- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SFC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

4350X1850X1785

-

Year:

-

2024

-

Power (kW):

-

37

-

Weight (KG):

-

5000 KG

-

Model:

-

XK-400

-

Front Roller Linear Speed:

-

18.65

-

Function:

-

1:1.27

-

Rollers material:

-

Chilled Cast Iron

-

Bearing:

-

Easy-disassembly, self-aligning roller bearings

-

Bearing Lubrication:

-

Dry Oil Lubrication System

-

Reducer:

-

Hardened Reducer

Quick Details

-

Diameter of Roll(mm):

-

400 mm

-

Length of Roll(mm):

-

1000 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SFC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

4350X1850X1785

-

Year:

-

2024

-

Power (kW):

-

37

-

Weight (KG):

-

5000 KG

-

Model:

-

XK-400

-

Front Roller Linear Speed:

-

18.65

-

Function:

-

1:1.27

-

Rollers material:

-

Chilled Cast Iron

-

Bearing:

-

Easy-disassembly, self-aligning roller bearings

-

Bearing Lubrication:

-

Dry Oil Lubrication System

-

Reducer:

-

Hardened Reducer

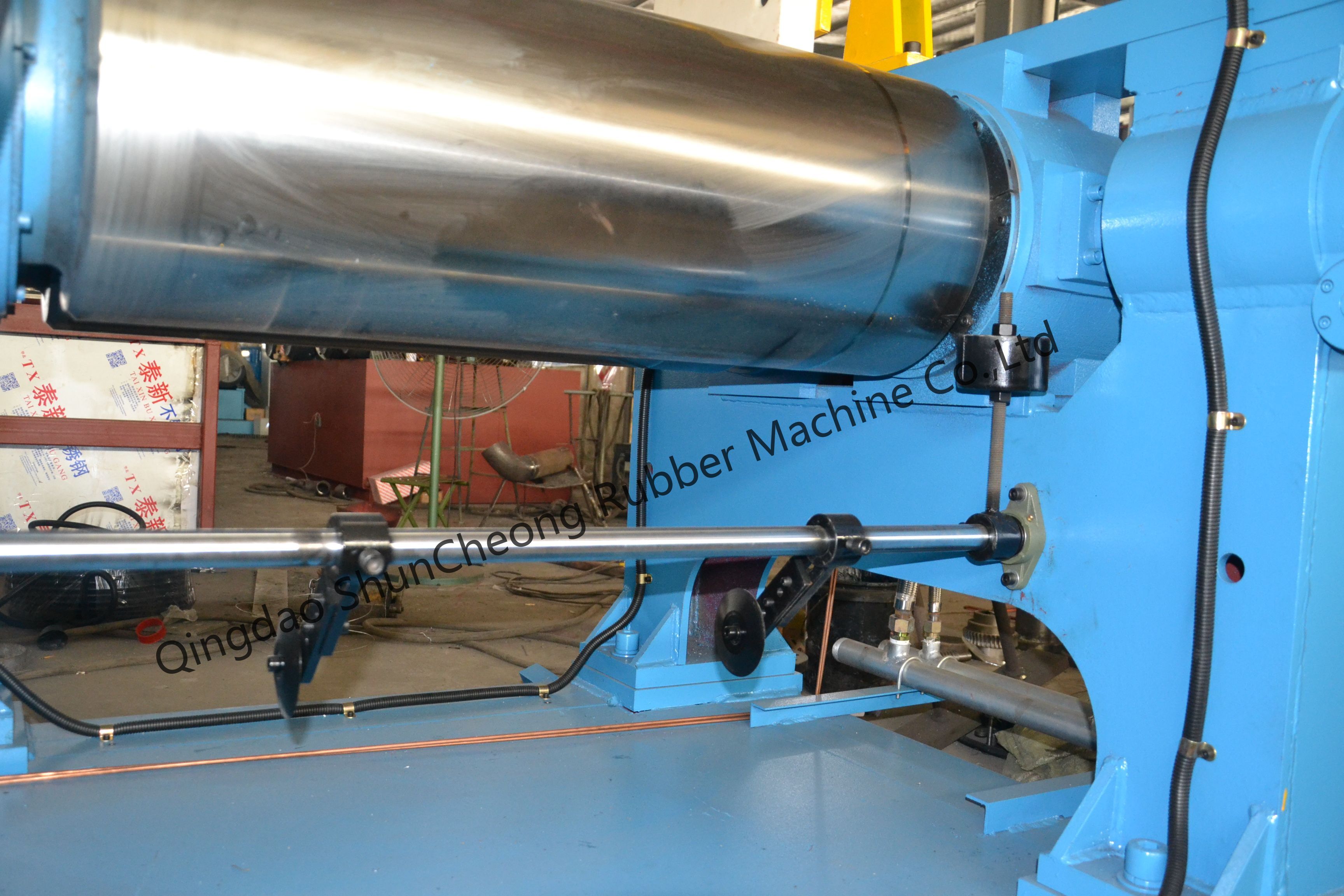

Products Description

Equipment

Application

This rubber compound two roll mill is mainly used in Rubber & Plastic Product factory for Natural RubberMixing(plasticating), Raw Rubber and Compound mixing, rubber warm-up mixing and pressing sheet.

