- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Xiangxin

-

Model Number:

-

304 304l

-

Name:

-

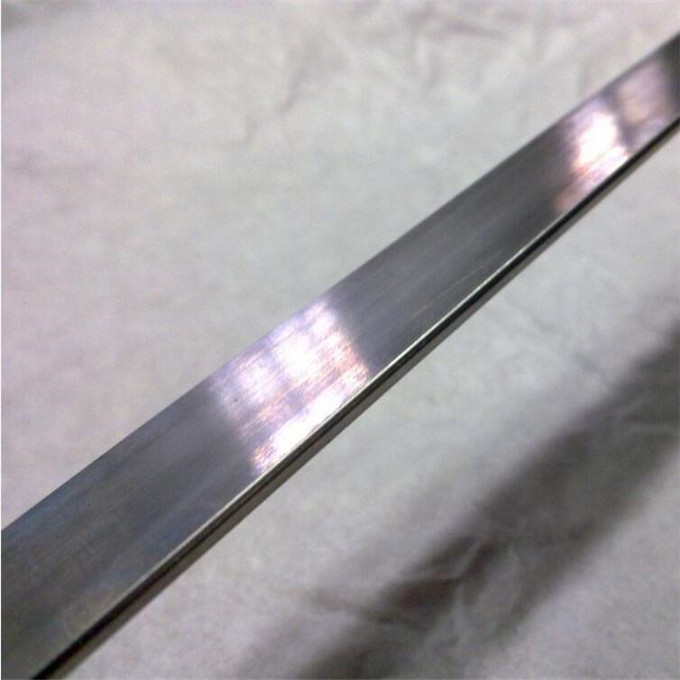

Stainless steel flat bar 304 304l

-

Original:

-

China

-

Surface finish:

-

Black, pickled, bright, ground as per customers' requirement

-

Width:

-

3-500mm

-

Brand:

-

lisco tisco baosteel posco

-

Advantage:

-

5 discounts

-

Finishing:

-

Hot rolled, cold drawn, hot forged

-

Sample:

-

Free

-

MOQ:

-

1Ton

-

Payment Term:

-

L/C T/T D/P D/A

-

Certification:

-

ISO

Quick Details

-

Grade:

-

300 Series

-

Tolerance:

-

±1%

-

Application:

-

Construction

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Xiangxin

-

Model Number:

-

304 304l

-

Name:

-

Stainless steel flat bar 304 304l

-

Original:

-

China

-

Surface finish:

-

Black, pickled, bright, ground as per customers' requirement

-

Width:

-

3-500mm

-

Brand:

-

lisco tisco baosteel posco

-

Advantage:

-

5 discounts

-

Finishing:

-

Hot rolled, cold drawn, hot forged

-

Sample:

-

Free

-

MOQ:

-

1Ton

-

Payment Term:

-

L/C T/T D/P D/A

-

Certification:

