- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Traditional

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LUX

-

Model Number:

-

LUX-TBB

-

Type:

-

XPS Board

-

Material:

-

XPS, fiberglass mesh & cement

-

Color:

-

Blue XPS foam, grey coating

-

Size:

-

Normal size and accept customization

-

Compress Strength:

-

300Kpa/CBM

-

Density:

-

32±0.02KG/SQM

-

Working Life:

-

10 years quality guarantee

Quick Details

-

Warranty:

-

5 years

-

After-sale Service:

-

Online technical support, Free spare parts

-

Project Solution Capability:

-

Others

-

Application:

-

Hotel

-

Design Style:

-

Traditional

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LUX

-

Model Number:

-

LUX-TBB

-

Type:

-

XPS Board

-

Material:

-

XPS, fiberglass mesh & cement

-

Color:

-

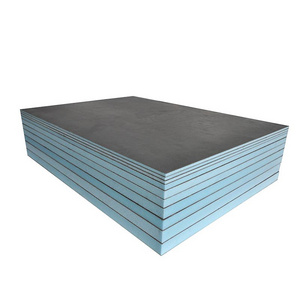

Blue XPS foam, grey coating

-

Size:

-

Normal size and accept customization

-

Compress Strength:

-

300Kpa/CBM

-

Density:

-

32±0.02KG/SQM

-

Working Life:

-

10 years quality guarantee

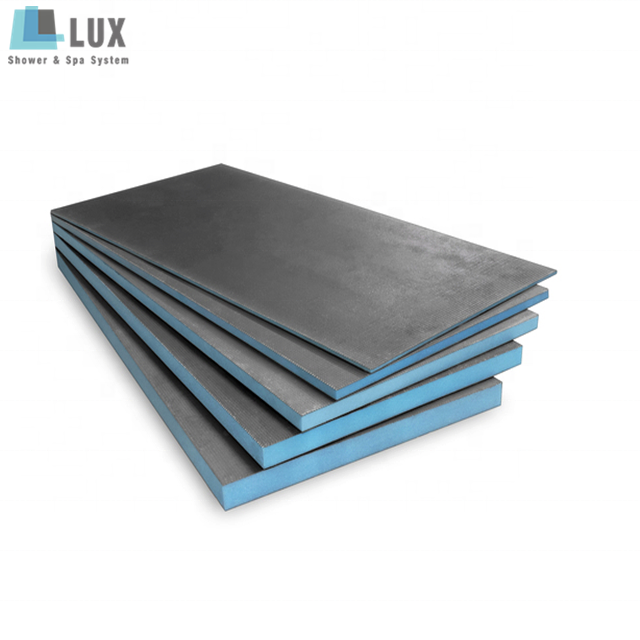

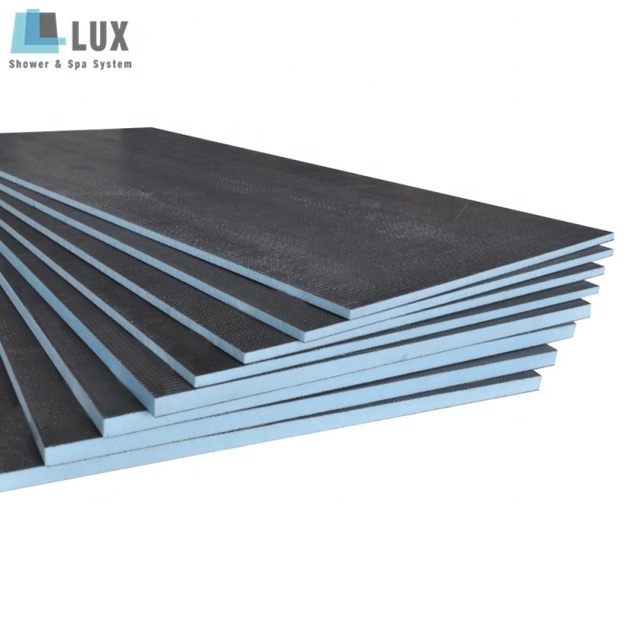

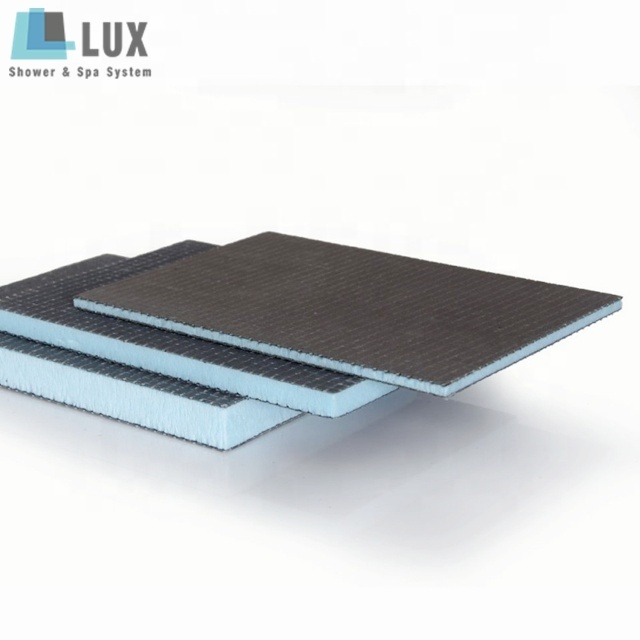

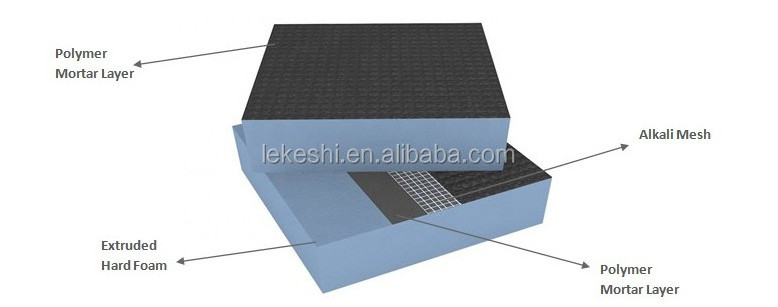

LUX XPS Tile Backer Board is the innovative alternatives to traditional cement backers. It's HCFC-free waterproof XPS core, fiberglass reinforced and cement coating gives the panel strength and vapor retardant. Making LUX panel is perfect choice for a variety of interior and exterior applications, such as the inter layer to wall or floor and thermal insulation board in underfloor heating system.

|

Product Name

|

High density extruded polystyrene flexible sheets styrofoam board 6mm 10mm 12mm

|

|

Composition

|

XPS core, Alkali Mesh, Polymer Mortar Layer

|

|

Color

|

Blue XPS foam, grey coating

|

|

Quality

|

Grade A

|

|

MOQ

|

100 PIECE

|

|

Loading Port

|

NINGBO

|

|

Payment Term

|

T/T 30% deposit, balance to be paid before shipment

|

|

Delivery time

|

25-30 days after receiving 30% deposit

|

|

Characteristics

|

Eco-saving, lightweight, moisture-proof, easy construction, acid resistance.

|

|

Quality sample

|

Offer free sample on your courier account (DHL.UPS.TNT.FEDEX.ECT)

|

|

Usage

|

Wet areas, shower room, underfloor heating, etc.

|

Hangzhou LUX New Material Tech Co,Ltd. Was founded in 2018, has been the Chinese leading manufacture and innovator of thermal insulation and waterproof industry.

LUX offer architects, builders and tile contractors a durable, lightweight, waterproof and vapor retardant tile backer board for wet room and underfloor heating system.

With its timely delivery, high-quality product and best service.

LUX has got a global reputation, we thank you for considering LUX products for interior project and and renovation.

Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Team

Our Team

Packing Details : Packing with paper carton and pallet

Delivery Details : 25-30 days after order of Solid bicycle tire tubes

Q: Why do I need LUX BOARD?

A: Because LUX BOARD will save you money by acting as a very efficient insulation barrier. It reflects the heat upwards into the floor tile instead of allowing the heat to warm up the concrete slab below. Besedes, it not only has the function of heat insulation and strong waterproofness, but also provides a base for the ceramic tile.

Q: How does compare to plasterboard?

A: It doesn't there really is no comparison. Standard plasterboard offers approximately 1/6th the U value of an equal thickness of LUX BOARD. and yet is approximately 7 times heavier. When used in wet areas, such as bathrooms or showers. LUX BOARD is totally waterproof whereas plasterboard will absorb water unless it is of the waterproof variety which will cost considerably more.

Compare a few characteristics of LUX BOARD against plasterboard:1. 1/7th the weight of Plasterboard

2. waterproof, ordinary plasterboard is not.

3. (10mm) has a U value of 2.7 against 12.8 W/M2 K of 12.5mm

Q: How do I fix LUX BOARD to walls?

A: The board can be either fixed to timber battens with screws and screw cups or fixed directly to brick or block walls by drilling, plugging and screwing the boards to the wall. If the wall is to be plaster finished, the joints should be reinforced with a plaster scrim.

Q: Where else could I use LUX BOARD?

A:

It can be used on walls, ceilings and floors in bathrooms, kitchens, garages, lofts, and conservatories to name a few. In fact the list is endless.