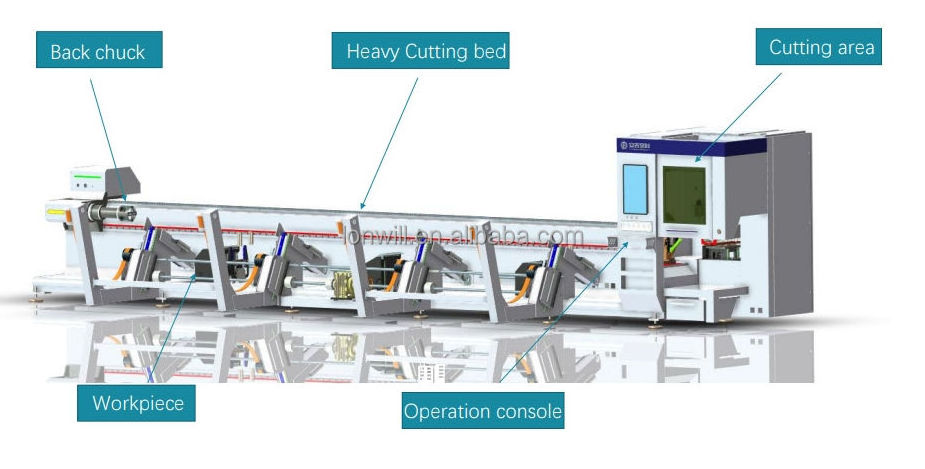

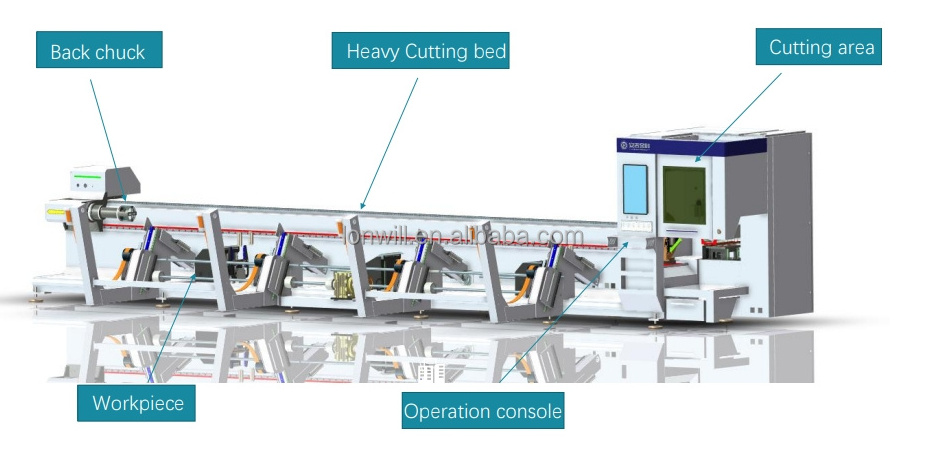

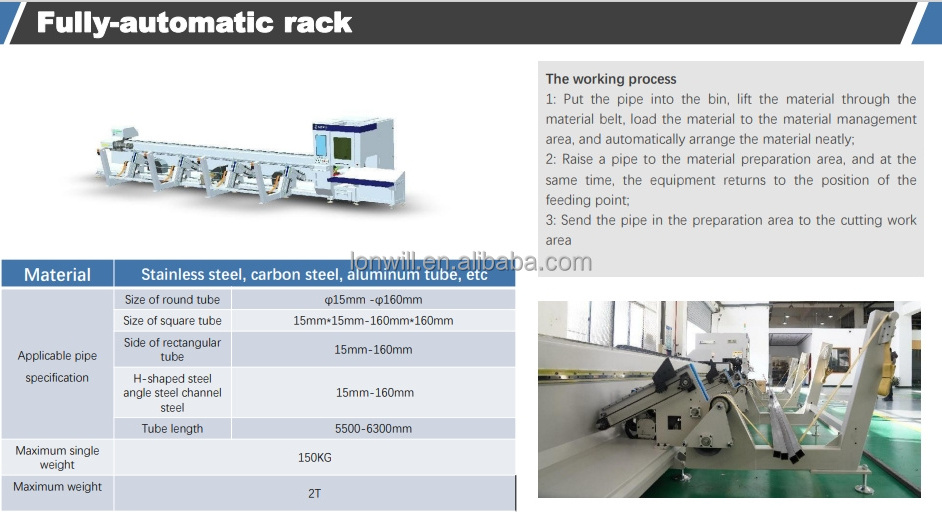

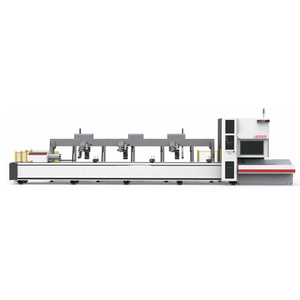

1: Put the pipe into the bin, lift the material through the material belt, load the material to the material management area, and automatically arrange the material neatly;

2: Raise a pipe to the material preparation area, and at the same time, the equipment returns to the position of the feeding point;

3: Send the pipe in the preparation area to the cutting work area