- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

200-5000L

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

Guangdong,China(mainland)

-

Brand Name:

-

Sipuxin, Sipuxin

-

Voltage:

-

220V/380V,50Hz-60Hz

-

Dimension(L*W*H):

-

Referring

-

Power (kW):

-

11 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Name:

-

Liquid detergent blending mixer

-

Material:

-

Stainless Steel 304 / SUS316L

-

Heating:

-

Electric or Steam Heating

-

Homogenizer Speed:

-

0-3000r/min

-

Function:

-

Blending mixer

-

Used for goods:

-

Liquid detergent, shampoo, lotion

-

Capacity:

-

Customized

-

Power(W):

-

1.5~40kw

Quick Details

-

Barrel Volume (L):

-

1000

-

Max. Loading Volume (L):

-

2000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 63 r.p.m

-

Max. Loading Capacity:

-

200-5000L

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

Guangdong,China(mainland)

-

Brand Name:

-

Sipuxin, Sipuxin

-

Voltage:

-

220V/380V,50Hz-60Hz

-

Dimension(L*W*H):

-

Referring

-

Power (kW):

-

11 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Name:

-

Liquid detergent blending mixer

-

Material:

-

Stainless Steel 304 / SUS316L

-

Heating:

-

Electric or Steam Heating

-

Homogenizer Speed:

-

0-3000r/min

-

Function:

-

Blending mixer

-

Used for goods:

-

Liquid detergent, shampoo, lotion

-

Capacity:

-

Customized

-

Power(W):

