- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Depends on the model

-

Weight:

-

1600 KG

-

Product name:

-

WEILIANG WLT Rectangular Wet Screen

-

Model:

-

WLT-12-4

-

Motor Power:

-

1.2KW*2, 0.45KW*1

-

Screen Material:

-

Stainless steel Screen/ Polyurethane Screen

-

Screen area(㎡):

-

2.7

-

Screen Quantity:

-

4 (one desk)

-

Operational Mode:

-

Linear Motion/ Elliptical Motion

-

Function:

-

Dewatering/ Degritting/ Desliming/Rinsing/Scrubbing

-

Certification:

-

ISO; CE

Quick Details

-

Type:

-

LINEAR

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Weiliang

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Depends on the model

-

Weight:

-

1600 KG

-

Product name:

-

WEILIANG WLT Rectangular Wet Screen

-

Model:

-

WLT-12-4

-

Motor Power:

-

1.2KW*2, 0.45KW*1

-

Screen Material:

-

Stainless steel Screen/ Polyurethane Screen

-

Screen area(㎡):

-

2.7

-

Screen Quantity:

-

4 (one desk)

-

Operational Mode:

-

Linear Motion/ Elliptical Motion

-

Function:

-

Dewatering/ Degritting/ Desliming/Rinsing/Scrubbing

-

Certification:

-

ISO; CE

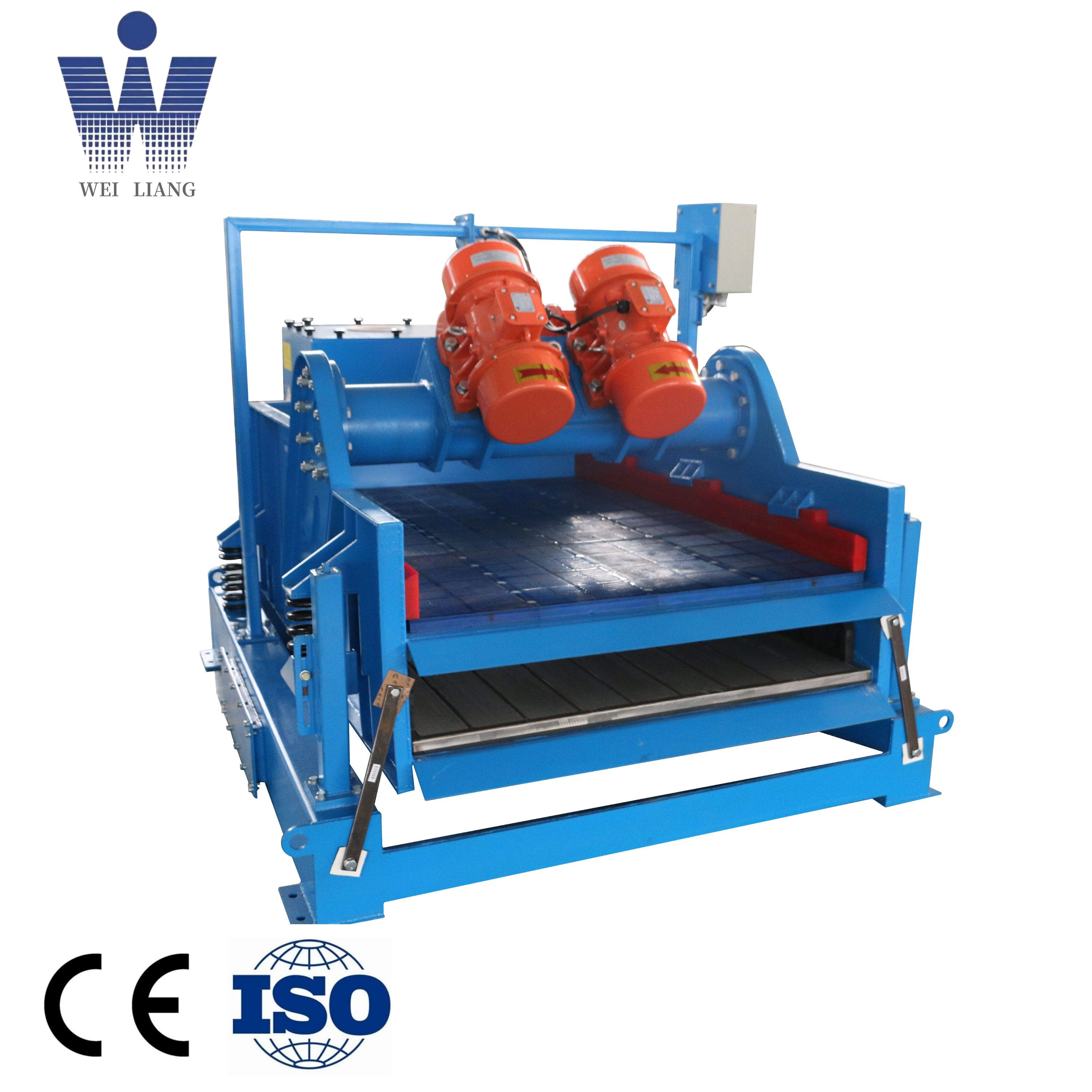

Product Description

WEILIANG WLT Rectangular Wet Screen

WEILIANG WLT Rectangular Wet Screen is usually used for

wet fine screening

and has a wide range of applications, including

dewatering, degritting, desliming, rinsing, scrubbing,

etc. The machines are designed to

dewater the slurries to a drip-free state with surface moisture content of between 15-20%

, which can be conveyed and stacked. They handle any material that is wet but need larger capacity, such as frac sand, kaolin, ceramic, paper fibers, precious metal ores, coal, iron ore, salt and other granular materials.

Details and Advantages

Principle of WLT Rectangular Wet Screen

The material is usually fed in the form of slurry. On an inclined rectangular wet screen, the material is forced towards the

discharge end due to acceleration and partial gravity, while the water is screened out by the appropriate screening media.

* Linear motion for fast conveying and heavy loading.

* Elliptical motion for maximum retention time and drier solids.

*

Multi-motion

. Combines linear and elliptical motion technology that delivers the benefits of two distinct motions.

* Control box switching modes simply and conveniently.

* Precise bed angle adjustment (-3° to +3°) ensures that the material on the screen flows evenly.

* Screen material can be changed according to different material characteristics and screening conditions, polyurethane screen or stainless steel screen.

* large capacity and high throughout.

* Excellent water removal , drier material surface.

* Simple construction and easy maintenance .

* Durable and long service life.

* Control box switching modes simply and conveniently.

* Precise bed angle adjustment (-3° to +3°) ensures that the material on the screen flows evenly.

* Screen material can be changed according to different material characteristics and screening conditions, polyurethane screen or stainless steel screen.

* large capacity and high throughout.

* Excellent water removal , drier material surface.

* Simple construction and easy maintenance .

* Durable and long service life.

Technical Parameters

Applications

* Screening Sand

* Sand recovery

* Scalping oversize from slurries

* Dewatering mineral concentrates

* Dewatering tailings

* Dewatering sand

* De-sliming

* Sand recovery

* Scalping oversize from slurries

* Dewatering mineral concentrates

* Dewatering tailings

* Dewatering sand

* De-sliming

It is used in petroleum drilling, metallurgy, building materials, chemical, food, ceramics, cement and other industries.

Packing & Delivery

Inner packaging: Stretch film for machine

Outer packaging: Standard export wooden box

Hot Searches