- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Industrial

-

Chemical Composition:

-

steel

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Weijia

-

Model Number:

-

Custom

-

Product name:

-

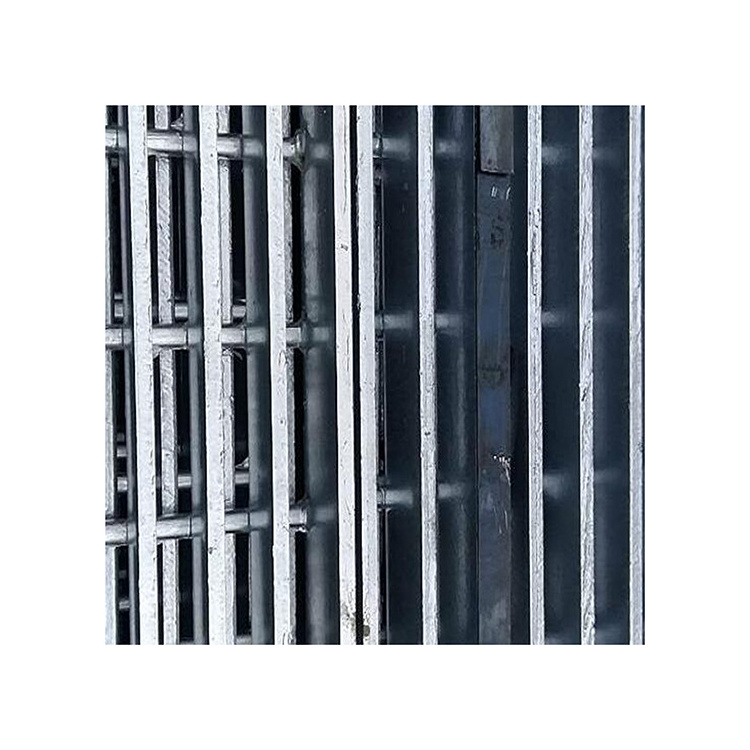

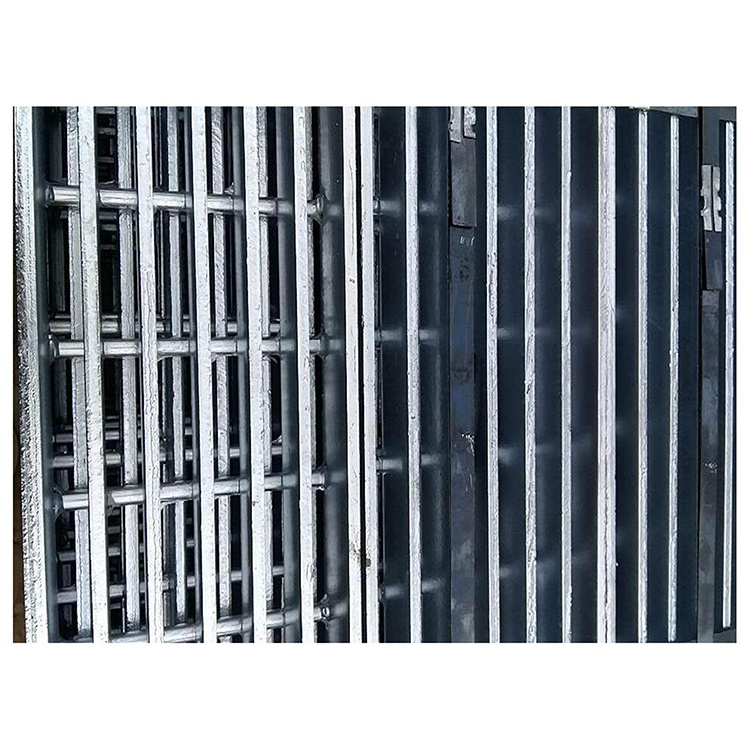

galvanized garage drainage channel drain floor grates / grate drains

-

Keywords:

-

galvanized garage drainage channel drain floor grates / grate drains

-

Surface treatment:

-

Aluminum Alloy

-

Features:

-

Corrosion resistance, Rust resistance, Anti-slip resistance

-

Applications:

