1 1. Advanced structure, good sealing, the kiln head is sealed by the shell, and the kiln tail adopts the axial contact seal

which ensures the sealing is reliable.

2. Easy to install and maintain; large kiln equipped with the auxiliary drive to meet the needs of installation and

maintenance.

4.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

225kw

-

Dimension(L*W*H):

-

as requested

-

Weight:

-

47.5 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certificate:

-

ISO9001:2008,CE

-

Type:

-

Cement kiln

-

Application:

-

Cement,construction

-

Capacity:

-

0.9--42 t/h

-

Energy:

-

Saving

-

Structure:

-

Reasonable

-

Installation:

-

Full technology support

-

Name:

-

Dry process industrial cement lime kiln:

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongxing

-

Voltage:

-

220, 380V

-

Power:

-

225kw

-

Dimension(L*W*H):

-

as requested

-

Weight:

-

47.5 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certificate:

-

ISO9001:2008,CE

-

Type:

-

Cement kiln

-

Application:

-

Cement,construction

-

Capacity:

-

0.9--42 t/h

-

Energy:

-

Saving

-

Structure:

-

Reasonable

-

Installation:

-

Full technology support

-

Name:

-

Dry process industrial cement lime kiln:

Product Description

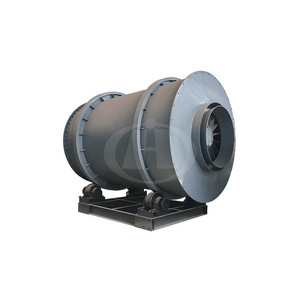

Rotary kilns work by processing material in a rotating drum at high temperatures for a specified retention time to cause a

physical change or chemical reaction in the material being processed. The kiln is set at a slight slope to assist in moving

material through the drum. According to the material types to be processed, the rotary kiln can be divided into cement kiln,

metallurgical chemistry kiln, and limestone kiln.

physical change or chemical reaction in the material being processed. The kiln is set at a slight slope to assist in moving

material through the drum. According to the material types to be processed, the rotary kiln can be divided into cement kiln,

metallurgical chemistry kiln, and limestone kiln.

|

PRODUCT NAME

|

ROTARY kiln

|

|

CAPACITY

|

100-600tph

|

|

DRYING STONE

|

cement and lime etc

|

|

COLOR

|

CUSTOMERSIZED

|

|

MANUFACTURER

|

HENAN HONGXING

|

|

ORIGIN

|

HENAN,CHINA

|

PRODUCT FEATURE

The rotary kiln with large unit volume, long furnace life, stable operation, high heat transfer efficiency, and low heat

consumption.

The rotary kilns offer a robust and reliable design that delivers the benefits of low resource consumption and high

operational reliability.

consumption.

consumption.

The rotary kilns offer a robust and reliable design that delivers the benefits of low resource consumption and high

operational reliability.

consumption.

Product Paramenters

Company Introduction

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of

heavey duty industrial workshops.covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters

heavey duty industrial workshops.covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters

Packing&Shipping

Ways of packing:1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Delivery

1.Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc. and train shipping is also available.

2.We will remind you before boat arrival

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Delivery

1.Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc. and train shipping is also available.

2.We will remind you before boat arrival

After Sales Service

Pre-sale service

Provide quality technical consulting services, understand customer needs, according to the actual situation of

production capacity, site design reasonable, economic supporting program.

production capacity, site design reasonable, economic supporting program.

Sale service

Provide door-to-door installation services, professional technical team door-to-door installation, commissioning

equipment, guidance and training personnel, ensure efficient operation of the machine.

equipment, guidance and training personnel, ensure efficient operation of the machine.

After-sales service

Provide regular return visit service to help users optimize equipment maintenance and timely analyze and

solve the equipment problems feedback from customers

solve the equipment problems feedback from customers

FAQ

What about the quality of your products?

Our products are manufactured strictly in accordance with the national and international standard, and we always test every

equipment before the delivery.

Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the

policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards

business ".

In order to help you get a suitable machine and provide you a preferential quotation,

Pls kindly provide the following information:

1. What's the materials to process?

2. What's the feature of the materials? Like density, moisture degree,input particle size and out put particle size.

3. What's your capacity per hour?

4. What's material for the machine?

5.What's the machine you want to buy?A single machine or a production line.

Our products are manufactured strictly in accordance with the national and international standard, and we always test every

equipment before the delivery.

Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the

policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards

business ".

In order to help you get a suitable machine and provide you a preferential quotation,

Pls kindly provide the following information:

1. What's the materials to process?

2. What's the feature of the materials? Like density, moisture degree,input particle size and out put particle size.

3. What's your capacity per hour?

4. What's material for the machine?

5.What's the machine you want to buy?A single machine or a production line.

Working Site

Related Products

Hot Searches