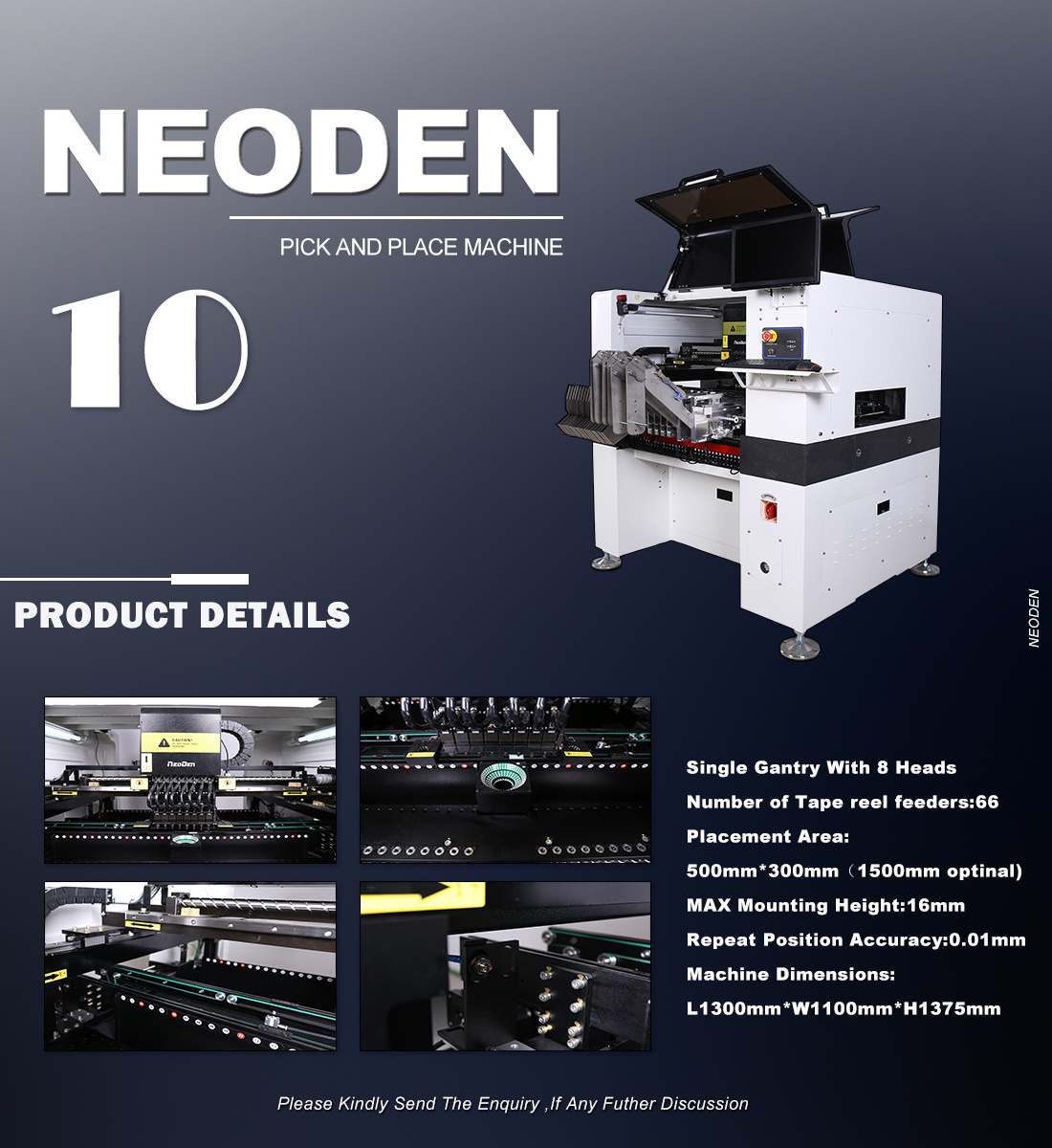

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

NeoDen

-

Model Number:

-

NeoDen10

-

Number of Heads:

-

8

-

Number of Tape reel Feeders:

-

66(Electric/Pneumatic)

-

Placement Area:

-

500mm*300mm(1500mm optinal)

