Our company cooperates with Japan's NADIC Co., Ltd. in research and development.

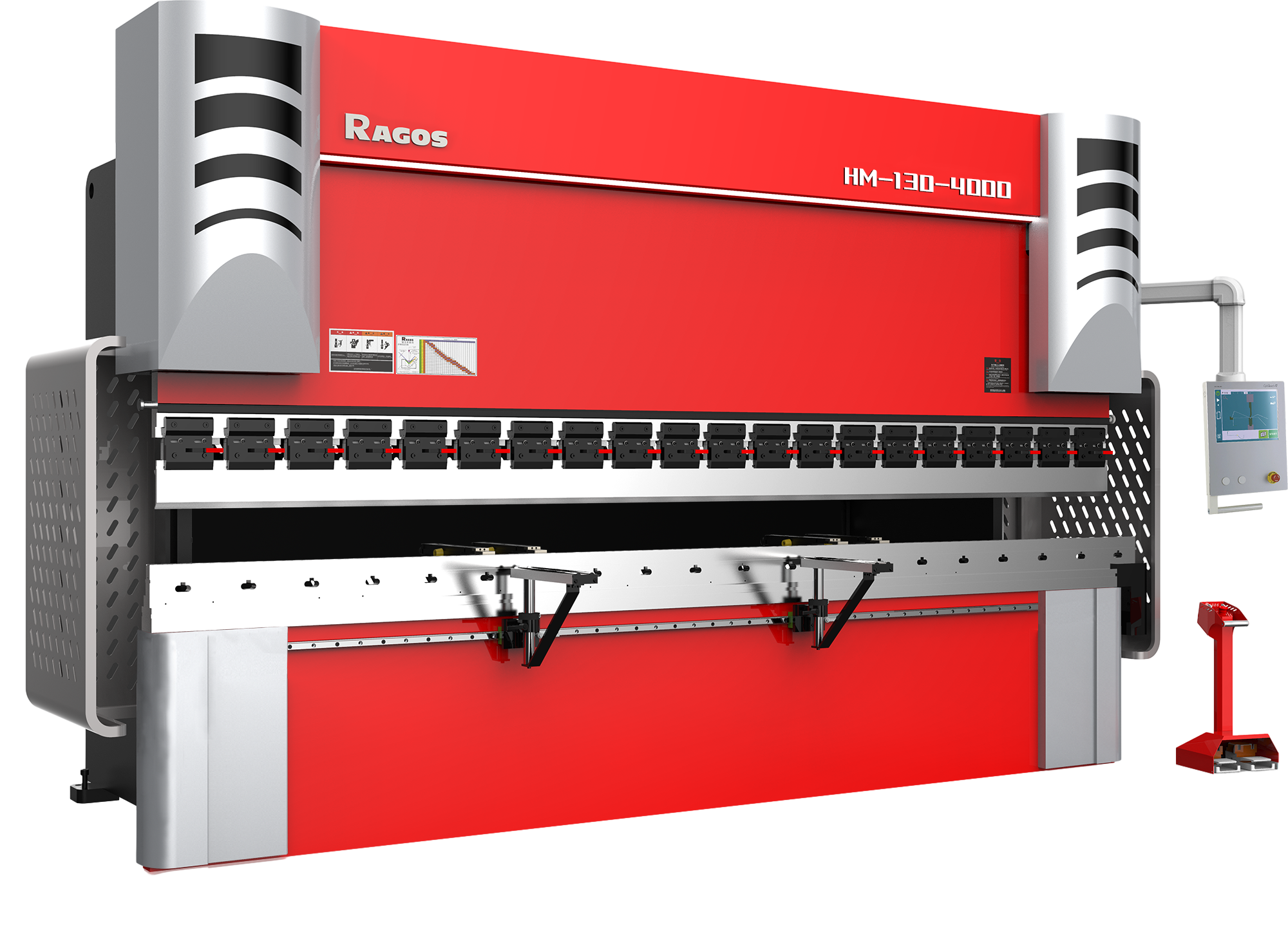

RANGOS is committed to building the most professional service team,Quality management team, superb industry experience.