- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.4-0.8 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

as request

-

Dimension(L*W*H):

-

5000*1400*1600

-

Weight:

-

3000 kg

-

Marketing Type:

-

Hot Product

-

Product name:

-

machine to manufacture steel profiles

-

transport:

-

by Gear

-

Roll material:

-

45# high grade steel

-

Shaft material:

-

45# steel with tempering

-

Frame material:

-

300 H-high grade steel

-

Cutting blade material:

-

45# steel with tempering

-

After-sales Service Provided:

-

Online Support Video Technical Support

-

Control system:

-

PLC(detla) System

-

Profiles:

-

customized

-

certification:

-

CE ISO

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15-20m/min

-

Rolling thinckness:

-

0.4-0.8 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

as request

-

Dimension(L*W*H):

-

5000*1400*1600

-

Weight:

-

3000 kg

-

Marketing Type:

-

Hot Product

-

Product name:

-

machine to manufacture steel profiles

-

transport:

-

by Gear

-

Roll material:

-

45# high grade steel

-

Shaft material:

-

45# steel with tempering

-

Frame material:

-

300 H-high grade steel

-

Cutting blade material:

-

45# steel with tempering

-

After-sales Service Provided:

-

Online Support Video Technical Support

-

Control system:

-

PLC(detla) System

-

Profiles:

-

customized

-

certification:

-

CE ISO

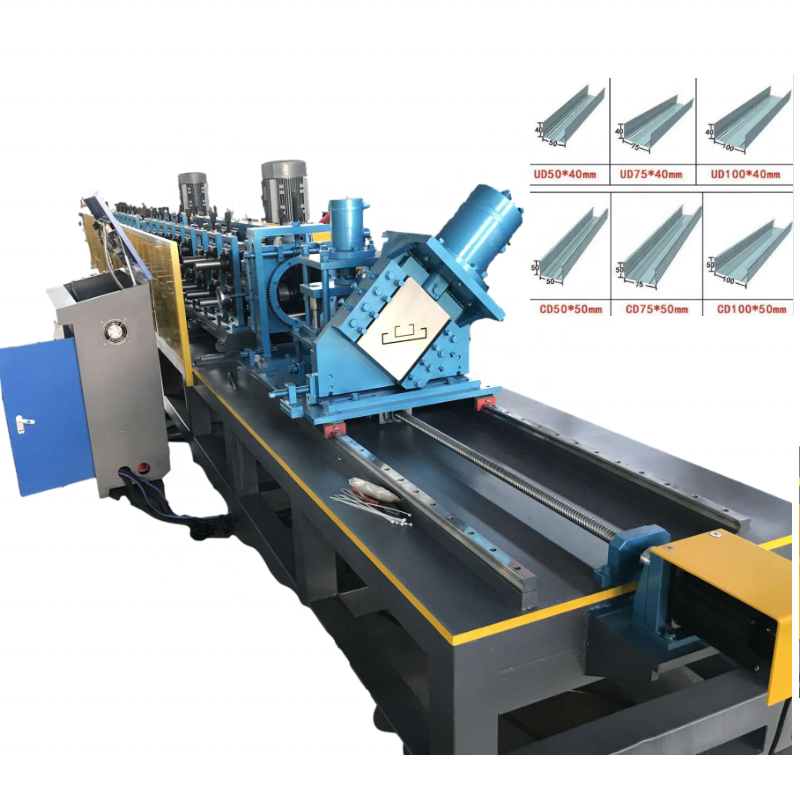

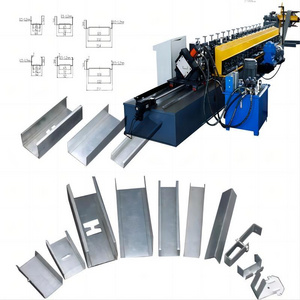

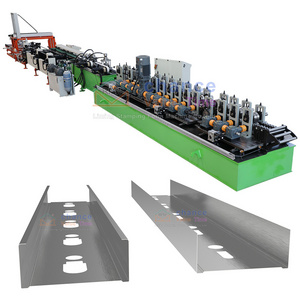

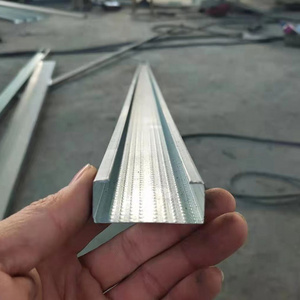

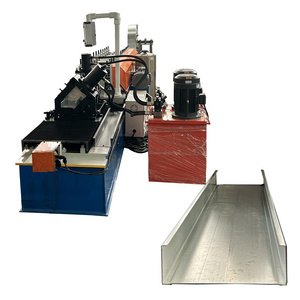

Machine to manufacture steel profiles stud and track roll forming machine metal CD UD CW UW drywall plaster machine