-

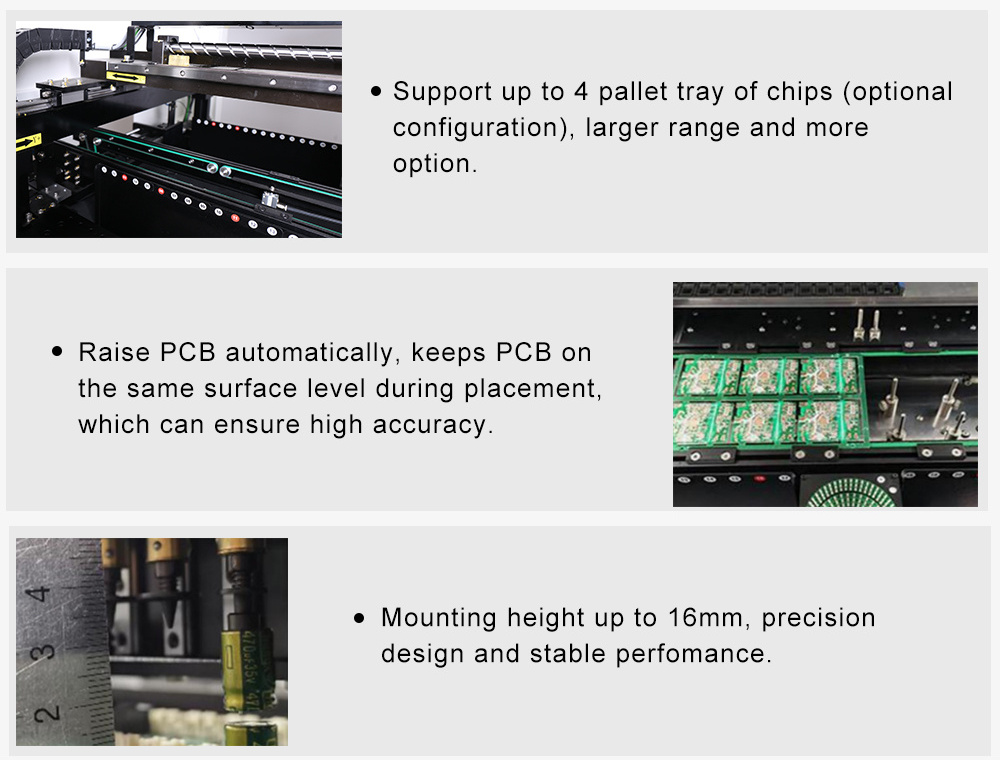

MAX Mounting Height:

-

16mm

-

Placement Accuracy:

-

±0.01mm

-

Maximum Mounting Speed:

-

18000CPH

-

Item:

-

high speed Pick And Place machine with Pneumatic feeder

-

X/Y Drive Type:

-

WON Linear Guide / THK Grinding screw C5 - 2040

-

Mark camera recognition system:

