petroleum machinery, mining machinery, water conservancy machinery etc.

|

Main Parameters |

||||

|

Model |

ZTG 2530 |

ZTG2560 |

ZTG 2590 |

|

|

Workpiece dimension |

Internal diameter(mm) |

Φ50-250

|

Φ80-250

|

Φ90-250

|

|

External diameter(mm) |

Φ60-300

|

Φ90-300

|

Φ100-300

|

|

|

Processing length(mm) |

500-3000 |

1200-3000 |

1650-9000 |

|

|

Speed |

Spindle speed(r/min) |

50-1500 |

||

|

Locating seat movement(mm/min) |

6000 |

|||

|

Spindle box movement(mm/min) |

8000 |

|||

|

Motor power |

Spindle servo(Kw) |

37/56 |

||

|

Feed servo(Kw) |

6 |

|||

|

Cooling system |

Oil tank capacity |

4150+1850 |

4150+1850 |

6000+1850 |

|

Pumping capacity |

> 500 |

> 500 |

> 700 |

|

|

Filter fineness |

50 |

|||

|

Total motor power |

90 |

100 |

||

|

Dimension |

12100*3600*2200 |

18820*3600*2200 |

25400*3600*2200 |

|

|

CNC system |

Spanish : FAGOR , Germany : SIEMENS |

|||

Advantages compared with traditional honing

1) Improve processing efficiency: Processing speed is nearly 20 times that of honing.

2) Enhance surface hardness: Surface hardness is increased by more than 50%.

3) Processing precision: Processing precision can reach level IT8, and surface roughness can reach Ra0.05-0.4 μ m.

4) Working environment: Low noise, non-pollution, labor cost-saving.

5) Reasonable processing arrangement: Skiving & roller burnishing can be arranged as the last operation after the others (such as drilling oil filler hole, welding, threading).

A. Warranty period: 1 year,except for fast-wearing parts

B. Reply your enquiry in 24 working hours

C.Customized design is available. OEM& ODM are welcomed.

D. If necessary,we can dispatch our well-trained and professional engineers to our customers' factory to help them install and debug the equipment.

E.Special discount can be provided to our distributor.