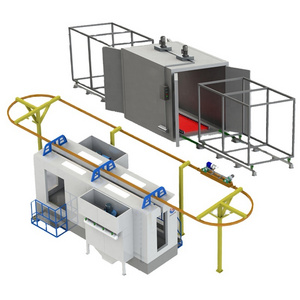

The automatic powder coating line

can be used for all metal industries such as Aluminum tubes, Steel pipes, Gates, Fire Boxes, Valves, Cabinets, lampposts, bikes and etc.

The line can be customized according to the product's size and weight.We have lots of patents: such as wind curtain, quick color change and circle design of powder coating booth to reduce the dust.

How to design an optimal solution for the powder coating line ?

1. Comprehensive analysis of customer cost budget and capacity requirements, select manual delivery mode;

2. Delivery method: Manual &A

utomatic

3. Comprehensive analysis of workpiece weight, size, shape and other factors, select the ground rail mode and design the

optimal running length;a

We design the power coating solution a

ccording to your

requirement

Design the whole line to cover less workshop space.

Make sure the best running of the whole line with the workpiece and easier operations of workers.

High quality materials with professional design and productions.

The line will be assembled and tested before delivery ( clients will be warmly welcomed to visit and inspect the quality and operations at any time) 3D assemble drawings will be sent to help clients do assemble works very easy and efficient.

Make arrangements in advance to make sure the products be delivered in time.

Use space mostly, easier operations, high working efficiency, low noise, environmental friendly.

All details should be made based on the details clients supplied and confirmed;

Our Clients:

Many projects finished all over the world, including China, Europe (UK, Ireland, Switzerland, Bulgaria, Cyprus,

Croatia); Australia, New Zealand, Middle East (Qatar, Kuwait); Southeast Asia (Thailand, Philippines); Latin America (Mexico,Chile, Ecuador); Africa (Morocco, Nigeria), and so on.