- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

1-20mm

-

Control Software:

-

CypCut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

pioneer cnc

-

Weight (KG):

-

6000 KG

-

Effective cutting area:

-

1500mmx3000mm

-

Laser power:

-

1000-8000w

-

Laser generator:

-

Raycus

-

Laser head:

-

WSX or Raytools

-

Control system:

-

CypCut

-

Cutting materials:

-

Stainless Steel Carbon Steel Sheet

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Driving system:

-

Japan Yaskawa Servo Motor

-

Cutting speed:

-

100m/min

-

Acceleration:

-

1G

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

100m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

1-20mm

-

Control Software:

-

CypCut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

pioneer cnc

-

Weight (KG):

-

6000 KG

-

Effective cutting area:

-

1500mmx3000mm

-

Laser power:

-

1000-8000w

-

Laser generator:

-

Raycus

-

Laser head:

-

WSX or Raytools

-

Control system:

-

CypCut

-

Cutting materials:

-

Stainless Steel Carbon Steel Sheet

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Driving system:

-

Japan Yaskawa Servo Motor

-

Cutting speed:

-

100m/min

-

Acceleration:

-

1G

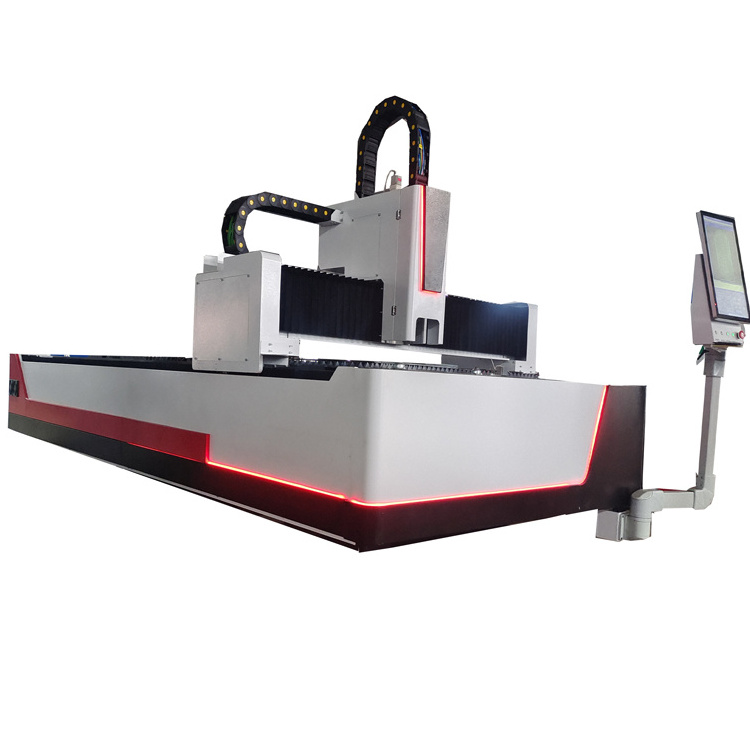

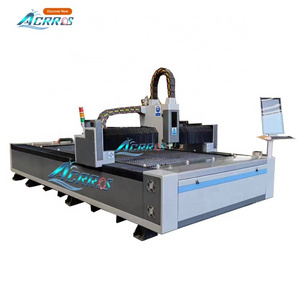

4000w iron aluminum copper laser cutter 1530 1560 cnc metal fiber laser cutting machine

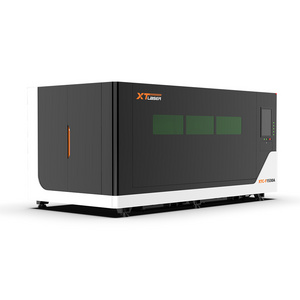

Enclosed laser cutting machine with exchange table

The series of pioneer PF-3015D laser cutting machine offers power ranges between 2000W to 15000W. One of the most efficient machine technologies for rapid sheet metal cutting which can cut the thickness for 50mm or less.

1. Saving Material ---- CNC control, it can cut the material in different shapes, improve the utilization rate and reduce waste.

2.Easy Programme ----high accuracy, cut to shape without molding, smooth finish, eliminating the process for edge modification.

3. Save Investment for Molding ---- Laser cutting without molding, eliminating the cost for molding and repair, save time, resulting in less manufacturing cost, reduce the cost of goods sold, particularly suitable for processing parts in large-size.

4. Protecting Environment ---- working area for laser cutting is fully enclosed, low noise, is clean, safe, free of pollution, totally improve the working condition and environment.

Fiber Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

| laser power source range | 1000w-8000w |

| effective cutting area for plate steel | 3000mmx1500mm(can be customized) |

| Laser source brand | Raycus/MAX |

| Laser head | Raytools /WSX |

| Controller | CypCut |

| Acceleration speed | 2G |

| Positioning accuracy | ±0.03mm |

| Repeating positioning accuracy | ±0.015mm |

| Maximum moving speed | 100m/min |

1. High rigidity heavy chassis, reducing the vibration generated during the high-speed cutting process.

2.Gantry double drive structure, with imported Germany rack & gear transmission system, which improves the production efficiency.

3. High-performance cast aluminum guide rail, after infinite analysis, which accelerates the circular arc cutting speed.

4.High precision, fast speed, narrow slit, minimum heat-affected zone, smooth cut surface, and no burr.

5. The laser cutting head does not come into contact with the surface of the material and does not scratch the workpiece.

6. The slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is very small, and there is no mechanical deformation.

7. It has good processing flexibility, can process any pattern, and can cut pipes and other profiles.

8. Non-deformable cutting can be performed on materials of any hardness such as steel plates, stainless steel, aluminum alloy plates, and hard alloys.

Machine Body (Plate welding with stiffener inside,not square pipe weld frame)

1.Machines over 6 meters are welded with 16mm and 20mm steel plates. We promise that our customers' machine tools will not deform in ten years, and the quality is the best advertisement;

2.Effective cutting area 1500mmx3000mm/2000mmx6000mm/2500mmx6000mm(can be customized);

3.15T weight(20mm plate steel welding structure);

4.Germany IPG laser source,high photoelectric conversion efficiency,sound worldwide service network;

5.Germany Precitec autofocus head(LightCutter 2.0 or ProCutter 2.0),longer service time;

- --Pre-Sales Service

Free Pre-Sales Consulting / Free Sample Making

Speedy Laser offer 12 hours quick pre-sales response and free consulting. Any kind of technical support are available for users.

Free Sample Making is available.

Free Sample Testing is available.

We offer progressing solution design to all the distributor and users.

---After-sales Services

1. 3 year guarantee for main machine (People damaged are charged).

2. Full technical support\ by e-mail, call and video

3. Lifelong maintenance and spare parts supply.

4. Free design of fixtures as customers required.

5. Free training installation and operation for the staffs.