- Product Details

- {{item.text}}

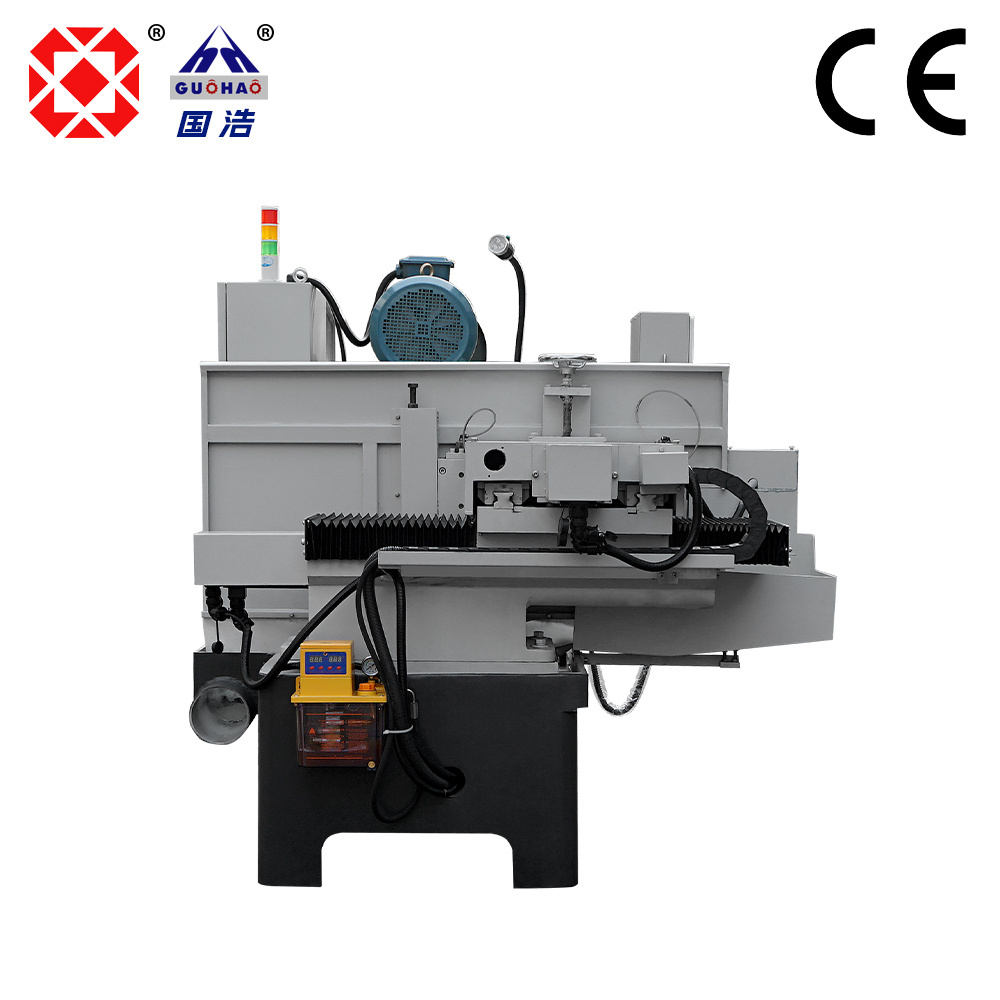

Quick Details

-

Brand Name:

-

GUOHAO MACHINE

-

Voltage:

-

380V 50HZ 3-PHASE

-

Dimension(L*W*H):

-

2100x1800x1800mm

-

Weight (KG):

-

3500

-

Power (kW):

-

15

-

Model:

-

GH-4Z350F

-

Grinding wheel linear speed:

-

30m/s(white corundum wheel)

-

Blade surface can grind per min:

-

2~3

-

Max stroke of main shaft:

-

150mm

-

Actual grinding length:

-

380mm

-

Swift angle:

-

+40°~ -30°

-

Grinding wheel disc size:

-

355x275x125mm

-

Power(W):

-

15KW

-

Control:

-

Huazhong system

-

Application:

-

Knife and sicssor

Quick Details

-

Wheel Size(mm):

-

Barrel wheel 355x275x125mm

-

Year:

-

Latest

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GUOHAO MACHINE

-

Voltage:

-

380V 50HZ 3-PHASE

-

Dimension(L*W*H):

-

2100x1800x1800mm

-

Weight (KG):

-

3500

-

Power (kW):

-

15

-

Model:

