- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

OD1.0

-

Specification:

-

OD3.2*ID1.5mm

-

Length:

-

1000mm

-

Thickness:

-

customized

-

Standard:

-

ISO10993

-

Product name:

-

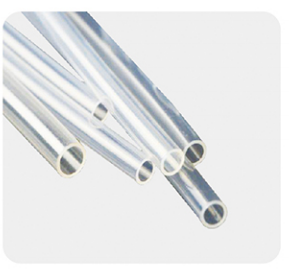

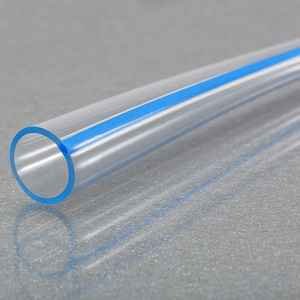

fluoroplastic capillary tubing

-

Color:

-

Black or white

-

Density:

-

1.3 g/m3

-

Tensile strength:

-

90 MPa

-

Distortion temperature:

-

315℃

-

Flammable level:

-

UL94 V-0

-

Rockwell hardness:

-

118 HRR

-

Application:

-

lab or analytical equipment

-

Certificate:

-

ROHS,REACH,ISO10993

Quick Details

-

Processing Service:

-

Cutting, Negotiable, Flanging,expanding,sealding the head, welding

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ChinaPEEK

-

Model Number:

-

OD1.0

-

Specification:

-

OD3.2*ID1.5mm

-

Length:

-

1000mm

-

Thickness:

-

customized

-

Standard:

-

ISO10993

-

Product name:

-

fluoroplastic capillary tubing

-

Color:

-

Black or white

-

Density:

-

1.3 g/m3

-

Tensile strength:

-

90 MPa

-

Distortion temperature:

-

315℃

-

Flammable level:

-

UL94 V-0

-

Rockwell hardness:

-

118 HRR

-

Application:

-

lab or analytical equipment

-

Certificate:

-

ROHS,REACH,ISO10993

FAQ

RFQ about PEEK material

Question 1. What is PEEK ?

PEEK(Poly ether ether ketone) is the most well known and important member of the PAEK(Poly aryl ether ketone) group. This high-performance polymer material combines high-termperature resistance,good wear, and excellent mechanical properties.

For instance, the glass transition temperature of PEEK is around 143 °C (289 °F) ,and melts around 343 °C (662 °F). The carbon fiber filled PEEK or glass fiber PEEK material have a useful operating temperature of up to 250 °C (482 °F).

PEEK material is the best comprehensive performance of special engineering plastics. PEEK shows excellent overall performance due to its large amount of benezene ring structure in its molecule. At present, PEEK material made by Junhua PEEK is widely used in petroleum, food processing,semiconductor, texitile machinery,automotive,medical device,and aerospace industries.

Question 2. Which type of PEEK material is better for my product designing ?

I. PEEK5600G(unfilled PEEK or natural PEEK) advantage

PEEK5600G is one of unfilled or natural PEEK.It is a high performance, high temperature, semi crystalline thermoplastic material manufactured by JUNHUA PEEK. Outstanding chemical resistance and a high operating temperature (up to 250℃/480F) round out PEEK profile.PEEK plastic has excellent dimensional stability combined with high creep stability, ensuring the suitability of PEEK for the most sophisticated machined parts.

Besides, the unfilled black PEEK or black PEEK is also available.

II. PEEK5600CF30(30% carbon fiber filled PEEK ) advantage

PEEK5600CF30 is a 30% carbon filled PEEK material that is manufactured by JUNHUA PEEK. Its carbon fiber reinforcement supports the material a high level of rigidity. Carbon fiber reinforced PEEK demonstrates very high mechanical strength values.However,30% carbon fiber reinforced PEEK(PEEK5600CF30,1.4±0.02g/cm3)presents lower density than 30% glass fiber filled peek(PEEK5600GF30,1.5±0.02g/cm3).Besides,carbon fiber composites tend to be less abrasive than glass fibers while simultaneously resulting in improved wear and friction properties. The addition of carbon fibers also ensures a significantly higher level of heat conductivity which is also beneficial for increasing part life in sliding applications. Carbon filled PEEK has also an excellent resistance to hydrolysis in boiling water and super heated steam.

III. PEEK5600GF30( 30% glass fiber filled PEEK) advantage

Compared with unfilled PEEK(PEEK5600G),this 30% glass fiber reinforced PEEK material(PEEK5600GF30) exhibits increased mechanical strength and high rigidity.Plus, improved creep strength and dimensional stability are delivered by the 30% glass fiber filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.PEEK5600GF30 is widely used in the buyer cases, which has a marked compressive strength requirement on the product designing.

IV. PEEK5600LF30( HPV PEEK or bearing grade PEEK) advantage

PEEK5600LF30 black is developed especially for bearing and sliding applications. HPV PEEK is based on a PEEK polymer that has been modified with 10% each of PTFE, graphite and carbon fibres. It combines the properties of a high-grade matrix material with special, wear-improving additives. Compared to PEEK modifications(like PEEK5600GF30,PEEK5600CF30),PEEK5600LF30 black has the lowest coefficient of friction, and shows higher wear resistance. Furthermore, a comparatively higher dimensional stability under thermal load is delivered.

V. Can do you manufacture the customized PEEK?

Yes, we make the customized size or shape of PEEK products.Like irregular PEEK plate, PEEK tube made by JUNHUA PEEK, in order to meet the buyer`s new product requiremnet on less PEEK material cost.

In addition, different color of PEEK material we make to meet the buyer`s new project demand. Different polymer material filed to add the speical performance of PEEK product, and the like.

VI. Do you make the OEM / ODM PEEK materials or PEEK products ?

Yes, JUNHUA PEEK provides the suggestions for material selection,cost accounting, product design, process selection, mold design and manufacturing to help you complete the product quick design, manufacturing and procurement process. You tell us your PEEK product designing requirement, we provide you the One-stop PEEK solutions service.

Question 3. Why JUNHUA PEEK ?

JUNHUA PEEK is the premier PEEK product manufacture in China.This manufacture is a one-stop PEEK production solution partner for worldwide buyers.

I. Junhua

Hot Searches