- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Atcera

-

Product name:

-

Ceramic Substrate

-

Shape:

-

As Drawing Requests

-

Working temperature:

-

Max 1600℃

-

Compressive Strength:

-

>2068 MPa

-

Density:

-

3.7

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Hunan, China

-

Model Number:

-

Atcera

-

Brand Name:

-

Atcera

-

Product name:

-

Ceramic Substrate

-

Shape:

-

As Drawing Requests

-

Working temperature:

-

Max 1600℃

-

Compressive Strength:

-

>2068 MPa

-

Density:

-

3.7

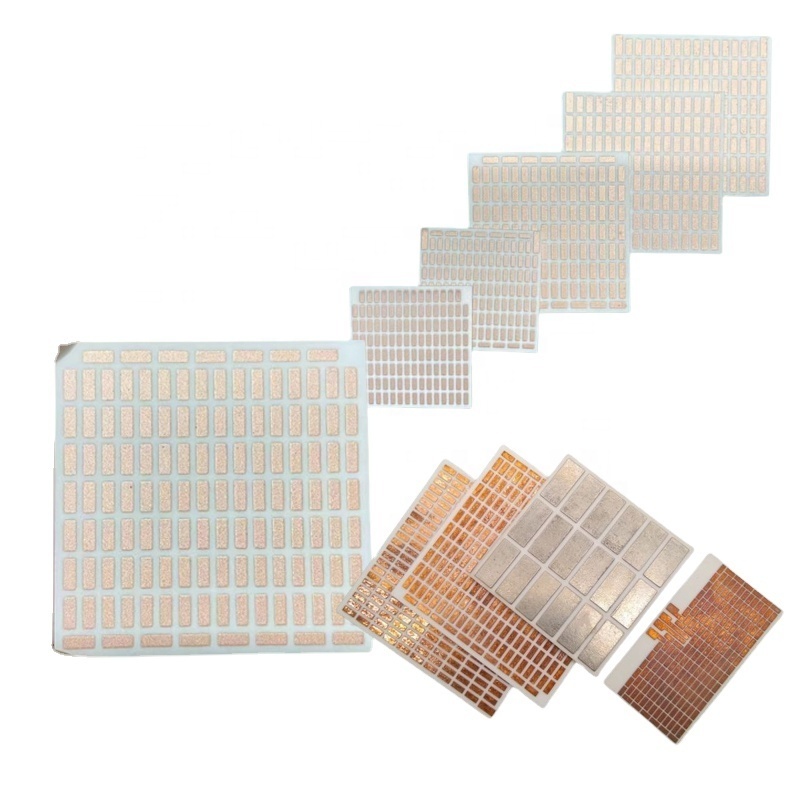

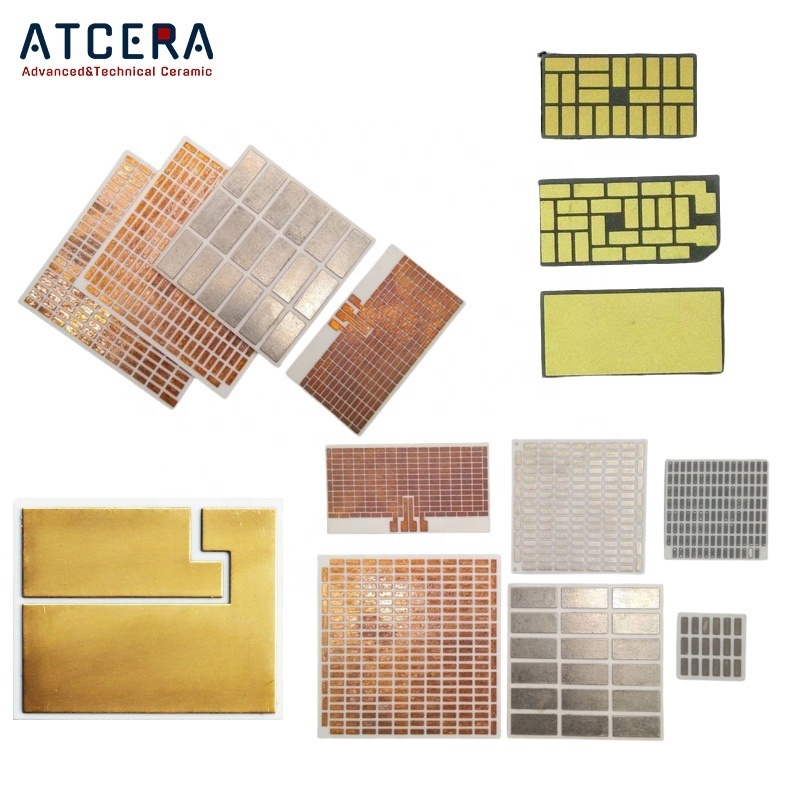

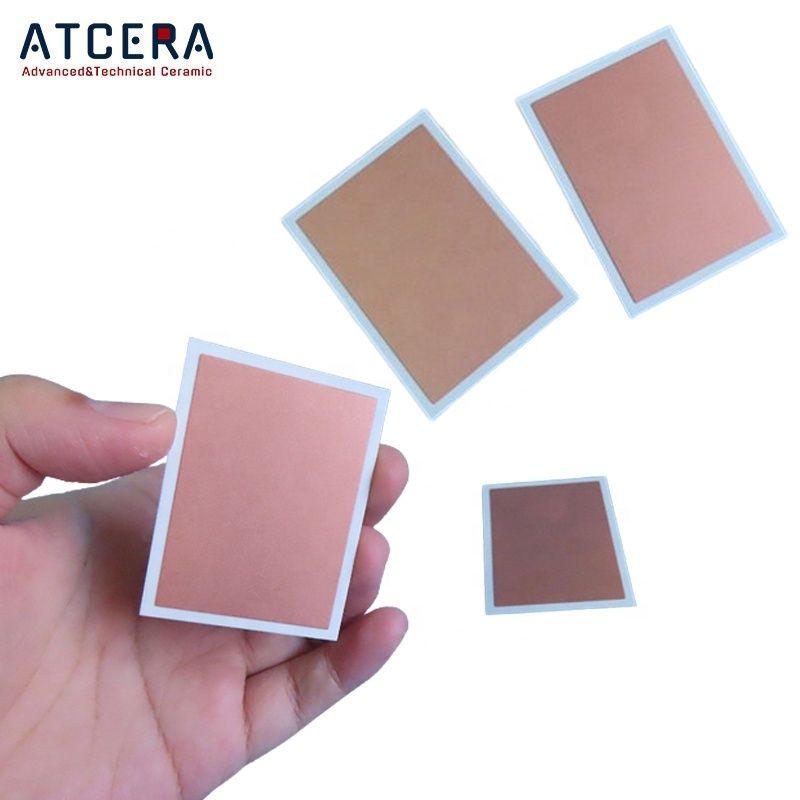

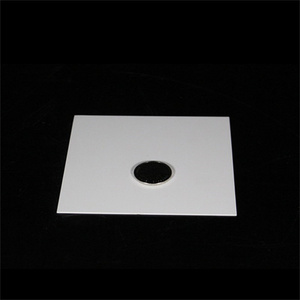

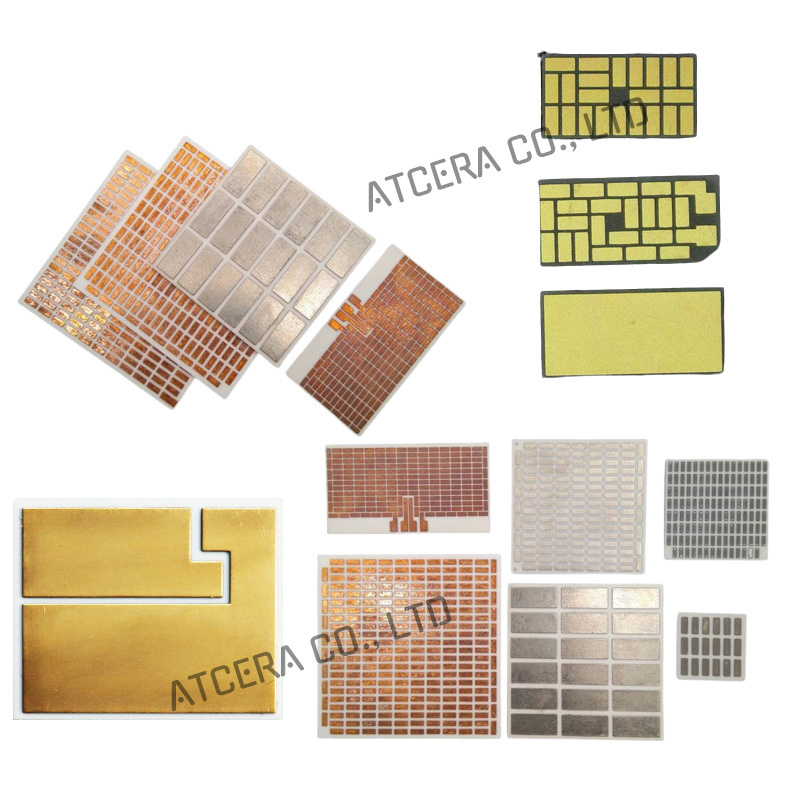

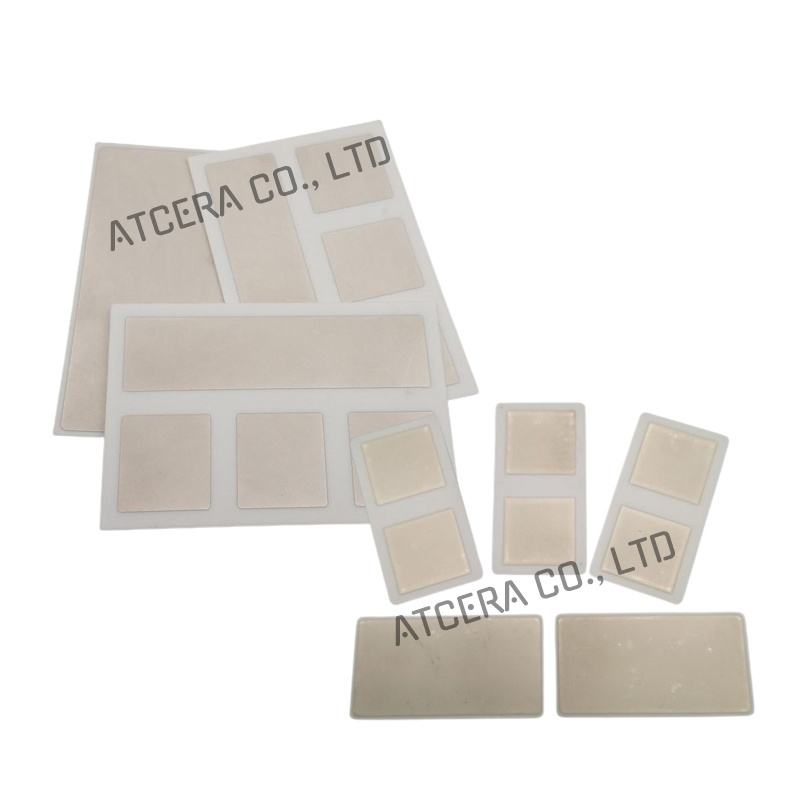

DBC substates is used to produce electronic devices such as resistor card, surface mount devices, hybrid integrated circuits and sensors by silk Screen printing technology and following process drying/curing, firing, and laser trimming of resistors. The finished super-thin DBC substrate has excellent electrical isolation,high thermal conductivity, fine solderability and high bonding strength.

