- Product Details

- {{item.text}}

Quick Details

-

Welding Mode:

-

MIG MAG SAW TIG

-

Welding Diameter:

-

<2000mm

-

Dimensions:

-

2200*1500*1800mm or as design

-

Usage:

-

automatic weld fuel tank

-

Voltage:

-

380V

-

Weight (KG):

-

2000 KG

-

Power (kW):

-

20~30kw

-

welding seam type:

-

square seam /circumference/circular/ longitudinal/Surfacing/spiral

-

Function:

-

Automatic weld fuel tank cup

-

Color:

-

Blue or as required

-

Technology:

-

CNC,PLC

-

Application:

-

Solar Water Heater fuel gas LPG Tank

-

Wire diameter:

-

1.0mm-1.2mm

-

Welding material:

-

Carbon Steel Stainless Steel Aluminum,cast iron

-

OEM/customized:

-

Accept

-

protection shield:

-

add or not as required

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

India

-

After-sales Service Provided:

-

Field maintenance and repair service, Online support, Video technical support

-

Certification:

-

ISO CE BV

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAOYU

-

Forming Time:

-

2015

-

Welding Mode:

-

MIG MAG SAW TIG

-

Welding Diameter:

-

<2000mm

-

Dimensions:

-

2200*1500*1800mm or as design

-

Usage:

-

automatic weld fuel tank

-

Voltage:

-

380V

-

Weight (KG):

-

2000 KG

-

Power (kW):

-

20~30kw

-

welding seam type:

-

square seam /circumference/circular/ longitudinal/Surfacing/spiral

-

Function:

-

Automatic weld fuel tank cup

-

Color:

-

Blue or as required

-

Technology:

-

CNC,PLC

-

Application:

-

Solar Water Heater fuel gas LPG Tank

-

Wire diameter:

-

1.0mm-1.2mm

-

Welding material:

-

Carbon Steel Stainless Steel Aluminum,cast iron

-

OEM/customized:

-

Accept

-

protection shield:

-

add or not as required

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

India

-

After-sales Service Provided:

-

Field maintenance and repair service, Online support, Video technical support

-

Certification:

-

ISO CE BV

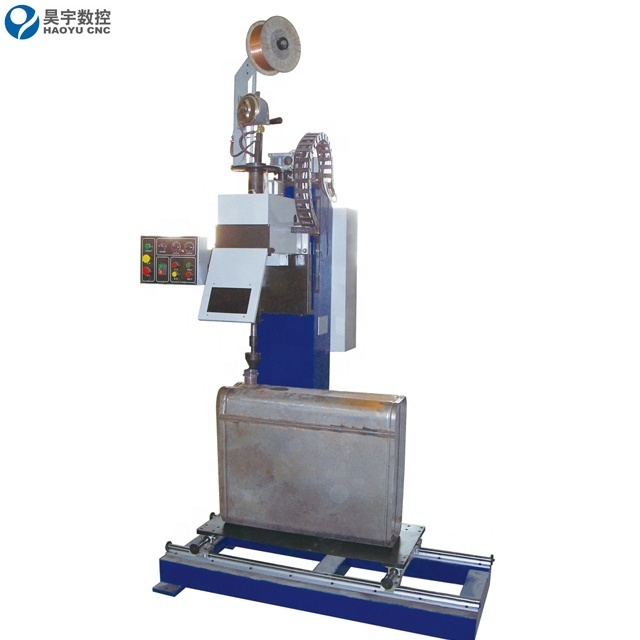

CNC automatic mig weld aluminum fuel tank fuel tank head welding machine circular seam welding machine

I.Machine functions

1. Automatic weld double square seams between the square fuel tank and two end cap as customers’ drawing (also can weld the same size range of Round tank )

2.MIG pulse welding with wire feeder or Tig welding machine with automatic wire filling mechanism.

3.For the square welding seam, its welding seam is irregular,so use CNC control the welding torch to walk the welding seam path .equip ped with the Electric minute adjust system to adjus t the welding torch during welding to solve the Non-standard docking caused by non-standard workpiece size or improper assembly.Meanwhile, it should guarantee that the welding specification is as even and uniform as possible.

4 . Welding Torch and tail stock can be adjusted longitudinally to fit various kinds of size fuel tank welding.

5 .Welding process will be continual and steady. Welding seam appearance is good and smooth, the depth of fusion and width of fusion meet the welding requirement, leakage rate is less than 1%

6 .Adopt heavy duty welded machine body, Workpiece is positioned by chuck and pressed by pneumatic Moths Morse taper,Rotating synchronously.convenient and quick for centering, good concentricity, and small deformation.

7 .During the welding,the workpiece is rotate ,and the welding torch is fixed.Workpiece rotation speed is adjusted by servo motor , stepless adjustment, to improve the reliability.

8 . The machine equipped with the function of high voltage, slow wire feeding and arc ignition to ensure reliable arc ignition, as well as low voltage and low current arc closing and arc crater filling functions.

9

.The welding power source has excellent performance of arc igniting, arc stabilization and arc ending, to ensure uniform welding seam, short-distance push-wire feeder is to ensure the wire feeding stability.

can achieve a stable pulse-by-drop transition under any welding current conditions through the welding expert parameters set in the digital power supply, so as to obtain a uniformly formed and beautiful weld.

II

Main configuration

Introduction

1. Equipment consists of machine body , fixture, rot ary axis power mechanism, workpiece vertical C NC t ravelling mechanism, forward and backward C NC t ravelling mechanism, welding torch adjustment mechanism, CNC control system, electrical control system, welding power source and other components .

|

Applicable diameter |

max1000 mm |

|

Applicable length |

max 3000mm |

|

Material |

s tainless steel; S teel,Al,copper or other metal |

|

Thickness |

>0.8 mm |

|

Rotation speed |

0.2-2rpm |

|

Motor power |

0.55KW |

|

Welding torch moving range in left-right direction |

100mm |

|

Welding torch lifting range |

100mm |

|

welding torch moving range in front-rear direction |

50mm |

|

Welding power source |

Miller or lincoln or fronius or Kemppi or Japan OTC or China Aotai or as customers required |

|

Machine working voltage |

220V single phase 50hz for machine 380v 3phase 50hz for welding power source |