- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

ADA-SF

-

Brand Name:

-

PFM

-

Processing Service:

-

Weaving

-

Product name:

-

Titanium woven wire mesh for Trailer Flooring

-

Mesh count:

-

1-300mesh

-

Width:

-

1m , 1.22m

-

Length:

-

30m/roll

-

Keyword:

-

Wire mesh , wire cloth

Quick Details

-

Material:

-

Titanium

-

Type:

-

Wire Cloth

-

Application:

-

Filtering

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

ADA-SF

-

Brand Name:

-

PFM

-

Processing Service:

-

Weaving

-

Product name:

-

Titanium woven wire mesh for Trailer Flooring

-

Mesh count:

-

1-300mesh

-

Width:

-

1m , 1.22m

-

Length:

-

30m/roll

-

Keyword:

-

Wire mesh , wire cloth

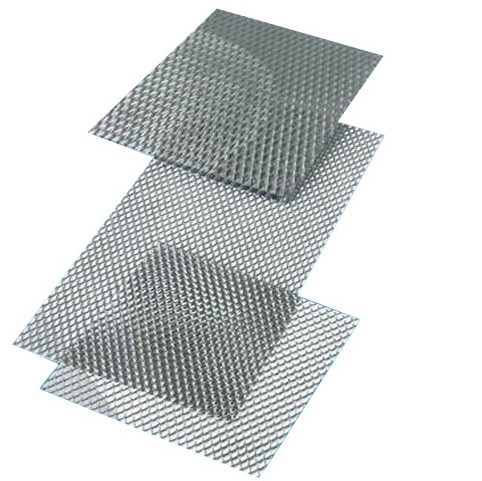

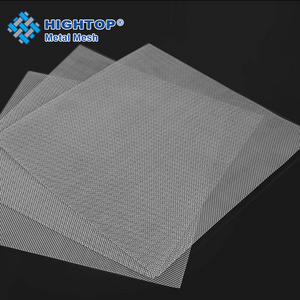

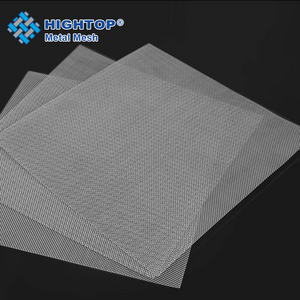

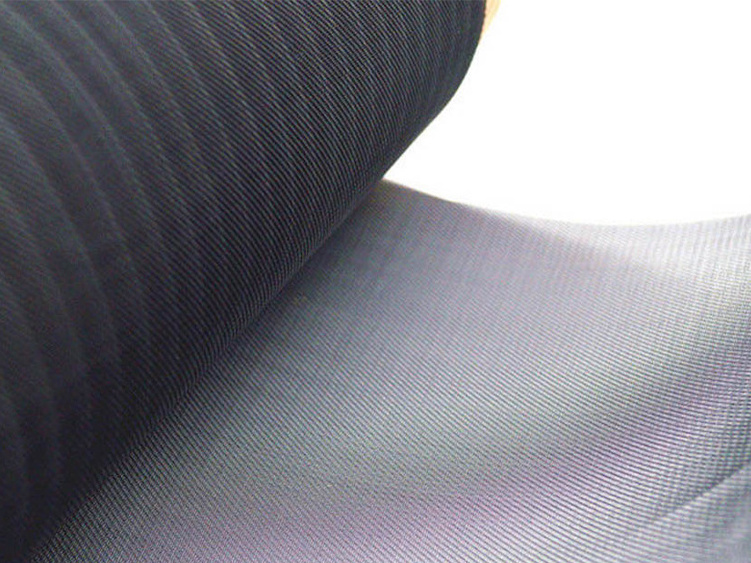

Titanium woven wire mesh for Trailer Flooring

1. Titanium woven wire mesh for Trailer Flooring Overview

Titanium woven wire mesh is a kind of products with outstanding corrosion resistance, low density and nontoxic performance. In the corrosion environment, the surface of high purity titanium mesh will form an oxidation film layer to protect wire mesh from being corroded. The layer is compact and inert, which has strong resistance to the corrosion. It has excellent corrosion resistant performance in below environment: Seawater, wet chlorine, chlorite and hypochlorite solution, nitric acid, chromic acid, metal chlorides and organic salts.

Because of the outstanding corrosion resistance, the titanium woven wire mesh has become the replacement material of nickel-free stainless steel wire mesh, aluminum wire mesh.

