- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1000*910*810

-

Weight:

-

150 KG

-

Product name:

-

centrifugal concentrator

-

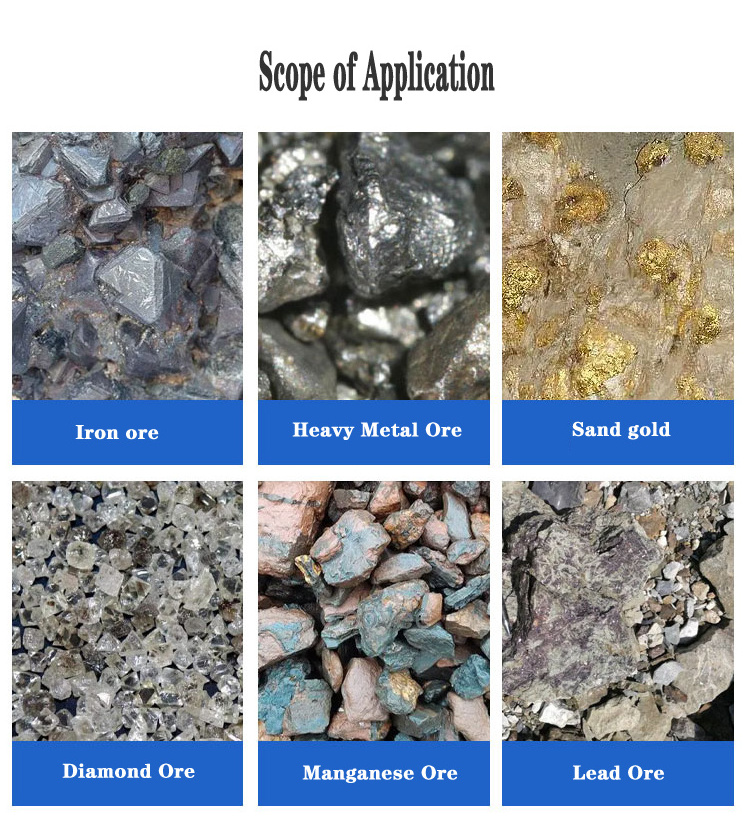

Application:

-

Separation of mineral processing materials

-

Key words:

-

Centrifugal gold concentrator

-

Processed materials:

-

Gold, Silver, Copper

-

Advantage:

-

High Separator Rate 96-99.99%

-

Color:

-

Customizable

-

Capacity:

-

3-7 m³/h

-

Packaging:

-

According to customer requirements

-

Factory Visit:

-

Welcomed Warmly

-

After sale service:

-

Life-long Service

Quick Details

-

Production Capacity:

-

90%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Qishun

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1000*910*810

-

Weight:

-

150 KG

-

Product name:

-

centrifugal concentrator

-

Application:

-

Separation of mineral processing materials

-

Key words:

-

Centrifugal gold concentrator

-

Processed materials:

-

Gold, Silver, Copper

-

Advantage:

-

High Separator Rate 96-99.99%

-

Color:

-

Customizable

-

Capacity:

-

3-7 m³/h

-

Packaging:

-

According to customer requirements

-

Factory Visit:

-

Welcomed Warmly

-

After sale service:

-

Life-long Service

Video Description

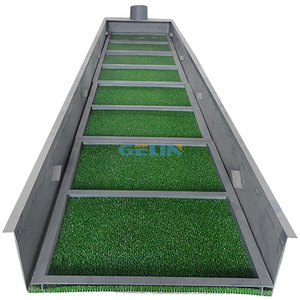

Centrifugal Concentrator

The vertical centrifuge was developed according to the characteristics of alluvial gold production in China. It is especially suitable for the selection of alluvial gold. It also has good separation effect on other large density minerals, such as tungsten sand and tin sand. It can replace the chute and manual panning, improve the separation efficiency and reduce labor intensity. It has been widely used in field geological investigation, small gold mining and separation, laboratory heavy sand separation and other fields. Many combinations have been used in gold dredgers at home and abroad.

Product Parameters

|

Disc diameter(mm)

|

600

|

|

Working speed (r/min)

|

100-180

|

|

Power (kw)

|

1.1

|

|

Dimension(mm)

|

1000*800

|

|

Weight(kg)

|

155

|

|

Drive

|

AC motor. Diesel generator

|

|

Feeding time (min)

|

20-40

|

|

Feeding size(mm)

|

3

|

|

Capacity(m³/h)

|

3-7

|

Product structure

Product Show

Workflow

Working Principle

Mineral particles of different densities and particle sizes are subjected to friction, centrifugal force, gravity, media buoyancy, hydrodynamic force, media resistance and separation tank force in the inclined inclined incline. The upward movement produces stratification, which is then discharged by hydrodynamic and other functions. It becomes concentrate and tailings.

Loading and delivery

Packing method

1.Small parts in wooden boxes

2. Large parts packed in plastic film

3.The whole big machine is packed in a container

Sea/air shipment

or by any means requested by the customer

Successful case

Associated Equipment

FAQ

1. Are you manufacture or trading company?

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Hot Searches