1.

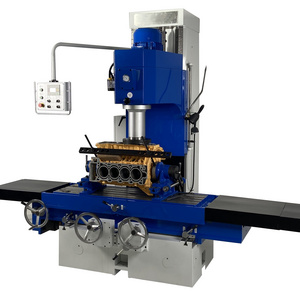

Integrated bed design, "+" reinforcement layout, strong support guide rail.

2.

The column section is optimized according to the force analysis, the rigidity is strong, the inertia is small.

3.

The spindle speed is 2000 rpm, 3000 rpm is optional.

4.

The structure is tight, the transmission is stable, the vibration, impact and noise are small.

5.

X, Y, Z axis adopts heavy-duty roller linear guide, strong rigidity, good dynamic accuracy.