-

1.5~40kw

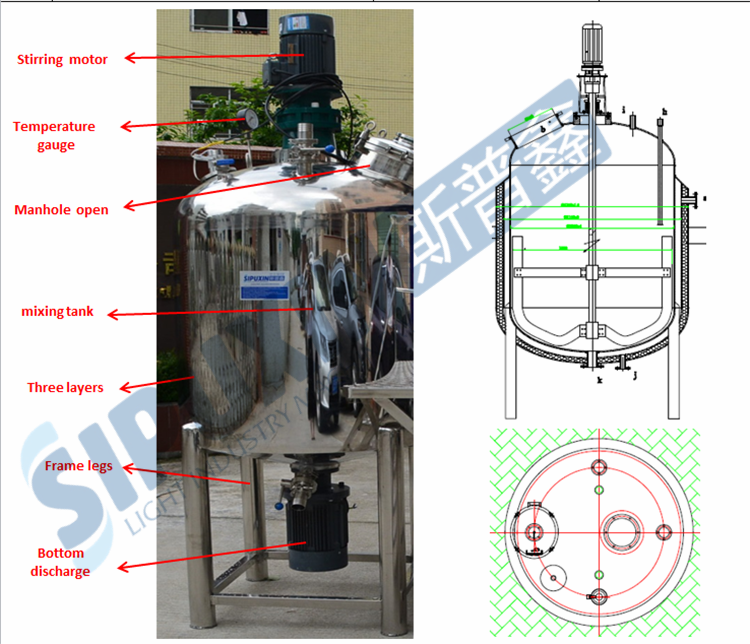

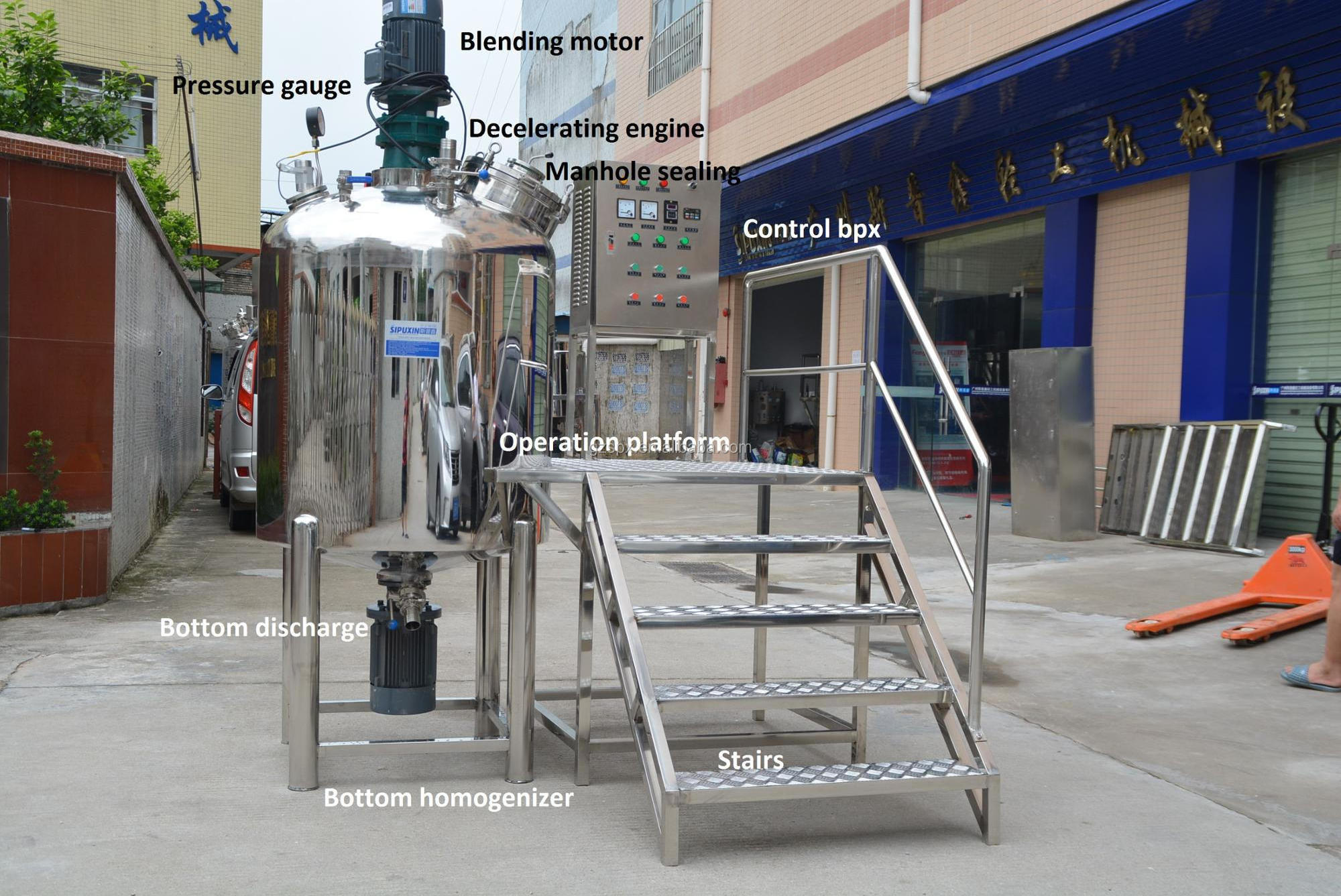

Bleach Making Machine Toilet Cleaning Liquid Soap Production Line

Application:

1. The unit mainly used for manufacturing liquid products(such as detergent,shampoo, shower gel,etc.), it is composed of main pot, auxiliary boiler, stainless steel feeding pump, bracket platform, control system.

Machine introduction:

2. The all-round scraping mixer adopts frequency converter for speed adjustment.

3. The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and rapidly dissolve many indissoluble material like AES, AESA,LSA,etc, saving energy consumption and shortening production period.

4. The pot body is welded by imported three-layer stainless steel plate.The pot body and pipes adopt mirror polishing, which fully conforms to GMP requirements.The tank can heat and cool materials.

5. The heating way include steam heating and electric heating.Easy to discharge, bottom direct discharge or by transfer pump.

