- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HD-AA508

-

Specimen area:

-

minimum size 230*50mm

-

Friction speed:

-

(43±1) times/min (21, 43, 85, 106 times/min adjustable)

-

friction load:

-

908g (2LB), 1810g (4LB). 2040g (national standard 20N)

-

Friction stroke:

-

about 60mm

-

Friction area:

-

50X100mm (LxW)

-

weight:

-

about 18kg

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

China

-

Brand Name:

-

HD

-

Model Number:

-

HD-AA508

-

Specimen area:

-

minimum size 230*50mm

-

Friction speed:

-

(43±1) times/min (21, 43, 85, 106 times/min adjustable)

-

friction load:

-

908g (2LB), 1810g (4LB). 2040g (national standard 20N)

-

Friction stroke:

-

about 60mm

-

Friction area:

-

50X100mm (LxW)

-

weight:

-

about 18kg

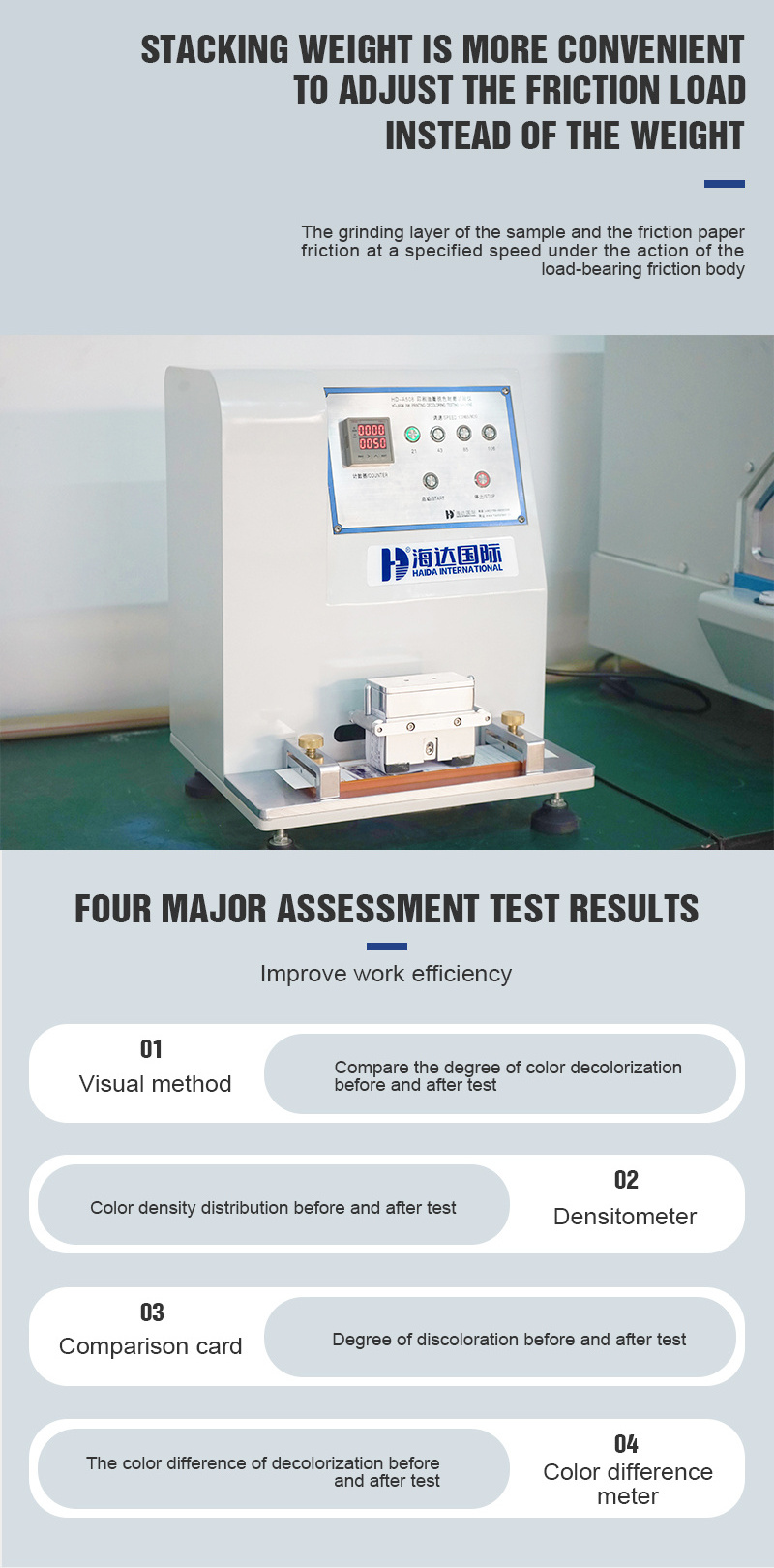

Hot Selling Ink Print Decolorization Testing Machine Ink Rub Tester Price/Ink Testing Machine

Ink Discoloration Tester is mainly suitable for the abrasion resistance test of printing ink layer of printed matter. Wrap standard size friction paper on the friction head, rub the surface of the sample at a specified speed and pressure, and observe the ink layer falling off of the sample.

