- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According to the customer

-

Weight:

-

58993 KG

-

Product name:

-

3000ton Seed Steel Grain Storage Silo Stocking Silo for Sale

-

WhatsApp:

-

+86 13598071775

-

Capacity:

-

100-10,000 T

-

Coating:

-

Galvanized 275-600g/m2

-

Safety inspection device:

-

Temperature and moisture monitoring systems

-

Usage:

-

Grain/Cereal/Feed/Pellet Storage

-

Silo Life:

-

25-40 Years

-

Monitoring System:

-

Temperature and Moisture Supervision SIMENS PLC, etc.

-

Handling equipment:

-

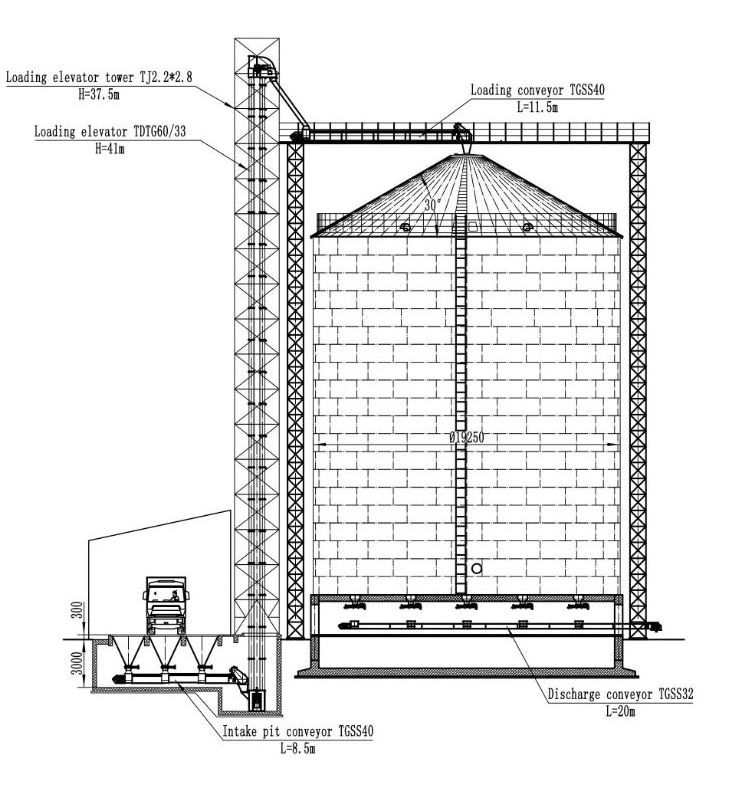

Bucket elevator, drag conveyor, belt conveyor, screw auger, etc.

Quick Details

-

Core Components:

-

Steel Plate

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HKB

-

Dimension(L*W*H):

-

According to the customer

-

Weight:

-

58993 KG

-

Product name:

-

3000ton Seed Steel Grain Storage Silo Stocking Silo for Sale

-

WhatsApp:

-

+86 13598071775

-

Capacity:

-

100-10,000 T

-

Coating:

-

Galvanized 275-600g/m2

-

Safety inspection device:

-

Temperature and moisture monitoring systems

-

Usage:

-

Grain/Cereal/Feed/Pellet Storage

-

Silo Life:

-

25-40 Years

-

Monitoring System:

-

Temperature and Moisture Supervision SIMENS PLC, etc.

-

Handling equipment:

-

Bucket elevator, drag conveyor, belt conveyor, screw auger, etc.

3000ton Seed Steel Grain Storage Silo Stocking Silo for SaleStorage Corn

1. HKB grain silo is specially designed by senior engineers in our company, with high-quality galvanizing board.

2. Hopper angles can be 45° and 60°, among which 60° conical bottom is usually used to store larger pellet and powder materials with high viscosity.

3. All silos are precision engineered from high strength, 80mm x 14mm low profile corrugated steel plate, normally galvanized to 275g/m2.

4. The life cycle of the silos can come up to 30-50 years long. The products are designed to comply with the national standard of GB50322-2001.

5. HKB silos provide the best quality grain storage option available. Erection of the most popular 250t, 500t, and 1,000t silos is straightforward, and can typically be completed in around 10 days per silo.

*Assembly, easy to ship and

save freight

.

*Hot-dip galvanized plates (275g/m2-600g/m2), very

WATERPROOF

&

RUST-PROOF

.

*Flat bottom has

large capacity

from 1500T-20000T.

*Silos can store grain safely and

save labor cost and space

.

| 3000Ton Flat Bottom Grain Silo Technical Parameter | |||||

| Model | Layer | V(m3) | C(t) | Diameter(m) | High(m) |

| TCK15518 | 18 | 4358 | 3268 | 21.35 | 25.90 |

| TCK16514 | 14 | 3707 | 2780 | 15.75 | 20.26 |

| TCK17414 | 14 | 4151 | 3113 | 15.75 | 20.51 |

| TCK18314 | 14 | 4623 | 3467 | 15.75 | 20.76 |

|

TCK19214 |

14 | 5123 | 3842 | 15.75 | 21.01 |

Provides assembly farm silo convering from 10t—10000t each. There are used for wheat, corn,plastic,plastic or any type of pellets, and also provies the silo for wheat/corn flour,cement ,sand or any type of powder.

Farm silos are made of hot dip galvanizing steel sheets with coating of 275g/m2, or 350g/m2, 400g/m2 etc. The silos can also be made of the carbon steel Q235 for the powder silo with painting mass. Made as per the Chinese national standard or Austrilian standard, American standard.

|

Silo Roof The special trapezoidal geometry of roof gives high strength and stiffness. The professional sealed technology enables tight connection of roof with the sidewall and keeps stored products from moisture. |

|

|

Silo Body The coaming of the silo is made of 275g/m2 galvanized steel plate. The coaming is gradually thicjened from top to bottom according to the stress of each layer. |

|

|

Access Ladder & Door

|

|

|

Concrete Silo Base

|

|

Optional Accessories

Starting from the initial project analysis, to develop your custom grain silo system plan and to the final turnkey completion of the project, HKB’s engineers will stand together with you to get the best matching profitable solution.

Henan Haokebang Machinery Equipment Co., Ltd. specializes in the production of 100-10,000 ton hopper bottom and flat bottom corrugated galvanized steel silos. According to various factors such as site, weather, and geology, we provide professional silo design, equipped with elevators, unloading pits, pre-cleaner, conveyors, sweeping auger and other accessories to meet the diverse needs of customers.

HKB’s own installation engineers team plays a respectable role in the success high-performance whole silo system. Our motivated team has rich installation experience for various types of silos, work under strict and standardized installation management system, thorough installation cross-checking rules, and they promise one-time project acceptance.

Henan Haokebang Machinery Equipment Co.,ltd. is a professional supplier of silos.

HKB have the agent now in Thailand, South Africa, Austrilia,Bangladesh, Israel. And

have been sold to more than 50 countries, such as Argentina, Chile, Cambodia, Ethiopia, Honduras, Indonesia, Korea, Malaysia, Myanmar, South Africa, Sudan, Serbia, Thailand, Tanzania, Ukraine, Vietnam, Peru, Korea, Philipine, Uganda and so on.

The real factory without any middle trading man to do the business with customer directly, Has the separate research & development, project engineering, manufacturing, sales, installation and services team.