- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HUWEI

-

Fabric Weight:

-

75-150 KG

-

Material Capabilities:

-

Knitted and woven fabric, no-woven, medical gauze

-

Machine size(mm:

-

2600*1800*950 mm

-

Double lay height (mm):

-

180-230(optional)

-

Spreading method:

-

single or zig zag

-

Fabric roll:

-

rolling fabric/pieces fabric

-

After sales Service Provided:

-

Spare Parts

Quick Details

-

Applicable Industries:

-

TEXTILE INDUSTRY, Garments & Textiles

-

Weight (KG):

-

550

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HUWEI

-

Fabric Weight:

-

75-150 KG

-

Material Capabilities:

-

Knitted and woven fabric, no-woven, medical gauze

-

Machine size(mm:

-

2600*1800*950 mm

-

Double lay height (mm):

-

180-230(optional)

-

Spreading method:

-

single or zig zag

-

Fabric roll:

-

rolling fabric/pieces fabric

-

After sales Service Provided:

-

Spare Parts

Product Description

|

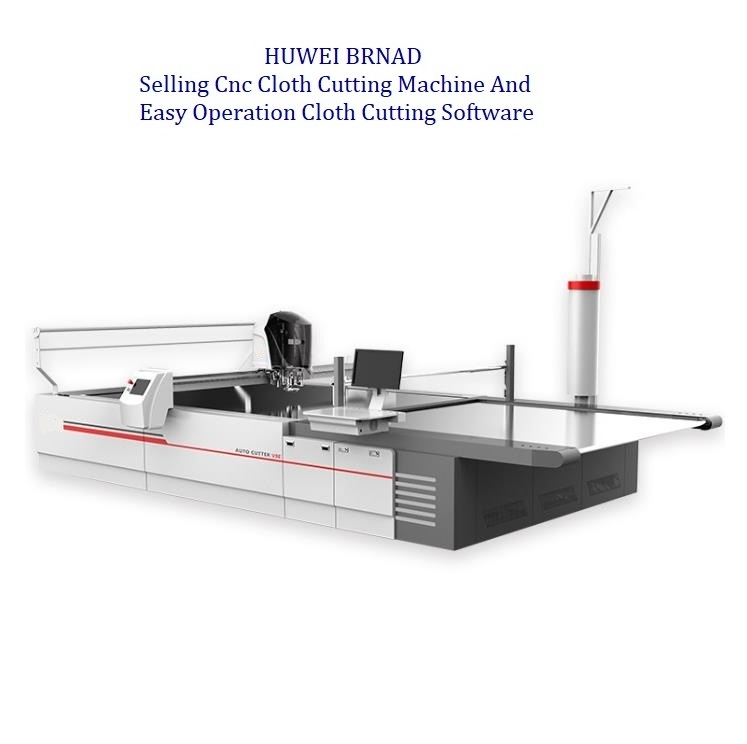

Automatic cnc fabric cutting laying machine:

|

|

|

|

|

|

|

||||||

|

Model

|

P9E III -2025

|

Y8S-190

|

Y8S-210

|

Y6S-160

|

Y6S-190

|

Y6S-210

|

||||||

|

Voltage

|

5 P/380 V/50 HZ

|

|

|

|

|

|

||||||

|

Motor power

|

30 kw

|

|

|

|

|

|

||||||

|

Max cutting height

|

9 cm

|

|

|

|

|

|

||||||

|

Working speed

|

0-100 m/min

|

|

|

|

|

|

||||||

|

Sharpening method

|

Belt sharpening

|

|

|

|

|

|

||||||

|

Cloth Width

|

160 M

|

190 CM

|

200 CM

|

250 CM

|

190 CM

|

260 CM

|

||||||

|

Cutting widow length

|

200 cm

|

|

250 cm

|

330 cm

|

|

customized

|

||||||

|

Unload Converyor length

|

200 cm

|

|

250 cm

|

330 cm

|

|

customozed

|

||||||

|

Machine W

eight

|

4200 kg/max

|

|

|

|

|

|

||||||

|

Air flow

|

200 L/min

|

|

|

|

|

|

||||||

Automatic fabric laying cutting machine:

Application area:

* This machine is suitable for all kinds of cutting,elastic fabrics ,milk silk,swimsuit,jean ,underwear,fleece,raincoat and fiber fabrics.