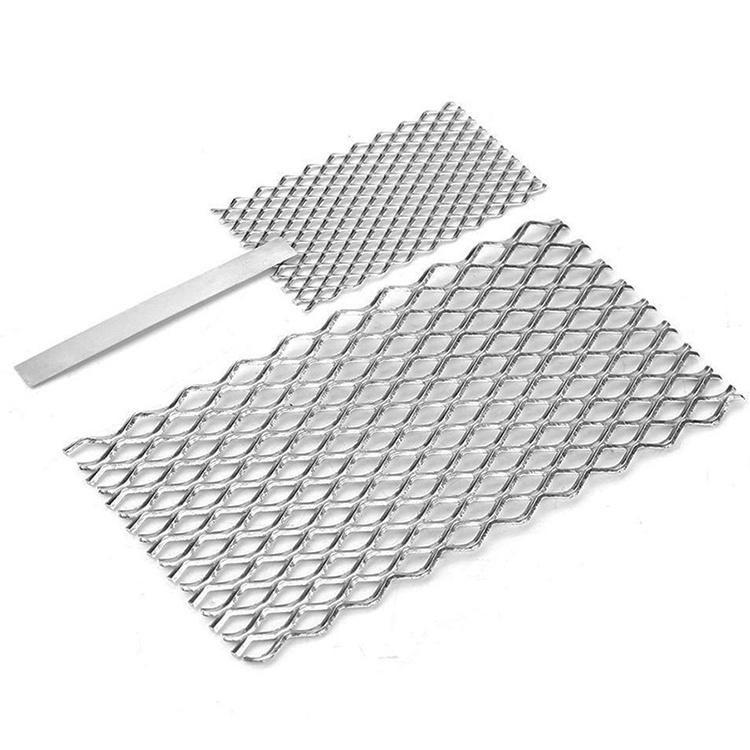

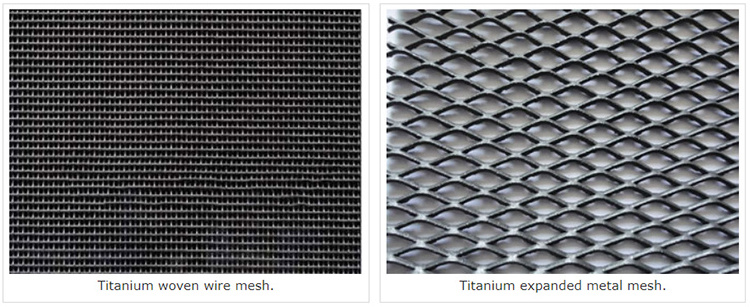

The titanium wire mesh has expanded wire mesh and perforated wire mesh types, which can be used for different applications.

2. Titanium woven wire mesh for Trailer Flooring T echnical Details

Specifications

Material grade: TA1, TA2 GR1, GR2, R50250.

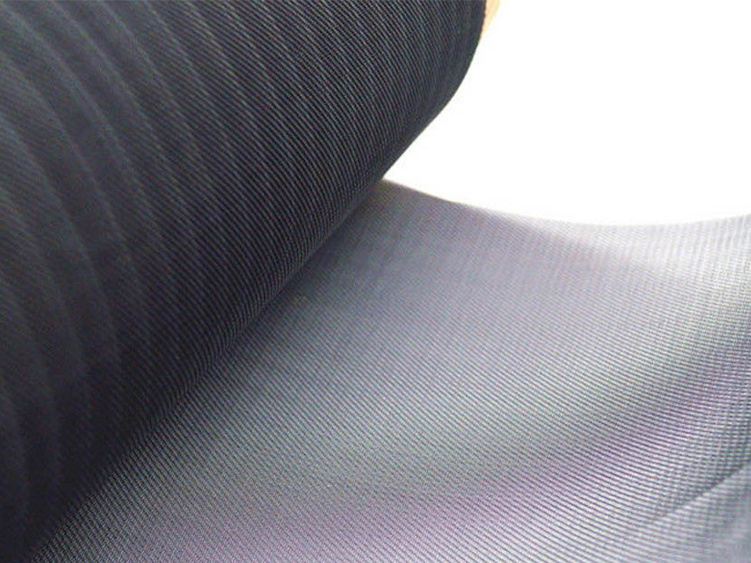

Weaving type: plain weave, twill weave and dutch weave.

Wire diameter: 0.002" - 0.035".

Mesh size: 4 mesh - 150 mesh.

Color: black or bright.

Titanium wire mesh specification:

| Mesh (Wires/ in.) | Wire diameter (in.) | Width of opening (in.) | Open area (%) |