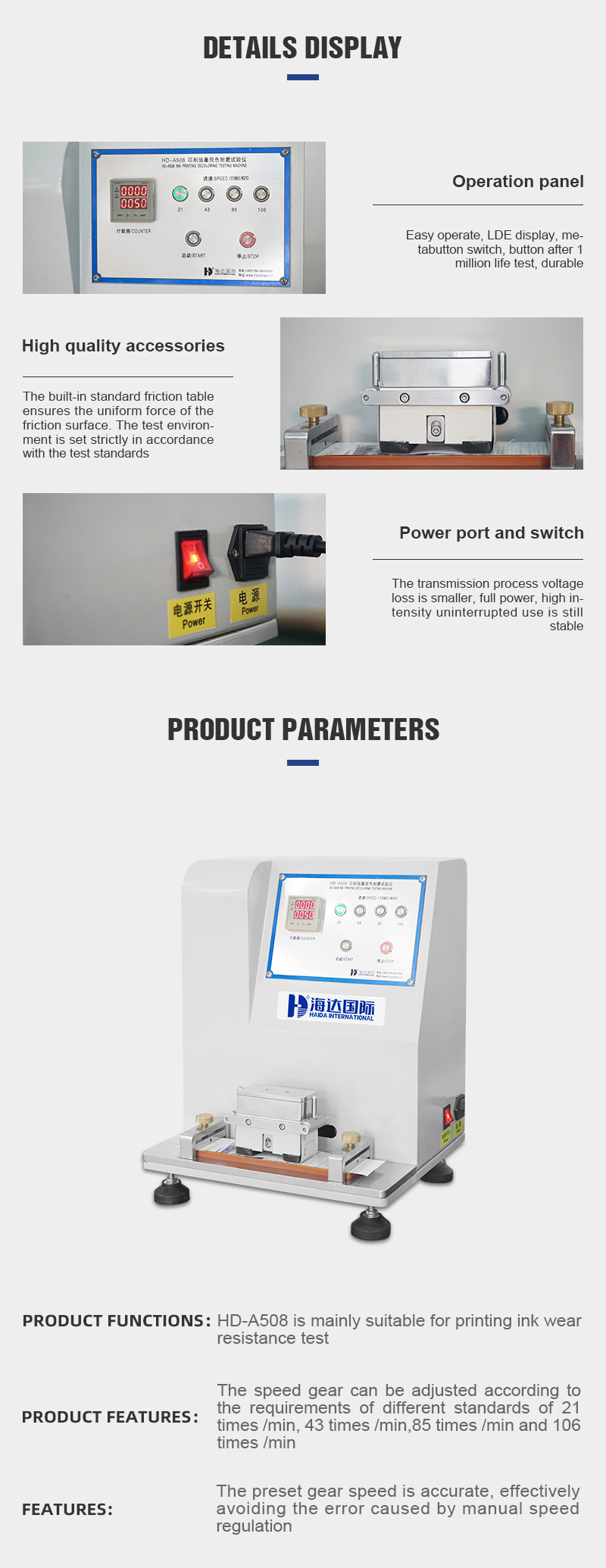

Main technical parameters:

| Specimen area | minimum size 230*50mm |

| Friction stroke | about 60mm |

| Friction speed | (43±1) times/min (21, 43, 85, 106 times/min adjustable) |

| Friction load | 908g (2LB), 1810g (4LB). 2040g (national standard 20N) |

| Friction area | 50×100mm (L*W) |

| Use power supply | 1, AC220V, 60W |

| Dimensions | 330*300*410mm(L*W*H) |

Principle of Operation:

The sample's layer to be rubbed and the friction paper rub against each other at a specified speed under the action of the load friction body, and the wear resistance of the ink layer or coating can be judged by measuring the change in the density of the ink layer or the thickness of the coating before and after rubbing.

Test Standards:

IS-5071-1- "Lithographic Printing Inks", GB/T 7706-2008 "Toppan Decoration Prints", GB/T 7705-2008-"Lithographic Decorations", TAPPI-UM486

Features:

(

1) Structural features

1. The speed gear can be adjusted according to the test requirements of different standards, 21 times/Min, 43 times/Min, 85 times/Min and 106 times/Min can be selected;

2. The built-in standard friction table ensures uniform force on the friction surface, and the test environment is set in strict accordance with the test standards;

3. The use of superimposed weights to adjust the friction load, it is more convenient for users to replace weights.

(2) Functional characteristics

1. It can carry out abrasion resistance test on printing paper ink layer, plastic film coating, PS plate photosensitive layer and other materials, with a wide range of applications;

2. The preset gear speed is accurate, effectively avoiding errors caused by manual speed regulation.