- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2000*800*1500mm

-

Power (kW):

-

30 kW

-

Weight (KG):

-

2000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

waste bicycle/truck/car tire

-

Name:

-

Automatic hydraulic waste tyre wire bead removal machine single hook

-

Application:

-

single hook tyre wire removal

-

Product name:

-

tyre recycling machine

-

Function:

-

Tire Powder Recycling Machine

-

Usage:

-

Used Tire Recyling

-

End product:

-

rubber powder

-

Weight:

-

1800kg

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

PAND

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

2000*800*1500mm

-

Power (kW):

-

30 kW

-

Weight (KG):

-

2000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

waste bicycle/truck/car tire

-

Name:

-

Automatic hydraulic waste tyre wire bead removal machine single hook

-

Application:

-

single hook tyre wire removal

-

Product name:

-

tyre recycling machine

-

Function:

-

Tire Powder Recycling Machine

-

Usage:

-

Used Tire Recyling

-

End product:

-

rubber powder

-

Weight:

-

1800kg

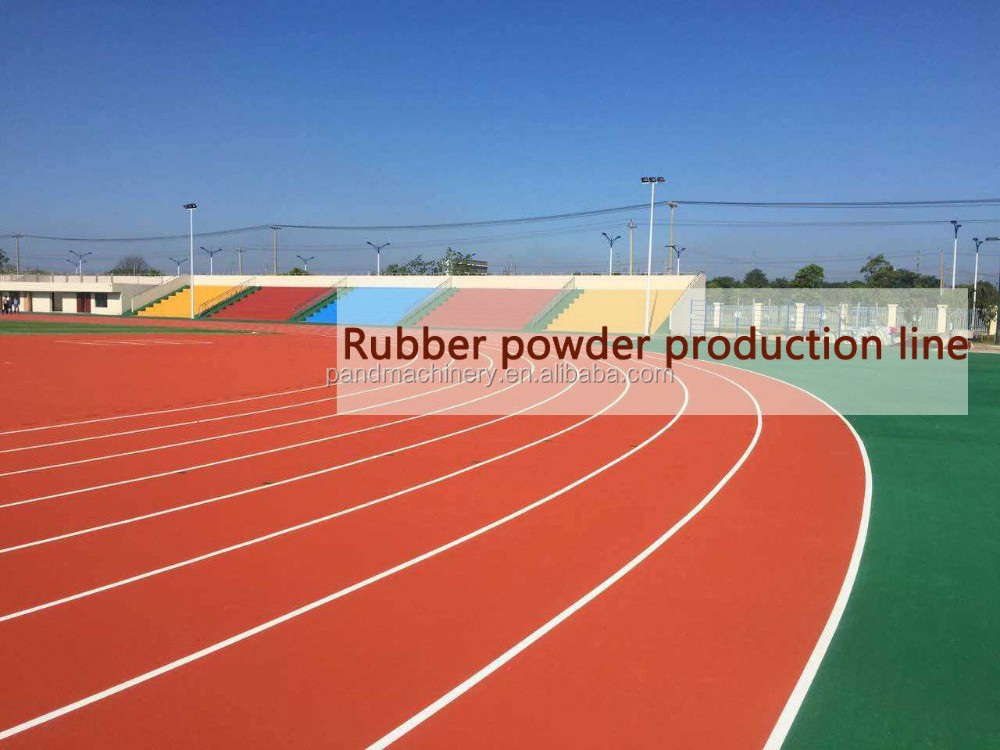

Product Application for Automatic hydraulic waste tyre wire bead removal machine single hook tyre recycling machine

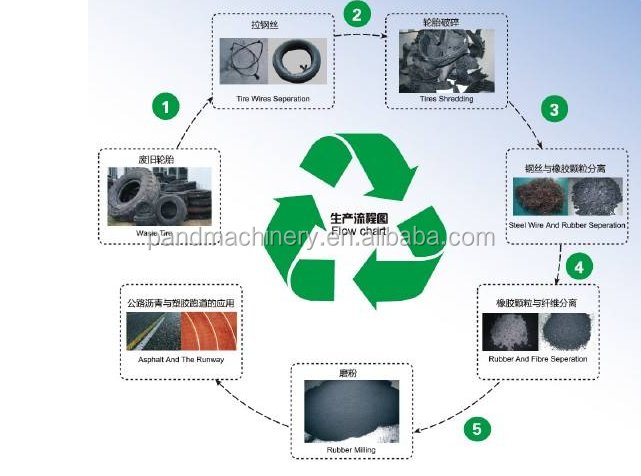

The Automatic hydraulic waste tyre wire bead removal machine single hook tyre recycling machine adopt newest technology. It is utilized in separation among the tire crown, tire side-wall, and bead of water tires, and it is the fist process of recycling waste tires. Features: The materials of blade is excellent hard alloy, so the blade is high hard and wearable.

Main Features of Automatic hydraulic waste tyre wire bead removal machine single hook tyre recycling machine

designed for recycling waste tires from multiple sources such as cars, commercial vehicles, trucks etc. The recycling process includes shredding and wire/fiber separation to produce pure rubber fine powder, then use the powders to produce the eco-friendly rubber product like rubber flooring mat,rubber bricks and rubber flooring roll. Tire bead removing machine/ tire steel removing machine / bead wire separator

1. Automatic tyre feeding system, no pre-shredding or wire de-beading demanded;2. All-in-one recycling process - from tyres to granules,production to packaging - no secondary handling process;

3. Maximum throughput up to 5000kg/h, with no more than 7 operators demanded;

4. Multiple options of equipment models to meet diverse requirements of capacity,200kg/h - 5000kg/h;

5. Full assembly two-floor infrastructure makes assembly and maintenance easier and safer;

6. Seamless assembly joints enable perfect control of dust and smoke;

7. 80-100 hour "real world" testing on principal machines ensures stable performance;

8 .CE certification: uniform standard and fine workmanship.

| recycle machine |

Machine Parts

Automatic hydraulic waste tyre wire bead removal machine single hook tyre recycling machine

Main Features

Automatic hydraulic waste tyre wire bead removal machine single hook tyre recycling machine

Automatic hydraulic waste tyre wire bead removal machine single hook tyre recycling machine

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

Automatic hydraulic waste tyre wire bead removal machine single hook tyre recycling machine

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Automatic hydraulic waste tyre wire bead removal machine single hook tyre recycling machine

The packing&delivery of Automatic hydraulic waste tyre wire bead removal machine single hook tyre recycling machine

1. Terms: 30% TT as deposit, 70% before delivery.

2. Delivery period: 15~30 days after receiving your deposit.

3. Warranty period: 2 year.

24 hours severice!

Name: Jean Yang

Tel&Whatsapp&Wechat&Skype: +8617335778675

Automatic hydraulic waste tyre wire bead removal machine single hook tyre recycling machine

Welcome visit our factory and do the business together!

Tire cutting tools

Plastic crusher

Waste tire/plastic pyrolysis plant