-

ISO

- Delivery 5 or 7 workdays in Stock

-

Material Grade:304 304l

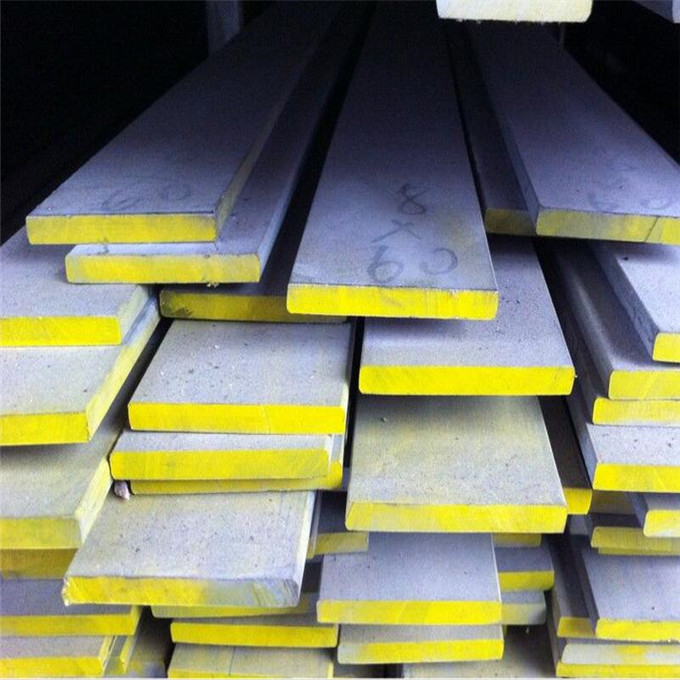

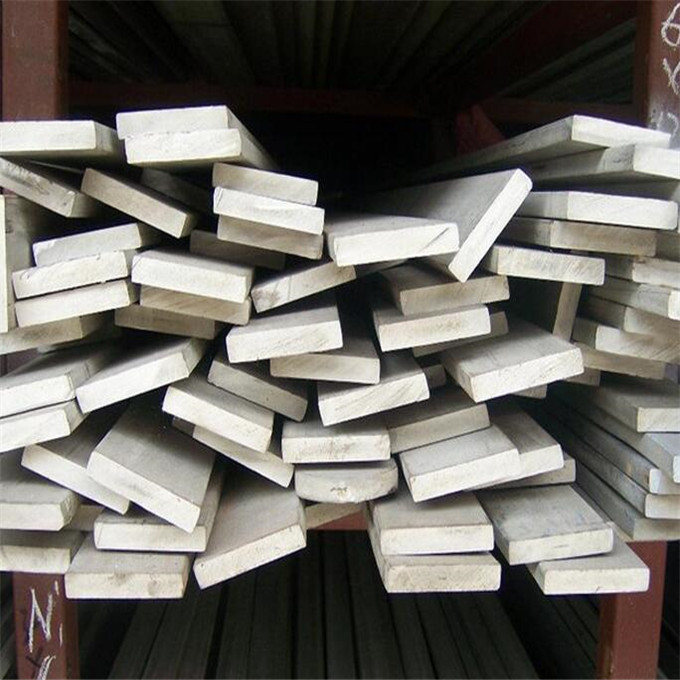

- Width:3-500mm;Thickness:0.3-120mm;Length:1000-6000m;