-

2 Groups (left and right) / US ON sensors

-

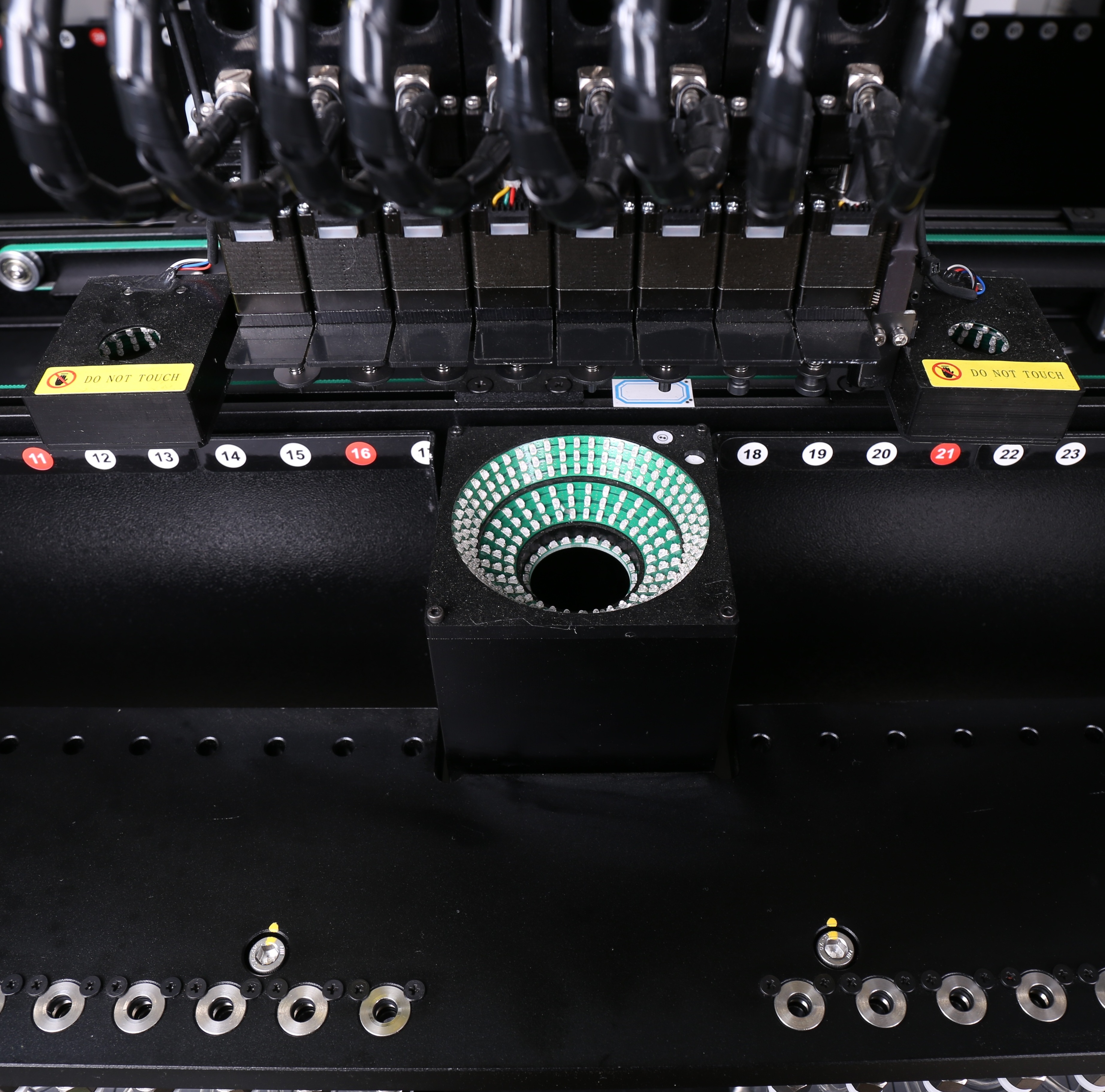

Flying camera recognition system:

-

2 Groups (front and rear) / US ON sensors

Quick Details

-

Weight (KG):

-

1100

-

Warranty of core components:

-

2 Year

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

NeoDen

-

Model Number:

-

NeoDen10

-

Number of Heads:

-

8

-

Number of Tape reel Feeders:

-

66(Electric/Pneumatic)

-

Placement Area:

-

500mm*300mm(1500mm optinal)

-

MAX Mounting Height:

-

16mm

-

Placement Accuracy:

-

±0.01mm

-

Maximum Mounting Speed:

-

18000CPH

-

Item:

-

high speed Pick And Place machine with Pneumatic feeder

-

X/Y Drive Type:

-

WON Linear Guide / THK Grinding screw C5 - 2040

-

Mark camera recognition system:

-

2 Groups (left and right) / US ON sensors

-

Flying camera recognition system:

-

2 Groups (front and rear) / US ON sensors

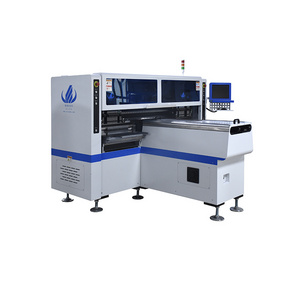

SMD Machines NeoDen10 Printed Circuit Board Machines Pick and Place Machine

Specification

|

Model

|

|

NeoDen10

|

|

|

|||

|

Nozzle Qty

|

|

8 nozzles

|

|

|

|||

|

Reel Tape Feeder Qty(Max)

|

|

66 (Electric / Pneumatic)

|

|

|

|||

|

IC Tray Feeder Qty

|

|

20

|

|

|

|||

|

Placement Area

|

|

500mm*300mm(1500mm*300mm optional)

|

|

|

|||

|

MAX Mounting Height

|

|

16mm

|

|

|

|||

|

Mark camera recognition system

|

|

2 Groups (left and right) / US ON sensors

|

|

|

|||

|

Flying camera recognition system

|

|

2 Groups (front and rear) / US ON sensors

|

|

|

|||

|

Operation System

|

|

Patented SMT Mouting Operation System V1.0

|

|

|

|||

|

XY Motion feedback control

|

|

right-left/left-right SPM/IBG magnetic linear encoder

|

|

|

|||

|

XY Drive motor

|

|

servo motor

|

|

|

|||

|

Repeat Position Accuracy

|

|

0.01mm

|

|

|

|||

|

Maximum Mounting Speed

|

|

18000CPH

|

|

|

|||

|

Average Mounting Speed

|

|

13000CPH

|

|

|

|||

|

X/Y Drive Type

|

|

WON Linear Guide / THK Grinding screw C5 - 2040

|

|

|

|||

|

Compressed Air

|

|

>0.6Mpa ,Max. flow rate 37L/min

|

|

|

|||

|

Voltage

|

|

AC110V/220V,50HZ/60HZ

|

|

|

|||

|

Net Weight

|

|

1100KGS

|

|

|

|||

|

Machine Dimension

|

|

L1300mm*W1100mm*H1375mm

|

|

|

|||

Product Description

NeoDen10

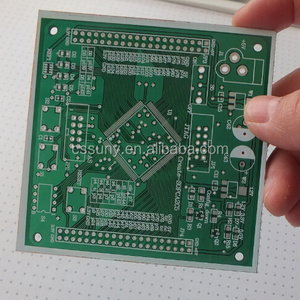

is a ball screw pick and place machine with 8 simultaneous pick-up heads, max 66 tape reel feeder capacity, max 18000CPH placement rate, which is suitable for scale PCB/LED assembly production in SMT line with fast speed and high accuracy.

