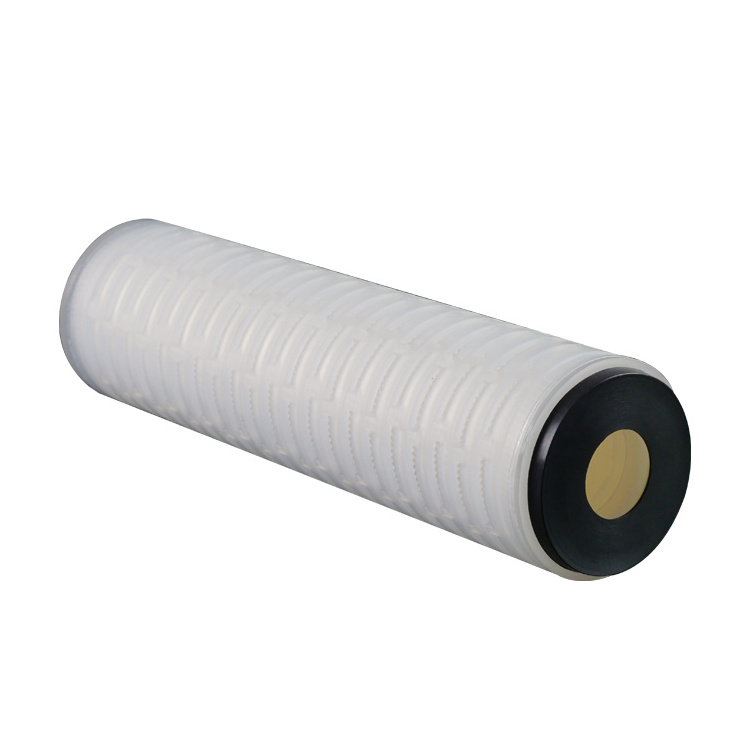

PP pleated filter cartridge deliver high efficiency and consistent filtration of fluids in a wide range of critical applications. They are constructed of pleated membrane filter media that provides removal of particles from 0.1 to 60um, the pore size is not affected by the vibration of

feeding pressure, due to its unique low differential pressure, high flow volume, excellent filtration microns. The high surface area ensures long service life and low initial pressure drops.

- Product Details

- {{item.text}}

Quick Details

-

Name:

-

pleated Filter Cartridge

-

Filter membrane material:

-

PP/PVDF/PTFE/PES/Nylon

-

Length:

-

5 / 10 / 20 / 30 / 40 / 50 / 60 inch

-

Conector:

-

Fin/222/226/215/DOE/Thread

-

Micron:

-

0.22/0.5/1/3/5/10/25/50/75/100/150

-

Sealing method:

-

Hot melting welding

-

Diameter:

-

70mm/OEM

-

Inner Core:

-

PP/SS/OEM

Quick Details

-

Weight (KG):

-

1

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM/ODM

-

Name:

-

pleated Filter Cartridge

-

Filter membrane material:

-

PP/PVDF/PTFE/PES/Nylon

-

Length:

-

5 / 10 / 20 / 30 / 40 / 50 / 60 inch

-

Conector:

-

Fin/222/226/215/DOE/Thread

-

Micron:

-

0.22/0.5/1/3/5/10/25/50/75/100/150

-

Sealing method:

-

Hot melting welding

-

Diameter:

-

70mm/OEM

-

Inner Core:

-

PP/SS/OEM

SOE 226/fin micro pore N66 folded candle filter 0.2 micron nylon membrane filter for mineral water filter treatment

Microporous pleated filter element, the main filter material is : Polypropylene, Hydrophobic PTFE, Hydrophilic PTFE,Polyether sulfone, Nylon, etc.

Most of the raw materials are imported from abroad.Pleated filter element is a kind of deep filtration filter,it is usuaslly used as liquid overheating,clarification, filtration and terminal filter.

It has the following characteristics: the superfine polypropylene fiber membrane as the filtration medium, low pressure differential, high flux, good filtration precision, lower economic cost.

The whole structure of polypropylene, end cover, housing and center pole adopts polypropylene material; It adopts the hot melt welding process, PP and PP melt bonding,without any binder.

It has wide range of chemical compatibility, and also has a series of pore size and form a variety of interface.Material: Pleated filter, Support layer, End-cover, Inside & Outside cylinder are polypropylene.

Welding: It adopts the uniquehot melting methods, no glue, no foreign body fall off.

Typical use: Pharmaceutical, Food, Chemical, Electronics, Environmental protection, etc.

Microporous membrane pleated filter cartridge main features: High interception rate, high liquidity, low pressure differential and a wide range of chemical compatibility;

The production process adopts unique hot melting process technology, no any adhesive, no foreign body release.

It can meet the food,beverage, beer, chemical, pharmaceutical and other industries production requirements.

