- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

23m*2.3m*2.2m

-

Power (kW):

-

168KW

-

Weight (KG):

-

10000 KG

-

Max.forming area:

-

1100*1380mm

-

Max.forming depth:

-

80mm

-

Keyword:

-

ps foam food box machine

-

material:

-

polystyrene sheet

-

Machine name:

-

disposable lunch tray plate dish vacuum forming machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Finished products:

-

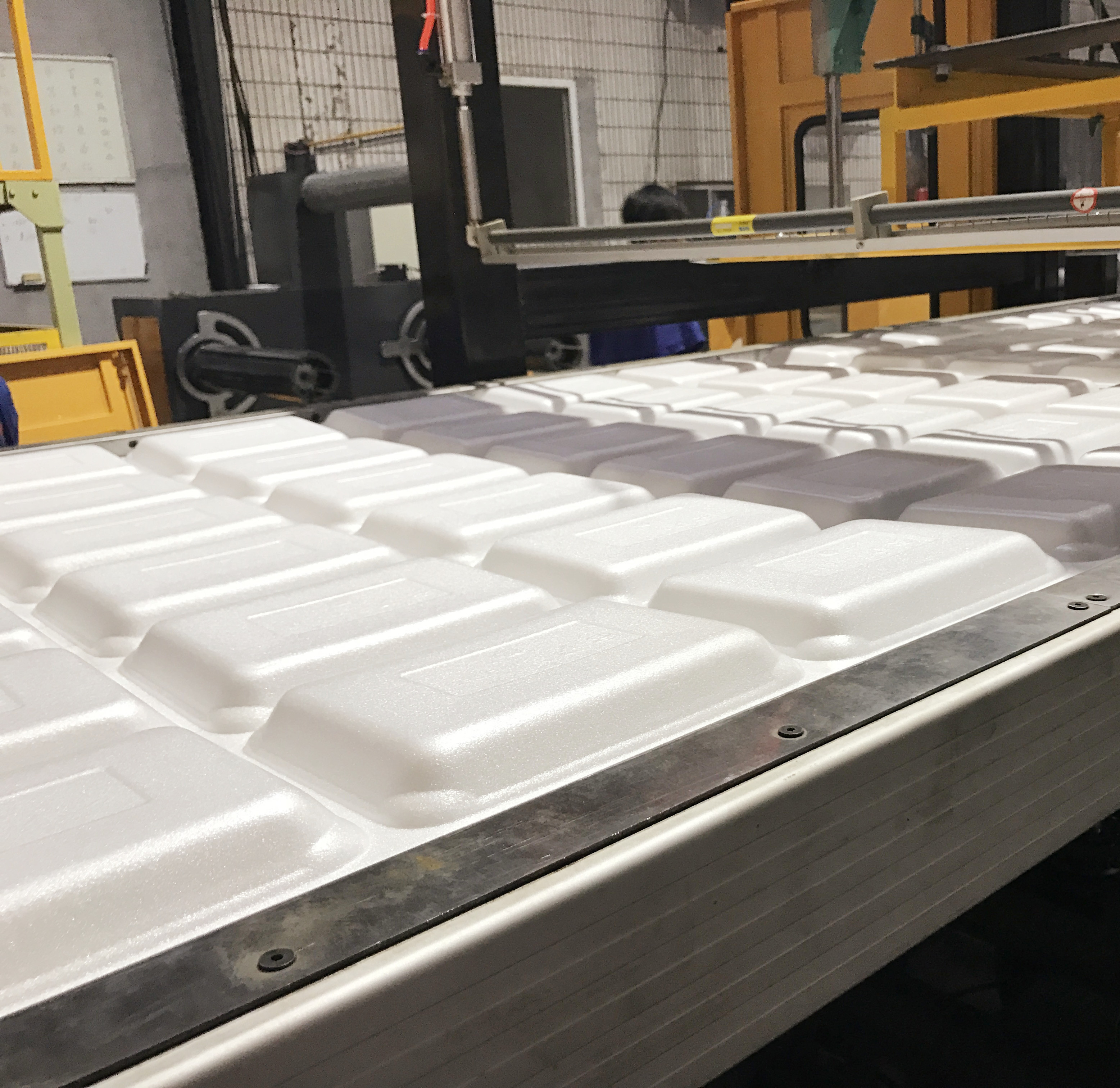

disposable fast food box plate tray dish

-

Advantage:

-

competitive price

-

production efficiency:

-

3-5s/mold

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

ps foam machine

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

23m*2.3m*2.2m

-

Power (kW):

-

168KW

-

Weight (KG):

-

10000 KG

-

Max.forming area:

-

1100*1380mm

-

Max.forming depth:

-

80mm

-

Keyword:

-

ps foam food box machine

-

material:

-

polystyrene sheet

-

Machine name:

-

disposable lunch tray plate dish vacuum forming machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Finished products:

-

disposable fast food box plate tray dish

-

Advantage:

-

competitive price

-

production efficiency:

-

3-5s/mold

LONGKOU DEYI MACHINERY COMPANY

supplies

PP, PET, PLA

, paper pulp and

PS foam take out food container machinery

, the following is different material machines for your reference, if you are interested in our machine, please contact us at any time, we are always be here.

PET thermoforming machine

three station and four station available

PP cup/box thermoforming machine

making plastic cup and box etc.

Biodegradable plastic tableware machine

make cup, box,tray and dish etc.

PS foam food box machine

make foam box, dish, egg tray, plate,container etc.

Paper take out box machine

hamburger boxes, square boxes, and food boxes

Sugarcane and paper pulp moulding machine

make paper pulp box, cup,and dish etc.

Product Description

Specification

Food Foam Container Machine

Forming cutting, stacking are done in the same machine, saving labor, improving efficiency, lowing labor intensity and reducing production cost. Production process is to put foam sheet into forming machine, and product and wastage will come out from the rear part. Two workers are enough for the whole production line.

polystyrene foam food container production line

It can be used to produce many kinds of materials. Product can be used in the food, medicine, electronic parts,tourism, toys, etc.

polystyrene foam food container production line

It can be used to produce many kinds of materials. Product can be used in the food, medicine, electronic parts,tourism, toys, etc.

|

MODEL

|

UNIT

|

DY-1040

|

DY-1380

|

|

max.forming area

|

mm

|

1000*1100

|

1100*1380

|

|

max.forming depth

|

mm

|

80

|

100

|

|

production efficiency

|

s/mould

|

43529

|

43529

|

|

forming pressure

|

T

|

15

|

15

|

|

heating power

|

KW

|

108

|

142

|

|

total power

|

KW

|

168

|

204

|

|

total weight

|

T

|

15

|

16

|

PLA degradable tableware production line

The whole line includes three sets of machine:

1.PLA, PP, Corn Starch, talcum powder mixing machine

2.Granule machine

3.One-step tableware forming machine

One-step tableware forming machine will make the finished granules form tableware through heating, This machine is the latest core product developed by our company, integrated, punching, cutting, and stacking. It has a wide range of uses and is suitable for most customers' requirements. It can produce bowls, plates, various fast food boxes, packing boxes, supermarket trays, moon cake boxes, tofu boxes, biscuit boxes, etc. Stable operation, low noise, high efficiency and good quality.

2.Granule machine

3.One-step tableware forming machine

One-step tableware forming machine will make the finished granules form tableware through heating, This machine is the latest core product developed by our company, integrated, punching, cutting, and stacking. It has a wide range of uses and is suitable for most customers' requirements. It can produce bowls, plates, various fast food boxes, packing boxes, supermarket trays, moon cake boxes, tofu boxes, biscuit boxes, etc. Stable operation, low noise, high efficiency and good quality.

|

Item

|

Unit

|

Value

|

|

Screw 1

|

mm

|

90

|

|

Screw 2

|

mm

|

80

|

|

Screw 3

|

mm

|

65

|

|

Extrusion capacity

|

kg/h

|

270-320

|

|

Mold size

|

mm

|

250-780

|

|

Equipment size

|

mm

|

7500*2000*2000

|

|

Machine weigh

|

ton

|

7

|

PET PP Thermoforming Machine

PP PET thermoforming lunch box cup machine

PET PP Plastic Thermoforming Machine is forming, cutting and stacking in one line. It is completely driven by servo motor, stable operation, low noise, high efficiency, suitable for producing plastic trays, containers, boxes, lids, etc.

|

Forming area

|

750×850mm

|

|

Forming depth

|

100mm

|

|

Thickness range of sheet

|

0.1-2mm

|

|

Sheet roller diameter

|

710mm

|

|

Speed

|

400-720 moulds/h

|

|

Weight

|

11000kg

|

|

Dimension(L×W×H)

|

12000×2200×2200(mm)

|

Packing & Delivery

Hot Searches