- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

zhengzhou, henan

-

Brand Name:

-

superb

-

Voltage:

-

380v

-

Weight:

-

850 KG

-

Dimension(L*W*H):

-

1950*1100*1180mm

-

Raw material:

-

Charcoal Powder

-

Fuel:

-

Electic

-

Briquette Shape:

-

Cuotomized

-

Color:

-

Customers' Requirement

-

Capacity:

-

1-2t/h

-

Kw:

-

7.5/11

-

Packing:

-

Wooden Box Packing

-

Certification:

-

ISO

-

Power:

-

11kw

-

Model Number:

-

sjcj140

Quick Details

-

Warranty:

-

1 Year

-

Marketing Type:

-

Hot Product 2023

-

Core Components:

-

spiral blade beat, reducer, forming cylinder

-

Place of Origin:

-

zhengzhou, henan

-

Brand Name:

-

superb

-

Voltage:

-

380v

-

Weight:

-

850 KG

-

Dimension(L*W*H):

-

1950*1100*1180mm

-

Raw material:

-

Charcoal Powder

-

Fuel:

-

Electic

-

Briquette Shape:

-

Cuotomized

-

Color:

-

Customers' Requirement

-

Capacity:

-

1-2t/h

-

Kw:

-

7.5/11

-

Packing:

-

Wooden Box Packing

-

Certification:

-

ISO

-

Power:

-

11kw

-

Model Number:

-

sjcj140

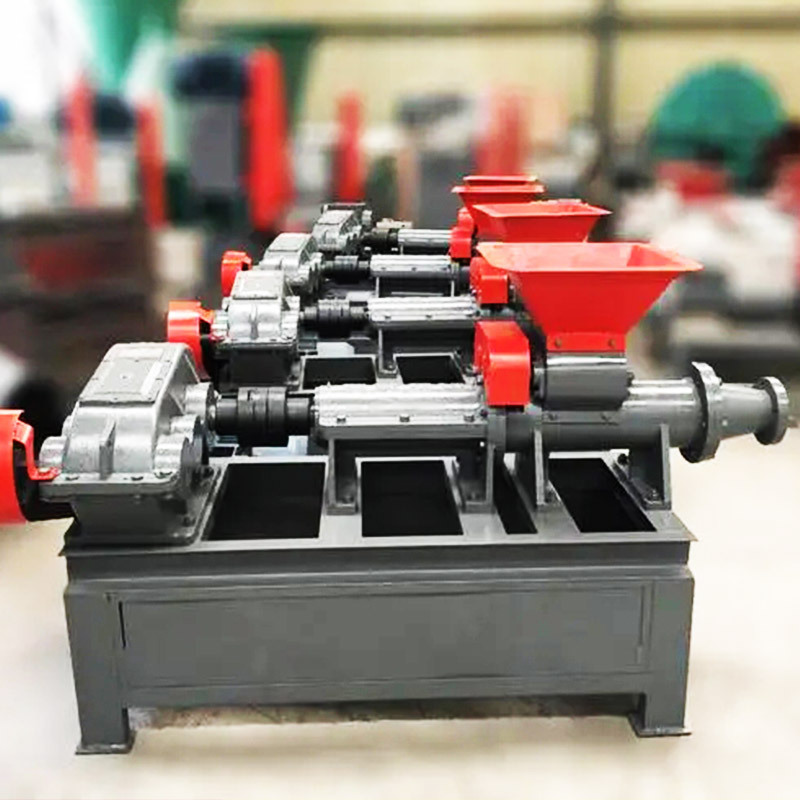

Display of Charcoal Briquette Machine

coal charcoal dust briket extruder machine

Features

* Charcoal extruder is a kind of machine that can make use of waste, recycle material and turn waste into wealth. It is low cost and durable to use.

* The service life of main wearing parts is prolonged from 40hours to 4000hours.

* The power cost is decreased 60%.

* The productivity is improved 2-3 times to 5-6t/h.

* The production cost is cut down about $33 (in China; in other places this may be different).

* The operation is much easier.

* It turns low quality charcoal into high quality charcoal.

* The service life of main wearing parts is prolonged from 40hours to 4000hours.

* The power cost is decreased 60%.

* The productivity is improved 2-3 times to 5-6t/h.

* The production cost is cut down about $33 (in China; in other places this may be different).

* The operation is much easier.

* It turns low quality charcoal into high quality charcoal.

Parameter of coal briquette machine

|

Model

|

Power(kw)

|

Capacity(t/h)

|

Weight(t)

|

Dimension(mm)

|

|

SJCJ140

|

7.5

|

1-2

|

0.85

|

1950*1100*1180

|

|

SJCJ180

|

22

|

2-3

|

1.2

|

2320*1580*890

|

Structure of charcoal briqutte extruder

The main structure of the coal stick machine is composed of a motor, a reducer, a screw propeller shaft, a mold, and the final cutter.

We provide customers with a large number of different molds to choose from, and we can also customize them according to customer needs.

Besides, we offer customers with three different cutting methods, as follows:

Pneumatic Cutting Device

This kind of pneumatic cutting machine is generally equipped at the exit of the charcoal briquette machine and equipped with an induction device. When the coal rod reaches a certain length, it will automatically cut.

Cubic charcoal cutting machine

This cubic cutting device is used to cut cubic coal. The cut coal rods pass through this machine to become coal blocks of uniform shape and size.

CNC cutting device

This is our latest coal cutting machine. It adopts an intelligent control system, the cutting length of coal rods can be adjusted freely and can be used to cut coal rods of various shapes.

What shapes of BBQ charcoal can be made?

The BBQ charcoal can be made into stick, ball or tablet shapes. But stick shape charcoal is most often used for BBQ.

How To Make Sticks With Charcoal Extruder?

Step 1: Raw material collection

you need to have enough raw materials for BBQ charcoal making, and the raw material biomass must be easy to access. So it is strongly advised to set up the charcoal making plant near your raw material in order to save transportation cost.

Step 2: Carbonization

put the biomass raw material in a kiln and ignite the biomass, then seal the kiln to let the raw material carbonize. And charcoal is produced.

Step 3: Charcoal crushing

crush the charcoal into powder.

Step 4: Charcoal powder mixing

mix the charcoal powder with binder. Binder is used to adhere the charcoal powder.

Step 5: BBQ charcoal extruding:

feed the charcoal powder into the BBQ charcoal extruder, and charcoal sticks are extruded.

Step 6: Charcoal sticks drying and packing

cool and dry the charcoal sticks, then pack them for sale.

Customer Cases of Charcoal Powder Extruder

A customer from E cuador ordered a briquettes extruder machine with a capacity of 500kg/h. This customer mainly uses this machine to produce square charcoal briquettes.

The raw material is coconut shell.

Packing and Delivery

We respect the contract, and will deliver the goods on time as agreed for customized order. For normal products, we have stocks for immediate delivery.

Contact us

Hot Searches