electricity for households .

The production of bottom ash is rising because MSW is increasingly incinerated. Bottom ash is land filled in many

countries.However, the material is suitable as a building material from a civil engineering viewpoint, e.g. for embankments and

foundations of roads.

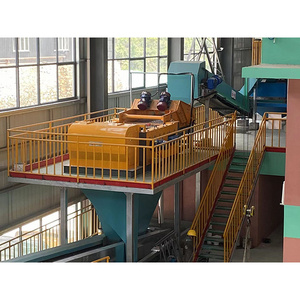

Bottom ash contains a considerable amount of non-ferrous and ferrous metals that should be removed for such an application.such as ferrous metals , heavy copper , light aluminum .and a significant proportion of noble metals such as gold and silver are present in the <2 mm grain range.