Technical Parameter

|

Technical Parameter |

||||||

|

Specification |

Volume (L) |

Blending power (kw) |

Blending rotation speed (r/min) |

Homogenizing power (kw) |

Homogenizing rotation speed (r/min) |

Heating method |

|

SJB-Z-200 |

200 |

1.5 |

0-65 |

3 |

3000 |

Steam heating Or Electric heating

|

|

SJB-Z-500 |

500 |

2.2 |

0-65 |

4 |

3000 |

|

|

SJB-Z-1000 |

1000 |

2.2-4 |

0-65 |

7.5 |

3000 |

|

|

SJB-Z-1500 |

1500 |

4-5.5 |

0-65 |

11 |

3000 |

|

|

SJB-Z-2000 |

2000 |

5.5 |

0-53 |

11 |

3000 |

|

|

SJB-Z-3000 |

3000 |

7.5 |

0-53 |

15 |

1500 |

|

|

SJB-Z-5000 |

5000 |

11 |

0-53 |

22 |

1500 |

|

Application

You May Like

Our Project

Guangzhou Sipuxin Light Industry Machinery Co., Ltd. is a professional manufacturer and supplier of cosmetics machinery, pharmaceutical equipment, food machines and water purify equipment. Our main production lines are Cream/ Liquid/Perfume Line, main products include vacuum homogenizing emulsifier, blending mixer, RO water treatment, storage tank, various bottles filling capping machine, labeling machinecode, inkjet printer and other cosmetic and perfume whole-set production line. With solid backing from Yangzhou Sipuxin Light Industry Machinery equipment Co, Ltd, Sipuxin has become a brand enterprise in daily chemical machinery industry.

Our support customers in factory design, model selection and provides one-stop considerate service including product design, reserach and development, production, enginnering iinstallation, technical consultation and after-sales maintenance, serving for many famous enterprises in domestic and abroad.

Our machinery have passed Ce certification and coincident with GMP standerd.

Shown Room

* We pay more attention to every machine's packing and loading, also check carefully before shipping.

* All of our machine are packed in ply wooden case, which is safe for shipping.

Been the machine manufucturer, we have been regular customers around the world. We do want to cooperate with the fresh and old customer with "Professional design experience, Leading manufacturing technology, Excellent equipment, and Sincere operation"concepts, in order to create the prosperous future hand in hand. Welcome all the friends at home and abroad to visit, guide, and negotiate business.

* Pre-sale: According to email communication or further more communication to make sure the details about the machine.

*

Under-sale

: We make sure to check the machine before the shipping, and for machines, we support 1 years warranty and lifelong positive service.

*

After-sale:

We can install the machine in your factory, but the cost of accommodation, air ticket, and technician fee will be on your account. However, for small machine, we can install here and shooting the video to send you. When you get the machines, you operate on basic of operation instruction and video.

1. I'm new in our industry, but I'm planning to set up a factory, What can I do?

We can suggest customer the most suitable machine according to their formula, Raw material. Manufacturing- Installation- Training- Maintenance- Technical Support. We can introduce you supplier of raw material, bottles, labels etc. We could take you to our customer's factory to learn how they produce. We could customize machines according to your real need, We could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

2. We can recommend you the whole production line depends on what products you will make:

(1). If for paste or cream product, the following machine we will recommend you:

RO water treatment equipment → Vacuum homogenizer → Storage tank → Paste filling machine or Heating mixing filling machine → Capping machine → Labeling machine → Inkjet printer → Shrink film packing machine etc.,

(2). If for liquid product, the following machine we will recommend you:

RO water treatment equipment → Blending tank → Storage tank → Liquid filling machine → Capping machine → Labeling machine → Inkjet printer → Shrink film packing machine etc.,

(3). If for Perfume, the following machine we will recommend you:

RO water treatment equipment → Perfume making machine → Perfume storage tank → Perfume filling machine → Perfume crimping machine → Perfume collar machine → Inkjet printer → Shrink film packing machine et.,

(4). There are Full automatic production line and Semi automatic production line for your option.

3. What is your payment term?

We usually pay by T/T, 40% deposit after sales confirmation, 60%before delivery.

4. What is your delivery day?

Our delivery day is about 15-30 days after receive the deposit.