Polypropylene microporous membrane filter

PTFE membrane pleated filter

Hydrophobic PTFE filter

The filter medium is Hydrophobic PTFE microporous membrane filter: Strong hydrophobicity,

High holding rate, excellent chemical resistance and thermal stability, good strength, impact resistance of the forward & reverse pressure.

Hydrophilic PTFE filter

The filter element medium for hydrphilic PTFE microporous membrane filter: The hydrophilic stability, high entrapment rate, excellent chemical resistance thermal stability, good strength, impact resistance of the forward & reverse pressure.

Polyether Sulphone PES Pleated Filter

The PES pleated filter cartridge is constructed of imported polyethersulfone(PES) membrane media and non-woven support materials.The material of cage core and end caps are polypropylene.Adapters are thermally welded with media without using any glue, no any pollution. The PES filter cartridge is ideally suited for critical prefiltration in sterilizing applications and final filtration in a broad range of demanding non-sterile application, the inherently hydrophilic membrane contains no surfactant or wetting agents, which results in good filtration and flow rates.

Nylon N66 pleated membrane filter cartridge

The filter medium is hydrophilic nylon microporous membrane filter, It is composed by nylon membrane and the polypropylene support material hot melting, it is no dung, also applicable for the strict chemical and pharmaceutical industries.

PVDF pleated cartridge filter

The PVDF pleated cartridge filter is constructed of imported natural hydrophobic polyvinylenedifluoride(PVDF) membrane media and non-woven support materials. The adaptors are thermally welded with media without using any glue, no any pollution.

High filtration microns, high flow rate, better hydrophobicity, sterilization at high temperature as well as chemical resistance. It is widely used in gas or liquid pre-filtration and widely used in final filtration.

Jumbo pleated membrane filter cartridge

The big jumbo pleated filter cartridge is constructed of deep polypropylene membrane, melt blown polypropylene, hydrophilic PES & PTFE. The non-woven support materials. This filter cartridges design increased the effective filtration area, not only can reduct the filter cartridges quantity, but also it can make the smaller housing size. Big flow rate and long service life, lower cost and human cost. The size is divided into 2 kinds of size: 83mm diameter & 131mm diameter. Adaptors are thermally welded with media without using any glue, no any pollution and droppings. Clean & stable, each filter cartridge has passed strict testing by 100% integrity.

|

Product Name

|

|

|

|

||

|

Filtration media

|

PP/PTFE/PES/PVDF/Nylon

|

|

|

||

|

Support material

|

Polypropylene

|

|

|

||

|

Core & Structural components

|

Polypropylene

|

|

|

||

|

Inner core

|

PP/Stainless steel

|

|

|

||

|

Packing method

|

Polybag/Vacuum

|

|

|

||

|

Filtration precision

|

0.1μm, 0.2μm, 0.45μm, 0.65μm,0.8μm,1μm,2μm,3μm,5μm,10μm,20μm,25μm,30μm,50μm

|

|

|

||

|

Length

|

2.5", 5". 10", 20", 30", 40", 50", 60", OEM

|

|

|

||

|

Adaptor

|

215/222/226/Fin/Flat/Thread/OEM

|

|

|

||

|

Sealing method

|

Hot melting welding

|

|

|

||

|

Sealing gasket & O-ring material

|

Silicone rubber; Nitrile butadiene rubber, EPDM, Fluorine rubber.

|

|

|

||

|

Effect filtration area

|

≥0.6m²

|

|

|

||

|

Filter cartridge diameter

|

69mm

|

|

|

||

|

Max. working temperature

|

PP: 88℃,0.27Mpa

PTFE: 80℃, 0.173Mpa

PES: 85℃, 0.28Mpa

PVDF: 80℃, 0.173Mpa

Nylon: 49℃, 0.21Mpa

|

|

|

||

|

Max. positive differential pressure

|

0.42Mpa (25℃)

|

|

|

||

|

Max. back pressure differential pressure

|

0.28Mpa (25℃)

|

|

|

||

|

Sterilization conditions

|

121℃ 30min

|

|

|

||

|

Applications

|

Chemical industry; Organic solvents; Various of alcohols; Chemical reagents filtration; Sterile tank breathing apparatus; Pharmaceutical industry; Food industry; Electronic industry; RO water treatment; Medical liquid filtration;

|

|

|

||

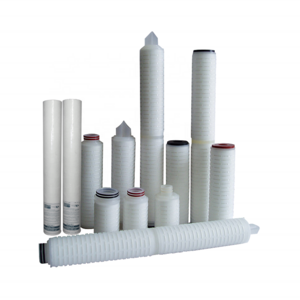

DOE opened pleated filter

The membrane's micron rating is optional. Options to order for this site include 0.03 to 0.45 microns in 10" to 40" length with either.

OEM customized size filter

Different length & variety end cap are optional.

Different end caps pleated filter

SDouble Open End (DOE), 222 or 226 end configurations, all come standard with EPDM/PTFE/SILICONE/TEFLON seals.

Container for shipment

Container for shipment