- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Classification temperature:

-

1500C

-

Working temperature:

-

1350C

-

Usage:

-

Industrial Kiln Furnace

-

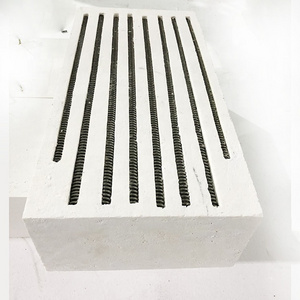

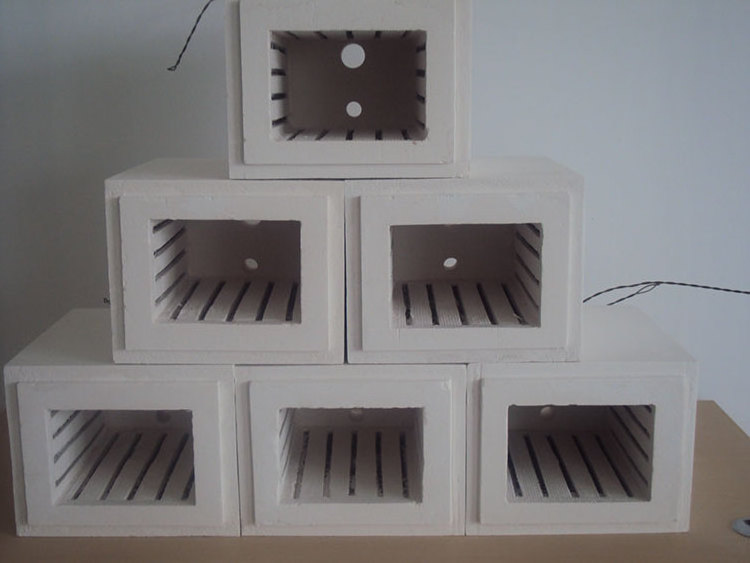

Heating element:

-

Resistance Wire/Sic/Mosi2

-

Chamber Size:

-

customized

-

Application:

-

Lab Muffle Furnace chamber

-

Certificate:

-

ROHS

-

Color:

-

White

-

Material:

-

Alumina ceramic fiber

-

Character:

-

Excellent Thermal Shock Resistance

Quick Details

-

Warranty:

-

not available

-

Brand Name:

-

SYN

-

Model Number:

-

SYN-H1500BTF

-

Place of Origin:

-

Henan, China

-

Classification temperature:

-

1500C

-

Working temperature:

-

1350C

-

Usage:

-

Industrial Kiln Furnace

-

Heating element:

-

Resistance Wire/Sic/Mosi2

-

Chamber Size:

-

customized

-

Application:

-

Lab Muffle Furnace chamber

-

Certificate:

-

ROHS

-

Color:

-

White

-

Material:

-

Alumina ceramic fiber

-

Character:

-

Excellent Thermal Shock Resistance

heater can be made into various shapes and sizes to meet the demands of the industrial production process.

|

Type

|

|

SYN-1260Y

|

SYN-

1400Y

|

SYN-

1500Y

|

SYN-

1600Y

|

SYN-

1700Y

|

SYN-

1800Y

|

|

|

Classicfication temperature(℃)

|

|

1260

|

1400

|

1500

|

1600

|

1700

|

1800

|

|

|

Work temperature(℃)

|

|

1000

|

1200

|

1350

|

1500

|

1600

|

1700

|

|

|

Color

|

|

White

|

White

|

White

|

White

|

White

|

White

|

|

|

Density(kg/m³)

|

|

250-400

|

250-400

|

300-400

|

400

|

350-400

|

400-500

|

|

|

Thermal conductivity

( w/mk) |

1000℃

|

0.23

|

0.23

|

0.23

|

0.17

|

0.19

|

0.24

|

|

|

|

1200℃

|

-

|

-

|

0.25

|

0.23

|

0.25

|

0.28

|

|

|

Shrinkage (%)

|

|

1100℃*

24h

-2.2

|

1200℃*

24h

-2

|

1400℃*

24h

-1.5

|

1500℃*

24h

-0.5

|

1600℃*

24h

-0.5

|

1500℃*

24h

-0.20

|

|

Note: We can manufacture according to your requirement and drawing,and we can also offer design with production.

Features:

1. Accurate Dimension

2. Low thermal conductivity,low thermal capacity

3. Excellent thermal stability and thermal shock resistance

4. High strength and excellent machinability

5. Excellent sound absorption capacity

6. Good fire-resistance,high thermal insulation

7. Excellent wind corrosion resistance,long service life

8. Produced to individual customer requirement

9. Easy cutting and installation

Henan Synthe Corporation was founded in January 2013, as a separate and independent

company to better serve its customers. SYNTHE was engaged in the design, development, manufacture, and sales of high-temperature insulation, vacuum-formed ceramic fiber heaters, diffusion heaters, and high-quality thermal processing equipment, all custom

designed to meet your thermal requirements. Our products are used around the world in the most demanding heat treatment, lab thermal furnaces, dental, photovoltaic solar, semiconductor and environmental protection applications, temperature ranges from

room temperature 20°C ( 68°F) to 1800°C ( 3272°F). For over ten years in the industry, we have been a problem-solver working with our customers to resolve their thermal management problems.

The company has obtained the "High-tech enterprise", "Private enterprise of technology", and other awards successively. Currently, it has eight new utility patents, and two other patents of invention and eight other new utility patents are in the process of application.

1.Is your company accepting customization?

We have our own factory and excellent technical team, and we accept OEM service.

2.Shall you offer samples?

Yes, we can offer the client samples in stock.

3.How to solve the quality problems?

If the products do not conform to customer samples or have quality problems, our company will be responsible to make compensation for it.

4. What is the delivery time?

15-25 days after receiving deposit

A: If we have the size you need in stock. we will send them 2-3 days, if you order crucible need to produce, the delivery time is about 10-25days.

5. What's your regular practice concerning terms of payment?

A: Payment terms :T/T 30%-50% deposit after order confirm ,the balance after goods ready before shipping or L/C, or Western Union for small amount. Or PAYPAL.