-

GH-4Z350F

-

Grinding wheel linear speed:

-

30m/s(white corundum wheel)

-

Blade surface can grind per min:

-

2~3

-

Max stroke of main shaft:

-

150mm

-

Actual grinding length:

-

380mm

-

Swift angle:

-

+40°~ -30°

-

Grinding wheel disc size:

-

355x275x125mm

-

Power(W):

-

15KW

-

Control:

-

Huazhong system

-

Application:

-

Knife and sicssor

The R position grind by 4-axis CNC knife grinding machine can better than the 3-axis machine.

|

Product name

|

4-Axis CNC Single-side Grinder

|

|

|

Model no.

|

GH-4Z350F

|

|

|

Motor power

|

15KW 50HZ 380V 3-PHASE (changable)

|

|

|

Actual grinding length

|

380mm

|

|

|

Main shaft box Max. travel (C-axis)

|

150mm

|

|

|

Valid travel of grinding shaft(Z-axis)

|

30mm

|

|

|

Grinding wheel linear speed

|

30m/s(white corundum wheel)

|

|

|

Swift angle (A-axis)

|

+40° ~-30°

|

|

|

Grinding wheel specification

|

barrel wheel Ф355×Ф275×125mm

|

|

|

Any technical information not refer in the table

please feel free to consult us yingjuan2017@163.com

|

3200kg

|

|

The machine is design to equip a robot arm as automation version, equip with a specialized grinding axis to feed the blades to grind. Use linear guide rail, machine works more stable and will not occurs grinding trace on the blade surface, ensures the stability of machine rigidity. Improve grinding velocity. Equip grinding wheel automatic compensation function.

Adopts 4-axis Huazhong CNC control system, programs can generated by system with valid DXF graph file upload or input manually through the panel. Enable align control of grinding wheel axis fix quantify amount compensation, knife hanger horizontal feeding/vertical grinding, knife rest plate swift angle/feed velocity and feed amount and feed velocity of X, Z, A and C-axis. Multiple operation modes included, Jog, Increment, Electronic hand-wheel, Automatic grinding, Automatic compensation for grinding wheel and more functions.

With correct parameter setting to the system, precision error caused by the gap of ball screw can be reduced or eliminated, quality stability and uniformity of mass production can be ensure.

GH-3Z450 3-axis CNC Knife Single-side Grinding Machine

Enable to grind Single-sided grinding, cutting edge, flat Grinding, polishing, grinding bevel, back edge and other processes of

Ceramic knives, all kinds of ordinary scissors, tailor shears, chef knives / kitchen knives / choppers, triple steel knives, fruit knives, steel knives, hunting knives, daggers, Damascus, etc.

The surface of the produced product is smooth with clear and stable lines.

GH-1000B CNC Vertical Rotary Table Knife Grinding Machine

The machine mainly used for

surface grinding of hardware products, such as scissors and knives.

High efficiency one-time grinding and excellent finished surface quality of the products can meet high quality product

requirement.

GH-4Z450F 4-axis CNC Knife Single-side Grinding Machine

Enable to grind Single-sided grinding, cutting edge, flat Grinding, polishing, grinding bevel, back edge and other processes of Ceramic knives, all kinds of ordinary scissors, tailor shears, chef knives / kitchen knives / choppers, triple steel knives, fruit knives, steel knives, hunting knives, daggers, Damascus, etc. The surface of the produced product is smooth with clear and stable lines.

GH-400B CNC Vertical Rotary Table Knife Grinding Machine

Mainly used for surface grinding of circular-disk kind of products (such as motorcycle brake discs, food machinery circular blades and etc.)

High efficiency one-time grinding and good surface quality of finished products, can meet the quality requirements of client’s high-quality product processing.

Plywood case(optional)

The plywood case steel framework packaging ensure the product prevent from crash, abrasion or damage during shipping. It is a customize case depends on the machine size. Fumigation process will be done before delivery,

and international fumigation sign will mark on the case surface.

*The plywood case requires to pay in additional.

Plastic film(default)

The default simplify packing can prevent steam from entering the machine.

Truck loading

Ocean Carriage

PRE-SALES SUPPORT

Inquiry and consult

Sample testing

Visit our company and factory

AFTER-SALES SUPPORT

Training - how to install and how to use the machine

Online Support

TEL.: (0086 0662) 6601950

WECHAT: +86 186 6623 9592

EMAIL: yingjuan2017@163.com

AVAILABLE: 8:30a.m. to 6:00p.m. from MON to SAT