-

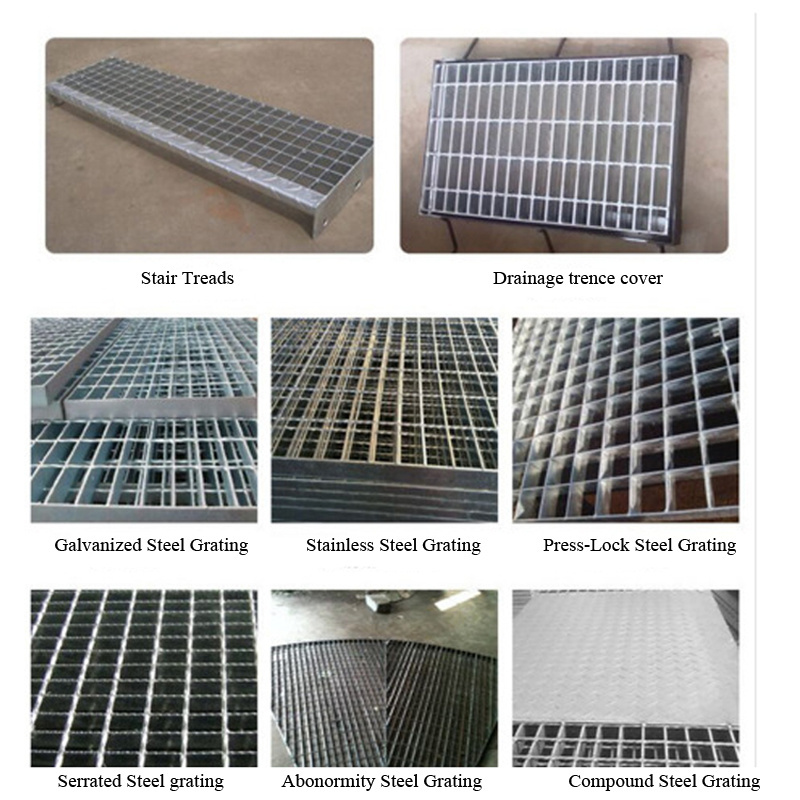

Industrial platform, flooring and walkway ,Stair treads,

-

Grating type:

-

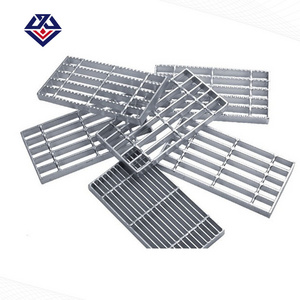

Plain type,I type, Serrated type,I type serrated

-

Trait:

-

Ventilation, lighting, heat dissipation, anti-slip, explosion proof

-

Steel Bar:

-

25x5mm 30x3mm 32x5mm 38x5mm 40x5mm 50x5mm

-

Related Product:

-

Drain Grating Covers

-

Related Product 2:

-

Metal Stair Treads

Quick Details

-

Warranty:

-

3 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Hotel

-

Design Style:

-

Industrial

-

Chemical Composition:

-

steel

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Weijia

-

Model Number:

-

Custom

-

Product name:

-

galvanized garage drainage channel drain floor grates / grate drains

-

Keywords:

-

galvanized garage drainage channel drain floor grates / grate drains

-

Surface treatment:

-

Aluminum Alloy

-

Features:

-

Corrosion resistance, Rust resistance, Anti-slip resistance

-

Applications:

-

Industrial platform, flooring and walkway ,Stair treads,

-

Grating type:

-

Plain type,I type, Serrated type,I type serrated

-

Trait:

-

Ventilation, lighting, heat dissipation, anti-slip, explosion proof

-

Steel Bar:

-

25x5mm 30x3mm 32x5mm 38x5mm 40x5mm 50x5mm

-

Related Product:

-

Drain Grating Covers

-

Related Product 2:

-

Metal Stair Treads

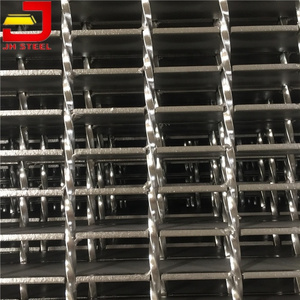

Steel Grating is made by the world first-class Italian ORSOGRIL equipment,which can arrange the bearing bar and cross bar in longitude and latitude order to certain distance. Cross bar is pressed into the bearing bar by high tension resistance welding which is controlled by computer. So we can produce high quality grating with firm welding,smooth surface and high strength.

HOT GALVANIZING

Normally,Hot galvanizing will be carried out after end welding process,For the thickness of bearing bars is not less than 5mm,the weight of average Zinc Layer will not be less than 610g/m2.When the thickness of bearing bars is less than 5mm,the weight of average Zinc Layer

Will not be less than 460g/m2. The quality and requirements after hot galvanizing are subject to the standards of GB/T 13912.

LACQUERING

To again protection layer through the ways of spraying,brushing and soaking.

SERVICE LIFE OF HOT GALVANIZING

Coated zinc thickness of 100um,the anticipated life of products in various circumstances.

ANTI-ACID AND ALKALI CORROSSION CAPACITY

The range of PH6 to PH12.5,a stable protective film will be formed on the zinc surface.it has good

anti-corrosive property.