* This machine is suitable for all kinds of cutting,elastic fabrics ,milk silk,swimsuit,jean ,underwear,fleece,raincoat and fiber fabrics.

Main Component:

*Intelligent grinding system

*Efficient head cutting

*Intelligent

*Vacuum pressure system

*With air-through window technology

* Computer interaction system

Features:

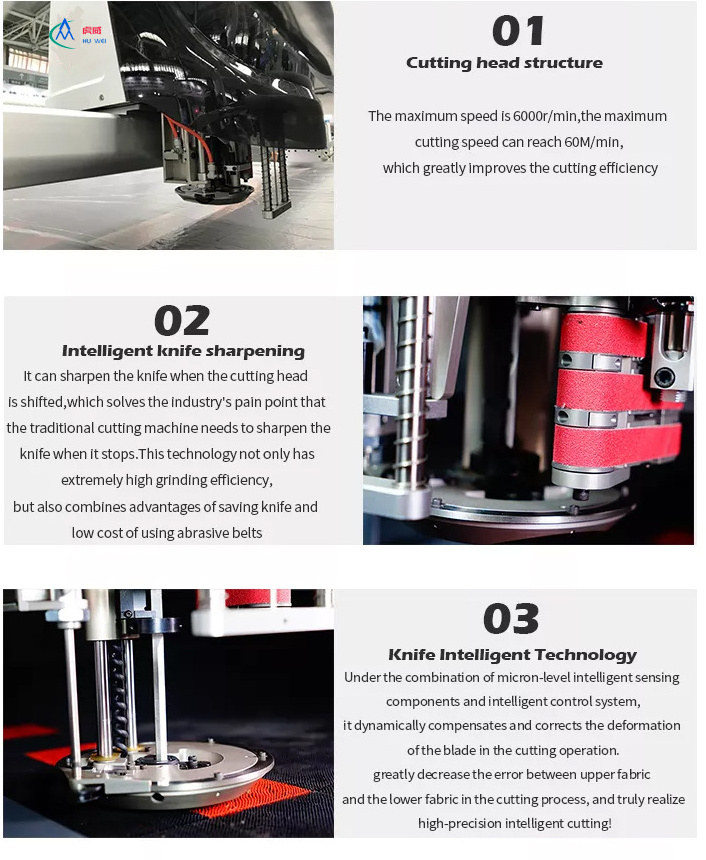

*Cutting edge intelligent technology: With the combination of micro-level intelligent sensing components and intelligent control system, it can dynamically compensate and correct the cutting edge deformation during cutting operations, which greatly improves the quality of the upper and lower fabrics during the cutting process. error, and truly realize high-precision intelligent cutting!

*

Punching device: driven by servo motor, high penetrating power and high stability;

*

High-efficiency cutting head: the maximum speed is 6000 r/min, and the maximum cutting speed can reach 60 m/min, which greatly improves the cutting efficiency;

*

Smart Grinding: Grinding can be performed when the cutting head is moving, which solves the industry pain point that traditional cutting machines need to be stopped to grind. This technology not only has extremely high grinding efficiency, but also takes into account the advantages of labor saving and low cost of abrasive belt use;

*

XY strip transmission structure: using precision-machined high-fit strip, high transmission efficiency, high precision, low noise, suitable for high-speed cutting operations;

*

Stable mechanical and electrical system: One-piece molding machine with extremely high rigidity; equipped with intelligent servo control system, using the original components of internationally renowned electrical brands, stable and efficient.

Hot Searches