|

Product name |

c channel steel roll forming machine |

|||

|

NO. |

Items |

Parameters |

Remark |

|

|

1 |

Suitable Material |

Type |

GI/PPGI/AL |

|

|

Thickness |

0.40-0.80mm |

|||

|

2 |

Product Specifications |

Length |

Any length |

|

|

Length Tolerance |

±1mm |

|||

|

3 |

Working Speed |

35m/min |

Standard machine |

|

|

4 |

Control System |

Mitsubishi/Siemens PLC& transducer |

Custom |

|

|

5 |

Total Power |

6KW |

||

|

6 |

Total Weight |

About 3T |

Up to final design |

|

Components of c channel steel roll forming machine

|

No. |

Name |

Unit |

Qty |

|

1 |

Manual decoiler |

set |

1 |

|

2 |

Main forming machine |

set |

1 |

|

3 |

PLC control system |

set |

1 |

|

4 |

Hydraulic pump station |

set |

1 |

|

5 |

Post cut |

set |

1 |

|

6 |

Electric motor |

set |

1 |

|

7 |

Output table |

set |

1 |

Un-coiler System

|

Loading capacity |

Uncoiling width |

Inner diameter |

|

1.5T |

300mm |

450-550mm |

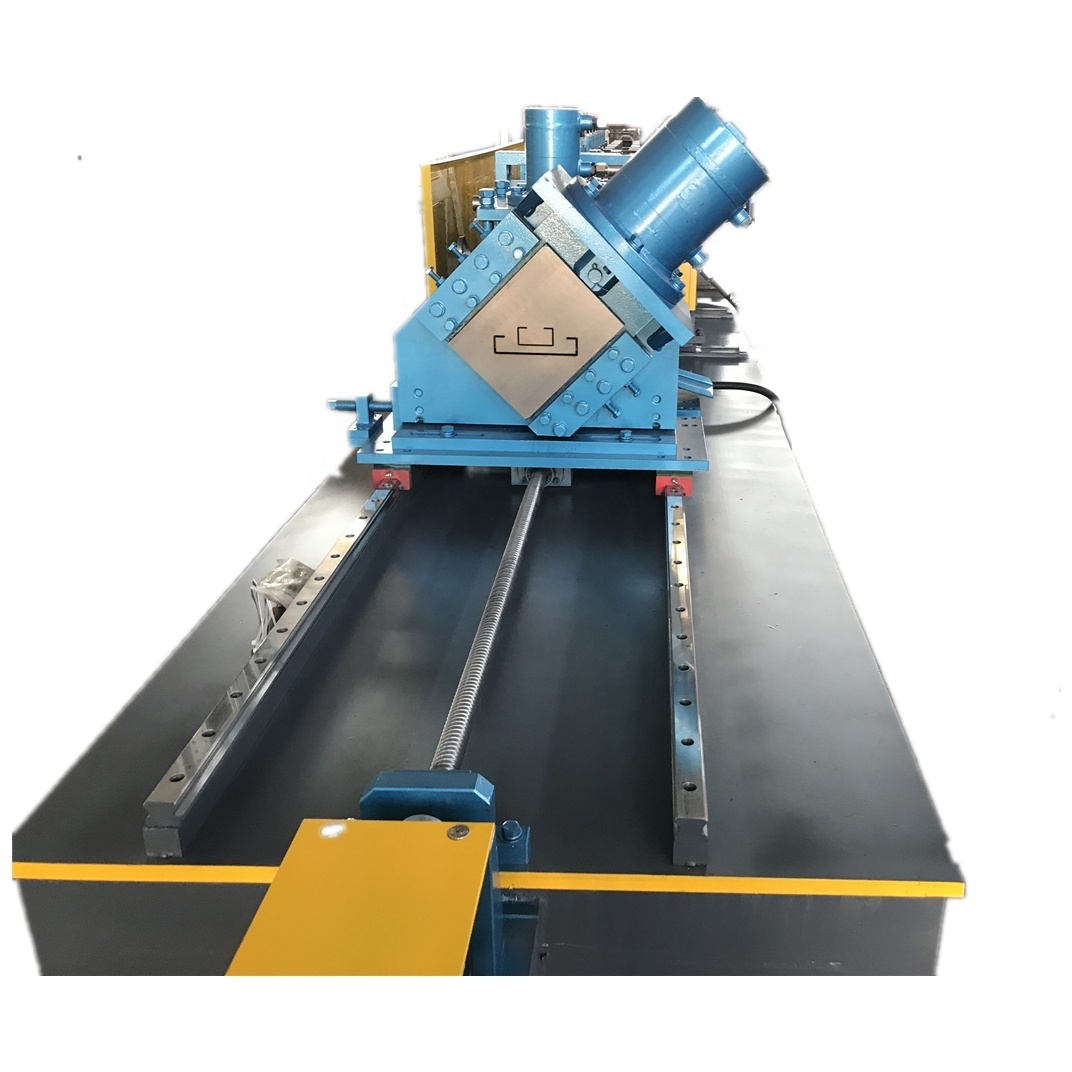

Forming device of c channel steel roll forming machine

|

No. |

M ain parameter of c channel steel roll forming machine |

|

|

1 |

Length of the main part |

3000*800*1400mm |

|

2 |

Weight of main part |

About 3 t |

|

3 |

Voltage |

380V/50HZ3Phase |

|

4 |

Roller fixer |

Guide column |

|

5 |

Frame |

Middle plate welded Memorial arch frame type |

|

6 |

Frame thickness |

25mm |

|

7 |

Drive mode |

Gear or chain |

|

8 |

Material of rollers |

45# steel with tempering |

|

9 |

Material of shafts |

45# steel with tempering |

|

10 |

Diameter of shafts |

φ40mm |

|

11 |

Number of rollers |

10 rollers |

|

14 |

Main power |

3kw |

Cutting device

|

Blade Material |

Cutting system |

|

Cr12 steel with quenched treated 60-62°C |

Full automatic |

Controlling device

|

S creen |

PLC |

C oder |

|

Touch screen displayer |

Delta from Taiwan |

Omron |

Hydraulic station

|

Orgin |

Power |

|

Advanced hydraulic system |

3kw |