As a new and high capability substrate, DBC substrates have been used widely in electric power and electronicindustry. ln

addition, all products can be nickel plating or gold plating. We can according to customer's requirements to customizedthe DBC of various sizes, specifications and have holes.

addition, all products can be nickel plating or gold plating. We can according to customer's requirements to customizedthe DBC of various sizes, specifications and have holes.

|

Alumina Ceramic Properties

|

|

95%Al2O3

|

99%Al2O3

|

99.5%Al2O3

|

||||

|

Item

|

Unit

|

Typical Values

|

|

|

||||

|

Physical Properties

|

|

|

|

|

||||

|

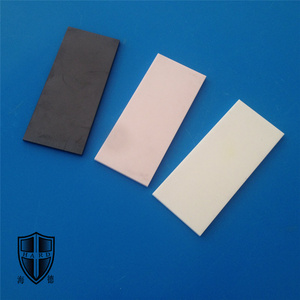

Color

|

|

White

|

Ivory

|

yellow

|

||||

|

Density

|

g/cm3

|

>3.6

|

3.89

|

3.96

|

||||

|

Alumina Content

|

%

|

95%

|

99%

|

99.50%

|

||||

|

Gas permeability

|

|

0

|

0

|

0

|

||||

|

Water Absorption

|

|

0

|

0

|

0

|

||||

|

Mechanical Properties

|

|

|

|

|

||||

|

MONS' Hardness

|

Grade

|

9

|

9

|

9

|

||||

|

Rockwell Hardness

|

HRA

|

≥85

|

≥89

|

≥89

|

||||

|

Vickers Hardness (Hv50)

|

Gpa(Kg/mm²)

|

15.7(1600)

|

15.7(1600)

|

15.7(1600)

|

||||

|

Flexural Strength(20°C)

|

psiX103

|

358

|

550

|

550

|

||||

|

Compressive Strength(20°C)

|

psiX103

|

2068(300)

|

2600(377)

|

2600(377)

|

||||

|

Modulus of Elasticity

|

Gpa

|

275

|

|

|

||||

|

Fracture Toughness(20°C)

|

Mpa.m3/2

|

4.3

|

5.6

|

6

|

||||

|

Thermal Properties

|

|

|

|

|

||||

|

Thermal Conductivity(20°C)

|

W(m.K)

|

16

|

30

|

30.4

|

||||

|

Thermal Expansion(25-1000°C)

|

1X10-6/℃

|

7.6

|

7.9

|

8.2

|

||||

|

Maximum Use Temperature

|

°C

|

1450

|

1600

|

1650

|

||||

|

Thermal shock resistance

|

°C

|

250

|

200

|

200

|

||||

|

Electronic Properties

|

|

|

|

|

||||

|

Volume resistivity(100°C)

|

Ohm/cm2

|

>1013

|

>1014

|

>1014

|

||||

|

Dielectric breakdown strength

|

KV/mm

|

8.7(220)

|

8.7(220)

|

8.7(220)

|

||||

|

Dielectric Constant

|

Er

|

9

|

9.7

|

9.7

|

||||

|

Dielectric constant (100MHz)

|

Er

|

9.5

|

|

|

||||

Hunan Atcera CO. Ltd. has been deeply engaged in the field of advanced ceramics for 12 years, and has production experience of more than 2000 precision ceramic products. We focus on the material of alumina ceramics, aluminum nitride ceramics, zirconia ceramics, silicon carbide ceramics, boron carbide ceramics, silicon nitride ceramics, boron nitride ceramics, quartz, etc., and aim to provide you with advanced ceramics one-stop service.We have been offering our products and services to our clients from more than 100 countries or regions.

Hot Searches