- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

200 - 700 mm

-

Ejector Stroke(mm):

-

150 mm

-

Ejector Force(kN):

-

40 kN

-

Theoretical Shot Volume(cm³):

-

700 cm³

-

Injection Rate (g/s):

-

100 g/s

-

Injection Weight (g):

-

300 g

-

Screw diameter (mm):

-

150 mm

-

Weight (KG):

-

9000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

700 mm

-

Model Number:

-

TYM-W5555

-

Brand Name:

-

TYM

-

Power (kW):

-

13.2 kW

-

Machine Dimensions(m):

-

4.3*1.5*2.1m

-

Machine weight:

-

4.5T

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

500mm

-

Distance between Tie Bars(Height)(mm):

-

500mm

-

Plasticizing Capacity(g/s):

-

165

-

Mold Height(mm):

-

200 - 700 mm

-

Ejector Stroke(mm):

-

150 mm

-

Ejector Force(kN):

-

40 kN

-

Theoretical Shot Volume(cm³):

-

700 cm³

-

Injection Rate (g/s):

-

100 g/s

-

Injection Weight (g):

-

300 g

-

Screw diameter (mm):

-

150 mm

-

Weight (KG):

-

9000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

700 mm

-

Model Number:

-

TYM-W5555

-

Brand Name:

-

TYM

-

Power (kW):

-

13.2 kW

-

Machine Dimensions(m):

-

4.3*1.5*2.1m

-

Machine weight:

-

4.5T

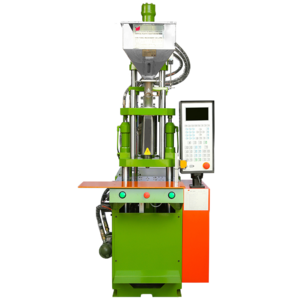

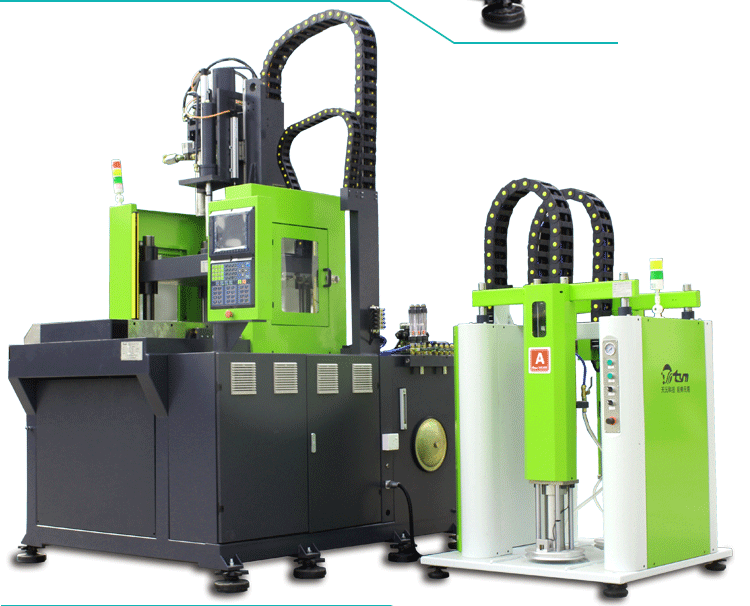

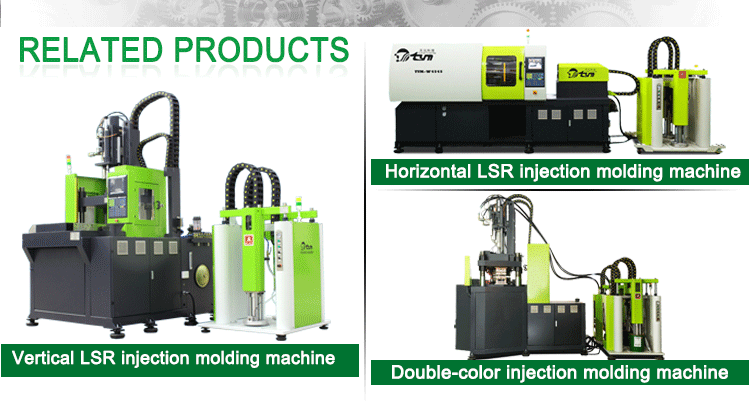

Vertical Liquid Silicone Rubber (LSR) injection molding machine

The vertical machine will open and close the mold in the vertical direction. The double slide plate can be installed with one upper mold and two lower molds. it can cooperate with the double station operation to improve the production efficiency, and is more suitable for the production of rubber coated products of silica gel package inserts.

The main feature of the vertical LSR molding machine:

A.Newly-optimized integrated all-in-one design.

B.Double slide and double station operation to improve production efficiency.

B.Double slide and double station operation to improve production efficiency.

C.Small screw is easy to disassemble and clean, with less material waste

D.Guide rail type sliding plate has fast speed and long service life.

|

ITEM

|

DESCRIPTION

|

UNIT

|

TYM-L4048

|

TYM-L5058

|

TYM-L6068

|

TYM-L7078

|

|

Injection Unit

|

Shot Volume

|

g

|

165

|

165

|

300

|

300

|

|

|

Injection Rate

|

g/s

|

100

|

100

|

100

|

100

|

|

|

Injection Pressure

|

Kg/cm2

|

700

|

700

|

700

|

700

|

|

Clamping Unit

|

Clamping Force

|

T

|

95T

|

130T

|

150T

|

150T

|

|

Clamping Unit

|

Opening Stroke

|

mm

|

250-550

|

400-700

|

400-700

|

600-900

|

|

|

Tie-Bars Space

|

mm

|

400*480

|

500*580

|

600*680

|

700*780

|

|

|

Ejection Force

|

T

|

4

|

4

|

4

|

4

|

|

|

Ejection Stroke

|

mm

|

150

|

150

|

150

|

150

|

|

|

Pump Pressure

|

Mpa

|

20

|

20

|

20

|

20

|

|

Others

|

Motor Power

|

KW

|

13.2

|

13.2

|

13.2

|

13.2

|

|

|

Machine Weight

|

T

|

4.7

|

5.3

|

5.6

|

7.5

|

|

|

Machine Dimension

|

m

|

2.2*1.6*3.5

|

2.4*1.7*3.5

|

2.7*1.8*3.6

|

3.2*1.9*3.8

|

Hot Searches