- Product Details

- {{item.text}}

Quick Details

-

MF:

-

K2O, Na2O, Al2O3

-

EINECS No.:

-

1318-02-1

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Xintao

-

Model Number:

-

3A Molecular Sieve

-

Product name:

-

Zeolite molecular sieve 3a price

-

Color:

-

Light Gray

-

Shape:

-

Sphere ,Pellet

-

Diameter:

-

1.7-2.5;3.0-5.0;1.6;3.2

-

Size Ratio up to grade(%):

-

≥98

-

Bulk Density(kg/m3):

-

680-750kg/m3

-

Crushing Strength(N):

-

30-100N/piece

-

Static H2O Adsorption(%):

-

≥21

-

Ethylene adsorption:

-

≤3

-

Sample:

-

For free

Quick Details

-

CAS No.:

-

1318-02-1

-

Purity:

-

99.9%

-

Other Names:

-

Zeolite

-

MF:

-

K2O, Na2O, Al2O3

-

EINECS No.:

-

1318-02-1

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Xintao

-

Model Number:

-

3A Molecular Sieve

-

Product name:

-

Zeolite molecular sieve 3a price

-

Color:

-

Light Gray

-

Shape:

-

Sphere ,Pellet

-

Diameter:

-

1.7-2.5;3.0-5.0;1.6;3.2

-

Size Ratio up to grade(%):

-

≥98

-

Bulk Density(kg/m3):

-

680-750kg/m3

-

Crushing Strength(N):

-

30-100N/piece

-

Static H2O Adsorption(%):

-

≥21

-

Ethylene adsorption:

-

≤3

-

Sample:

-

For free

sphere 1.7-2.5 mm zeolite molecular sieve 3a desiccant for liquid alcohol dehydration

Technical Data Sheet

| Model | 3A | |||

| Color | Light gray | |||

| Nominal pore diameter | 3 angstroms | |||

| Shape | Sphere | Pellet | ||

| Diameter (mm) | 1.7-2.5 (8*12mesh) | 3.0-5.0 (4*8mesh) | 1.6 (1/16 inch) | 3.2 (1/8 inch) |

| Size ratio up to grade(%) | ≥98 | ≥98 | ≥96 | ≥96 |

| Bulk density (g/ml) | ≥0.70 | ≥0.70 | ≥0.68 | ≥0. 68 |

| Wear ratio (%) | ≤0.20 | ≤0.20 | ≤0.40 | ≤0.40 |

| Crushing strength (N) | ≥35/piece | ≥85/piece | ≥30/piece | ≥50/piece |

| Static H2O adsorption(%) | ≥21 | ≥21 | ≥21 | ≥21 |

| Dynamic capacity (%) | ≥20 | ≥20 | ≥20 | ≥20 |

| Ethylene adsorption (‰) |

≤3.0

|

≤3.0

|

≤3.0

|

≤3.0

|

| Water content (%) |

≤1.5

|

≤1.5

|

≤1.5

|

≤1.5

|

| Typical Chemical Formula | 0.4K2O . 0.6Na2O . Al2O3 . 2SiO2 . 4.5 H2O (SiO2 : Al2O3 ≈2) | |||

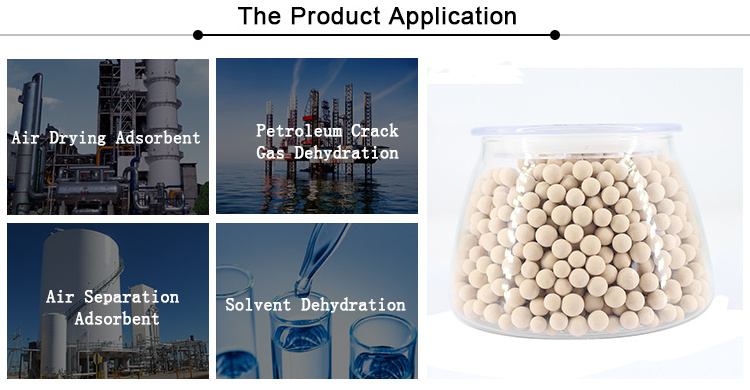

| Typical Application |

a) Drying of unsaturated hydrocarbons (e.g. ethylene, propylene, butadien)

b) Cracked Gas Drying c) Drying of natural gas, if COS minimization is essential, or a minimum co-adsorption of hydrocarbons is required. d) Drying of highly polar compounds, such as methanol and ethanol e) Drying of liquid alcohol. f) Static, (non-regenerative) dehydration of insulating glass units, whether air filled or gas-filled. g) Drying of CNG. |

|||

| Warranty: |

a) By National Standard GBT 10504-2008 b) Offer lifetime consultation on problems occurred |

|||

3A molecular sieve have the characters of higher adsorption speed, stronger crushing and anti-contaminative resistance, more cyclic times and longer work-span. All these advantages have made it come to be the most essential and necessary desiccant in the fields of the deep drying, refinery polymerization for cracked gasses, ethylene, propylene and any other non-acidic gasses of liquids in petroleum and chemical industrials.