- Original :Tisco

- Payment:T/T, L/C, D/P,D/A

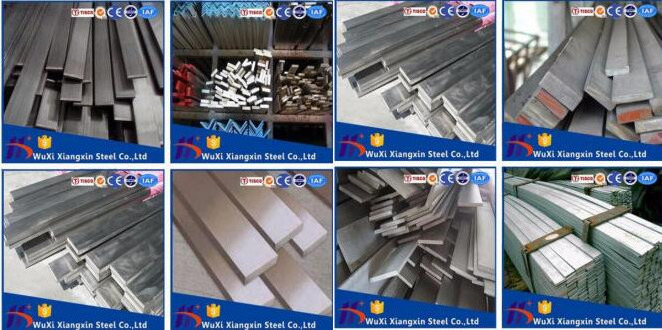

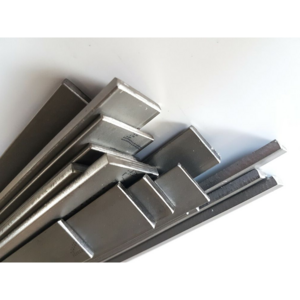

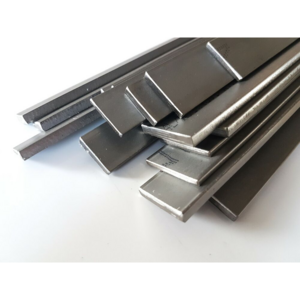

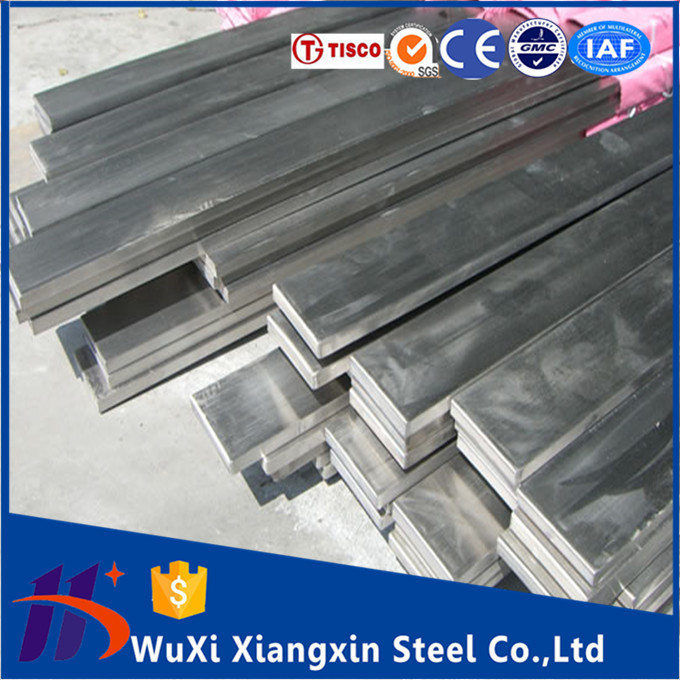

1.Specifications about stainless steel Flat Bar

| ITEM |

Stainless Steel Flats bar

|

| Brand | RONSCO,BAOSTEEL, JISCO, TISCO, etc. |

| Size | Width 3-500mm;Thickness0.3-120mm;Length:1000-600mm(or as your request) |

| Surface | Black, pickled, bright, ground as per customers' requirement |

| Finish | Hot rolled, cold drawn, hot forged |

| Material |

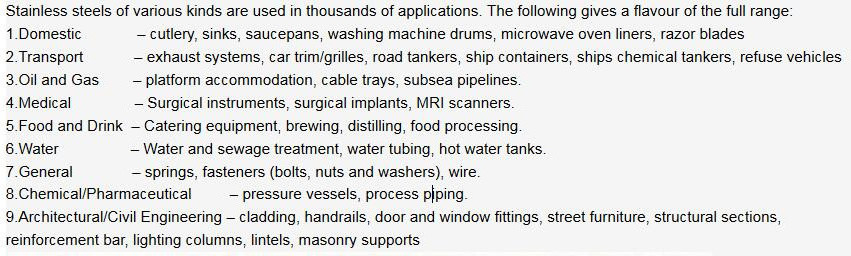

201.202.301.302.304.304L.310S.316.316L.321.420.309S.2205.2507.2520.430 .410. 630,631,904L ect. Or Customized |

| Standard | GB, AISI, ASTM, ASME, EN, BS, DIN, JIS |

| Application |

Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

| Package | Standard export sea-worthy packing or customized |

| Delivery Terms | FOB,CFR,CIF,CNF etc. |

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0.15 |

≤0.75 |

5.5-7.5 | ≤0.06 | ≤0.03 | 3.5-5.5 | 16.0-18.0 | - |

| 202 | ≤0.15 | ≤1.0 | 7.5-10.0 | ≤0.06 | ≤0.03 | 4.-6.0 | 17.0-19.0 | - |

| 301 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤0.03 | 19.0-22.0 | 24.0-26.0 | - |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 |

12.0-15.0 |

16.0-18.0 | 2.0-3.0 |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 9.0-13.0 | 17.0-19.0 | - |

| 630 | ≤0.07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0-28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.80 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤0.03 | 0.19-0.22 | 0.24-0.26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.12 | ≤0.75 | ≤1.0 | ≤0.040 | ≤0.03 | ≤0.60 | 16.0-18.0 |

- |

1.with plastic cap to protect both ends

2.weaving bag wrapped outside the pipe

3.then pack into wooden case.

delivery detail:3or 5workdays since received the deposit of L/C draft.

2.Related Products

200 Series 300 Series 400 series 900series 2000 Series

Main Product

| Stainless steel round square rectangular pipe | ||||

| Stainless Steel circle | stainless steel strips | |||

Available Surface

3.Stainless steel maintenance:

(1) Regular clea ning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

4. Related certificate