NeoDen10 is compatiable with both electric feeder and pneumatic feeder

NeoDen10 is compatiable with both electric feeder and pneumatic feeder

The feeder sizes vary, 8mm/ 12mm/ 16mm/ 24mm/ 32mm/ 44mm/ 56mm.

The pneumatic feeder is cost-effective and stable, you can use it for components above 0201, such as 0402 and 0603, etc.

The cost of electric feeder is higher, but it's accurate and stable enough for small footprint 0201.

The pneumatic feeder is cost-effective and stable, you can use it for components above 0201, such as 0402 and 0603, etc.

The cost of electric feeder is higher, but it's accurate and stable enough for small footprint 0201.

You can combine both type feeders to improve the capacity at a competitive price.

Applicable components range: 0201, 0402, 0603, 0805, 1206, 1210, SOP, SSOP, SOC, QFP, QFN, BGA, 3538, 4148 diode, 3535 ball shape LED, 5050 etc.

Application industry: household appliances industry, auto electronics industry, power industry, LED industry, security,

instruments and meters industry, communication industry, intelligent control industry, internet industry of things and military industry, etc.

Applicable components range: 0201, 0402, 0603, 0805, 1206, 1210, SOP, SSOP, SOC, QFP, QFN, BGA, 3538, 4148 diode, 3535 ball shape LED, 5050 etc.

Application industry: household appliances industry, auto electronics industry, power industry, LED industry, security,

instruments and meters industry, communication industry, intelligent control industry, internet industry of things and military industry, etc.

Highlights

Related Products

Placement Effect

About Us

「

About NEODEN

」

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

With global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production. We provide professional solution of one-stop SMT equipment.

In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist everywhere.

FAQ

Q1: Do you provide software updates?

For customers who buy our machine, we can offer free upgraded software for you.

Q2: Does our machine need air compressor?

NeoDen4 and NeoDenYY1 have vacuum pumps inside the machine, no extra air compressor is required.

For customers who buy our machine, we can offer free upgraded software for you.

Q2: Does our machine need air compressor?

NeoDen4 and NeoDenYY1 have vacuum pumps inside the machine, no extra air compressor is required.

For

NeoDenK1830(NeoDen8), NeoDen9, NeoDen10, an extra air compressor above

0.6Mpa is needed.

Q3: This is the first time I use this kind of machine, is it easy to operate?

We provide tutorial videos and user manual and online support. As as mentioned, our machines are fully configured before shipping, you only need to power on and install feeder to make it work. The programming is easy, and we will guide you step by step if the video isn't helpful for you.

Q3: This is the first time I use this kind of machine, is it easy to operate?

We provide tutorial videos and user manual and online support. As as mentioned, our machines are fully configured before shipping, you only need to power on and install feeder to make it work. The programming is easy, and we will guide you step by step if the video isn't helpful for you.

We have sold thousands of machines over the world in past 13 years, and this is the way how most customers learned how to operate in 1-3 days.

NeoDenK1830(NeoDen8), NeoDen9, NeoDen10

have remote control system, if necessary, our engineer will control and machine and provide support. Usually all problems can be solved by sharing a video of the error message with us.

Q4: How about the warranty?

We provide 2 years warranty for NeoDen4, NeoDenK1830(NeoDen8), NeoDen9, NeoDen10, IN6 and IN12.

Q4: How about the warranty?

We provide 2 years warranty for NeoDen4, NeoDenK1830(NeoDen8), NeoDen9, NeoDen10, IN6 and IN12.

The other items carry 1 year

warranty.

During this period,

any damaged parts will be shipped via DHL to you without charge.

Q5: How can I buy machine from you?

(1) Consult us on line or by e-mail;

(2) Negotiate and confirm the final price, shipping, payment method and other terms;

(3) Send you the proforma invoice and confirm your order;

(4) Make the payment according to the method put on proforma invoice;

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping;

(6) Send your order via express or by air or by sea.

Q5: How can I buy machine from you?

(1) Consult us on line or by e-mail;

(2) Negotiate and confirm the final price, shipping, payment method and other terms;

(3) Send you the proforma invoice and confirm your order;

(4) Make the payment according to the method put on proforma invoice;

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping;

(6) Send your order via express or by air or by sea.

Contact us now to get more detailed information.

Hot Searches