| 4 × 4 | 0.032 | 0.218 | 76 |

| 4 × 4 | 0.035 | 0.215 | 74 |

| 6 × 6 | 0.032 | 0.135 | 65.6 |

| 7 × 7 | 0.025 | 0.118 | 68.2 |

| 8 × 8 | 0.032 | 0.093 | 55.4 |

| 9 × 9 | 0.032 | 0.079 | 50.6 |

| 10 × 10 | 0.035 | 0.065 | 42.3 |

| 10 × 10 | 0.03 | 0.07 | 49 |

| 10 × 10 | 0.025 | 0.075 | 56.3 |

| 12 × 12 | 0.011 | 0.0723 | 75.3 |

| 14 × 14 | 0.016 | 0.055 | 60.2 |

| 16 × 16 | 0.006 | 0.0565 | 81.7 |

| 18 × 18 | 0.01 | 0.046 | 67.4 |

| 18 × 18 | 0.011 | 0.0445 | 64.4 |

| 18 × 18 | 0.016 | 0.04 | 50.8 |

| 20 × 20 | 0.003 | 0.047 | 88.4 |

| 20 × 20 | 0.02 | 0.03 | 36 |

| 20 × 20 TW | 0.016 | 0.034 | 46.2 |

| 24 × 24 | 0.01 | 0.032 | 57.9 |

| 24 × 24 | 0.0118 | 0.0299 | 51.4 |

| 26 × 26 | 0.01 | 0.029 | 54.9 |

| 30 × 30 | 0.01 | 0.0233 | 49 |

| 32 × 32 | 0.01 | 0.021 | 46.5 |

| 35 × 35 | 0.008 | 0.0206 | 51.8 |

| 40 × 40 | 0.005 | 0.02 | 64 |

| 40 × 40 | 0.01 | 0.015 | 36 |

| 50 × 50 | 0.009 | 0.011 | 30.3 |

| 50 × 50 TW | 0.004 | 0.016 | 64 |

| 60 × 60 TW | 0.009 | 0.0077 | 21.3 |

| 90 × 90 | 0.004 | 0.0071 | 41 |

| 100 × 100 | 0.002 | 0.008 | 64 |

| 120 × 120 TW | 0.004 | 0.0043 | 27 |

| 150 × 150 TW | 0.0027 | 0.004 | 35.5 |

Titanium perforated metal specification range:

Opening size: 0.5mm to 50mm

Thickness: 0.1mm to 2mm

Sheet size: customized sizes available

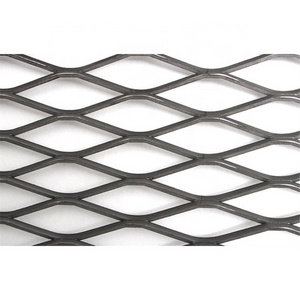

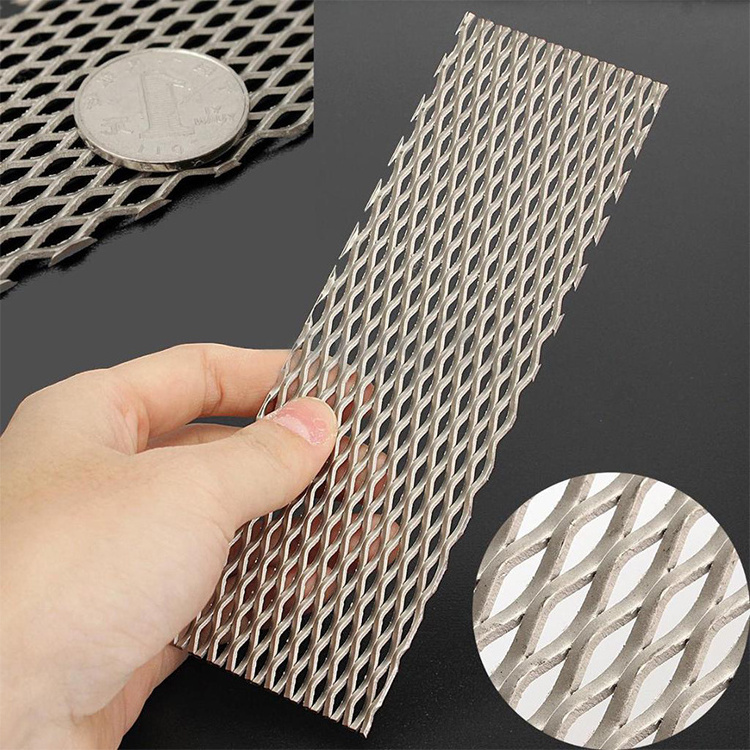

Titanium expanded metal specification range:

Opening size(LWD): 0.2mm to 10mm

Thickness: 0.1mm to 2mm

Sheet size: customized sizes available

3. Titanium woven wire mesh Features:

• Low density and high tensile strength.

•

Excellent Corrosion resistance.

•

High temperature resistance.

•

Outstanding filtration performance.

•

Good thermal property.

•

Acid and alkali resistance.

•

Nontoxic.

4. Titanium woven wire mesh Applications :

The titanium woven wire mesh can be used in various field in the below.

•

Shipbuilding.

•

Military industry

•

Chemical industry.

•

Mechanical industry.

•

Petroleum.

•

Pharmaceutics

•

Medicine.

•

Satellite and aerospace.

•

Environmental industry.

•

Electroplating industry.

•

Battery industry.

•

Surgery.

The titanium wire mesh has lots of usage:

•

Filtration. Chemical filter, mechanical filter, oil filter.

•

Electromagnetic shielding.

•

Desalination.

•

Skull repair and reconstruction.