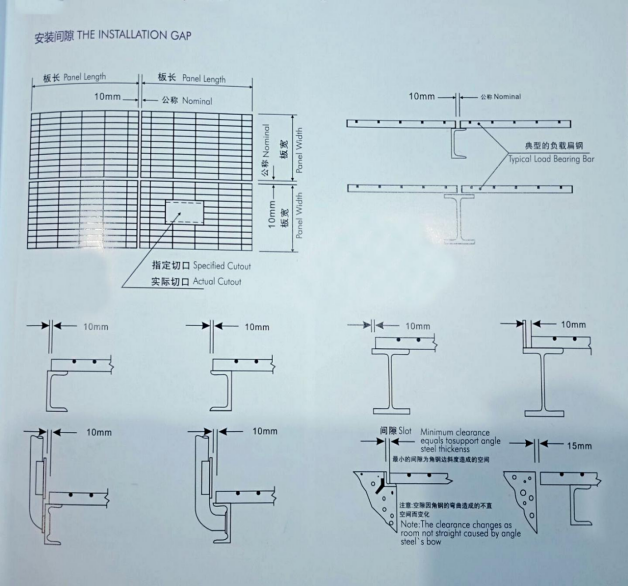

CALCULATION OF WEIGHT AND AREA

1. The weight of gratings varies after end welded and hot galvanizing process. For normal industrial platform using 30mm pitch bearing bars,the weight will increase 12%;14% for 40mm pitch bearing bars and 16% for 60mm pitch bearing bars.

2. For those gratings processed according to the size supplied by customer,calculation will based on the actual area(including cutout and tap)

3. For those gratings processed according to customer’s drawing,calculation will be based on the

total outside size(including cutout and tap)

4. For unusual size of grating cutouts shall not deduct from the length and width.

Description:

(1) Structure: Welding with flat steel and cross/round bars with certain distances.

(2) Features: High strength, light structure, high bearing.

(3) Surface: The hot dipped zinc coating gives the product excellent anti-corrosion.

Specification:

|

Common Specification Of Steel Grating |

|

|

Material Standard |

ASTM A36, A1011, A569, Q235, S275JR,Stainless steel 304, Mild steel & Low carbon steel, etc |

|

Bearing Bar (width*thickness) |

25x3, 25x4, 25x4.5, 25x5, 30x3, 30x4, 30x4.5, 30x5, 32x5, 40x5, 50x5, 65x5, 75x6, 75x10…..100 x10mm etc; I bar: 25x5x3, 30x5x3, 32x5x3, 40x5x3 etc US standard: 1''x3/16'', 1 1/4''x3/16'', 1 1/2''x3/16'', 1''x1/4'',1 1/4''x1/4'', 1 1/2''x1/4'', 1''x1/8'', 1 1/4''x1/8'', 1 1/2''x1/8'' etc |

|

Bearing Bar Pitch |

12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3,32.5, 34.3, 35, 38.1, 40, 41.25, 60, 80mm etc. US standard: 19-w-4, 15-w-4, 11-w-4, 19-w-2, 15-w-2 etc. |

|

Twisted Cross Bar Pitch |

38.1, 50, 60, 76, 80, 100, 101.6, 120mm, 2'' & 4'' etc |

|

Surface treatment |

untreated(black), hot-dipped galvanized ,powder coated, electroplate, painting or as per customers’ requirement. |

|

Grating Style |

Plain / Smooth, Serrated /teeth, I bar, serrated I bar |

|

Packing |

1) LCL(less than one container load): packed with plastic film then on the pallets 2) FCL(full container load): nude packing 3) Other special package :according to customers' requirements. |

|

Payment Term |

T/T,L/C, Paypal, Western Union, MoneyGram, Credit Card ,D/A,D/P, Trade assurance |

|

Remarks: Other sizes also can be customized according to customers’ requirement. |

|

INSTALLATION OF STEEL GRATING

1. There are two ways of installation for grating. One way is by welding and other is by using installation fastener. The welding method is suitable for those parts which will be fixed forever,such as platforms for equipments,while the method by using installation fastener has the properties of easy to assemble and disassemble and of preventing destroying the zinc layer.

2. Installation fastener is suitable for all types of gratings. It is made of up-fastener,down-fastener and inside cylinder bolt M10.

3. Welding method is angle welding at the first bearing bar of every corners on the grating.Welding seam of which is not less than 20mm length and not less than 3mm height.

4. It at least needs four sets of installation fasteners on every grating to fix.You had better install more fasteners on the supportable construction when the span is larger.

5. We can supply stainless steel installation fastener to satisfy our customer’s requirements.

6. Please indicate clearly the type,quantity and material when you purchase installation fastener.

Steel Grating; Drain cover; Stair treads.

We are able to provide a full range of steel grating series and accessories.

---PRODUCTION PROCESS ---

---PROJECT CASE ---

Grating Standard Packing Method: 1. Bandage and Paperboard: Generally applies to neat steel plate; 2. Screw Locking Method: Use 4 screw rods through the aperture of the steel grid, for high strength; 3. Steel Pallet: Traditional export packing.

---COMPANY PROFILE ---

--- EXHIBITION PHOTOS ---

--- F A Q ---

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

--- RELATED PRODUCTS ---

| Perforated Metal Sheet | Grip Strut | Wire Mesh |

| MORE >> | MORE >> | MORE >> |