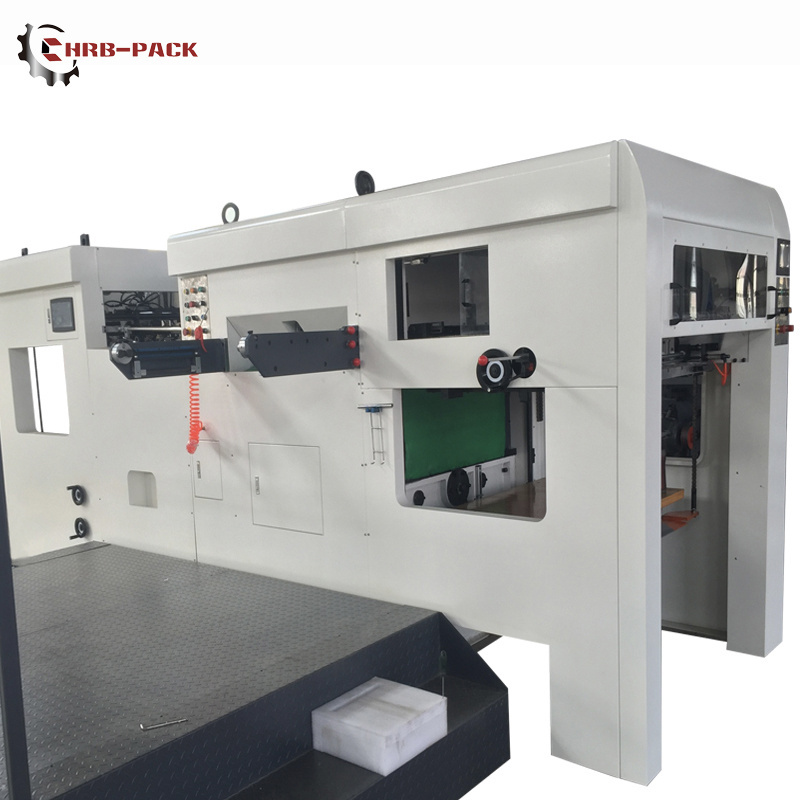

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hairuibao

-

Voltage:

-

220V 380V 440V

-

Dimension(L*W*H):

-

7690mm*3800mm*2330mm

-

Weight:

-

16000 kg

-

PLC Brand:

-

custom

-

Product name:

-

Automatic flat bed creasing and die cutting machine

-

Brand:

-

Hairuibao

-

Max. paper size:

-

1060mmx760mm

-

Min. paper size:

-

400mmx370mm

-

Max. die cutting size:

-

1050mmx750mm

-

Paper thickness:

-

paperboard:0.12-2.0mm corrugated paper:≤4mm

-

paper feeding height:

-

1500mm

-

Paper delivering height:

-

1220mm

-

Die cutting precise:

-

≤±0.10mm

-

Min. gripper:

-

Min. Gripper:7mm Max. Gripper:12mm

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

Other

-

Max. workable width:

-

Other

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hairuibao

-

Voltage:

-

220V 380V 440V

-

Dimension(L*W*H):

-

7690mm*3800mm*2330mm

-

Weight:

-

16000 kg

-

PLC Brand:

-

custom

-

Product name:

-

Automatic flat bed creasing and die cutting machine

-

Brand:

-

Hairuibao

-

Max. paper size:

-

1060mmx760mm

-

Min. paper size:

-

400mmx370mm

-

Max. die cutting size:

-

1050mmx750mm

-

Paper thickness:

-

paperboard:0.12-2.0mm corrugated paper:≤4mm

-

paper feeding height:

-

1500mm

-

Paper delivering height:

-

1220mm

-

Die cutting precise:

-

≤±0.10mm

-

Min. gripper:

-

Min. Gripper:7mm Max. Gripper:12mm

| Model | HRB-1300 | HRB-1500 |

| Max. Paper size | 1300 x 950 mm | 1300 x 950 mm |

| Min. Paper size |

550 x 500 mm |

550 x 500 mm |

| Max. Die cutting presure | 300N/CM ² | 300N/CM ² |

| Speed | 4500sheets/h | 4500 sheets/h |

| Max. Feeding pile height | 1400mm | 1400mm |

| Max. Delivery pile height | 1200mm | 1200mm |

| Power | 13.5 KW | 13.5 KWR |

| Weight | 14.5T | 16T |

| Size | 4000x2250x2250mm | 4200x2300x2250mm |

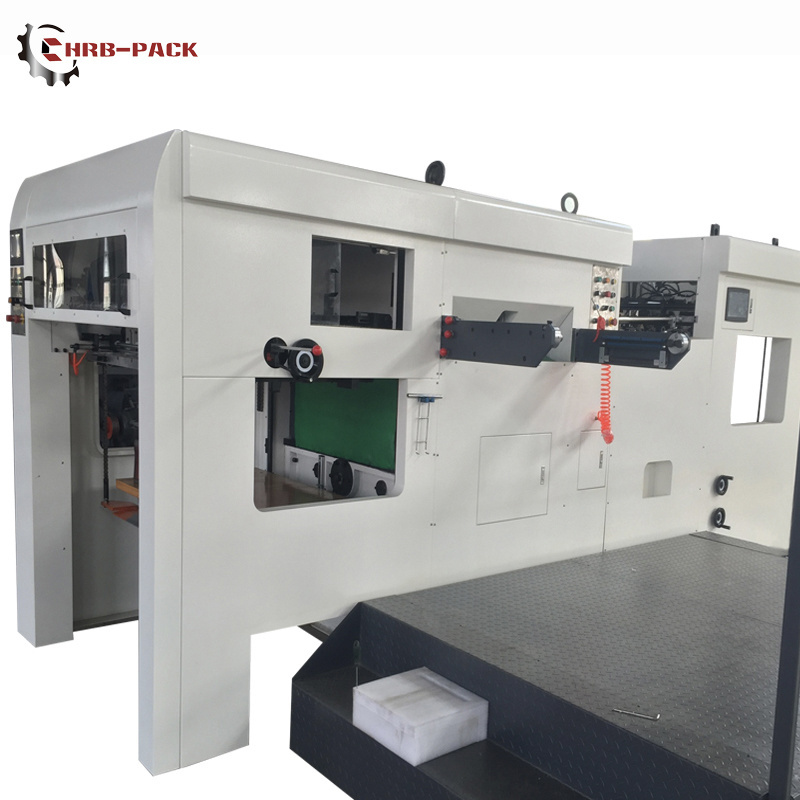

*Pressure part is high strength ductile iron QT500-7, special process casting

*High strength, never deform

*The crankshaft is Japan imported advanced alloy steel, through special process

*German SEW manufacturing super abrasion worm, worm gear.

*Accurate pressure regulating system, easy to adjust under the condition of machine running.

*Automatic paper device, ensure the paper in order.

*Equipped electric automatic delivering, it is safe and convenient to deliver paper without stopping machine. *Main chain protective device.

*Anti-back device.

*Unique lateral positioning design, make each row of grippers in one positioning line.

*Unique lateral positioning design, make each row of grippers in one positioning line.

*Gripper positioning compensation device, ensure the stability of the die cutting precision.

*Adjustable front and back positioning system, accurate positioning and easy adjustment.

*Moving plate scissor cutting, make the pressure is uniform and high.

*German imported torsion limits protector, avoid any damage to the machine caused by an emergency, and ensure machine safety and personnel safety.

*Convenient knife template turn-over device.

*Power supply lubrication system, main chain microcomputer control automatic intermittent lubrication.

*Italy kelunbo high precision 240°intermittent mechanism make five rows

*Of grippers to run smoothly, accurate precision and low noise.

*Italy OMPI imported pneumatic clutch device.

*Japan SMC High speed rotary connector.