Product Feature

1. Machine frame, gland and base are all welded through steel plates, after annealing, completely processed by precise machine tool. The whole machine frame, gland and base are all of strong rigidity, won't deform and the surface is smooth and anti-wear.

2. The 2 ends of the rolls adopt double roller rolling aligning bearings. Bearings adopt automatic thin oil lubrication system.Roll Bearings adopt automatic thin oil lubrication style.

3. Rollers cooling water adopt copper rotary joints. Rollers are made of chilled cast iron, front and rear rollers are hollow type, so as to achieve better temperature control effect, the working surface hardness is 68 ~ 72HSD.

2. The 2 ends of the rolls adopt double roller rolling aligning bearings. Bearings adopt automatic thin oil lubrication system.Roll Bearings adopt automatic thin oil lubrication style.

3. Rollers cooling water adopt copper rotary joints. Rollers are made of chilled cast iron, front and rear rollers are hollow type, so as to achieve better temperature control effect, the working surface hardness is 68 ~ 72HSD.

4. Reducer adopts square ZSYF355 hard tooth gear reducer, 6 grade precision, very low noise, long service life.

5. Roller bearings: High precision self-aligning roller bearings.

6. Emergency Brake Equipment: In front and rear of the machine are equipped with 4 emergency stopping buttons and also in the mill base is equipped a Kick-style stop switch.

7. Equipment safety devices. To protect the machine main parts from damage, the machine is connected with safety pads protection device. When the machine is overloaded, the safety disc will rupture protecting the main parts of the equipment from damage.

Product Paramenters

|

Model

|

Roller(DxL)(mm)

|

Front Roller

Linear Speed(m/min) |

Friction Ratio

|

Motor Power

(KW) |

Overall Dimension (LxWxH)(mm)

|

|

XK-150

|

φ150x320

|

8.38

|

1:1.21

|

5.5

|

1500x750x1500

|

|

XK-230

|

φ230x600

|

10.21

|

1:1.19

|

15

|

2800x1200x1120

|

|

XK-250

|

φ250x620

|

14.1

|

1:1.17

|

18.5

|

3400x1500x1650

|

|

XK-300

|

φ300x750

|

15.1

|

1:1.25

|

22

|

3500x1600x1700

|

|

XK-360

|

φ360x900

|

16.25

|

1:1.25

|

30

|

3780x1850x1750

|

|

XK-400

|

φ400x1000

|

18.65

|

1:1.27

|

37

|

4350x1850x1785

|

|

XK-450

|

φ450x1200

|

24.26

|

1:1.27

|

55

|

5200x2380x1840

|

|

XK-560

|

φ560xφ510x1530

|

27.72

|

1:1.2

|

90

|

5845x2284x1978

|

|

XK-550B

|

φ550x1500

|

27.94

|

1:1.22

|

110

|

5870x2475x2045

|

|

XK-610

|

φ610x2000

|

28.42

|

1:1.17

|

160

|

7070x2290x1840

|

|

XK-660

|

φ660x2130

|

28.6

|

1:1.24

|

245

|

7465x3662x2080

|

Product packaging

Equipment painting completed before delivery, and then wrapped with stretch film, avoid rubbing the paint off the surface, wooden packaging can be customized, key parts, such as electronic control box, will be wrapped by shockproof packaging materials, and

then packed in wooden cases.

then packed in wooden cases.

FAQ

1. What does your factory do regarding quality control?

We pay much more importance to quality control from the very beginning to the end of production. Every machine will be fully assembled and carefully tested before shipment.

2. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand components to keep our machine in perfect working condition.

3. Are you able to give installation and commissioning overseas?How long time will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation. Small machine usually takes within 2~3 days. Big production line usually takes about 30 days.

4. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is

innovation,quality,integrity and efficiency. Also we have had many good cooperation with world famous rubber production

manufacturers.If you come to our factory, we can show the user around us.

5. How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name of airport is Qingdao Jiaodong airport. We will pick up you at

the airport.

Before leaving factory, this plate vulcanizing press needs to pass 24 hours' pressure test, pressure maintaining to test the

bearing of the hydro-cylinder and piston stroke and guarantee no oil leakage and seeping to avoid unnecessary quality problems.

We pay much more importance to quality control from the very beginning to the end of production. Every machine will be fully assembled and carefully tested before shipment.

2. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand components to keep our machine in perfect working condition.

3. Are you able to give installation and commissioning overseas?How long time will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation. Small machine usually takes within 2~3 days. Big production line usually takes about 30 days.

4. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is

innovation,quality,integrity and efficiency. Also we have had many good cooperation with world famous rubber production

manufacturers.If you come to our factory, we can show the user around us.

5. How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name of airport is Qingdao Jiaodong airport. We will pick up you at

the airport.

Before leaving factory, this plate vulcanizing press needs to pass 24 hours' pressure test, pressure maintaining to test the

bearing of the hydro-cylinder and piston stroke and guarantee no oil leakage and seeping to avoid unnecessary quality problems.

Our Services And Certifications

♦ Our engineers can design target machines for customers and send them the drawing to confirm. We are always on the side of saving your cost.

♦ In the process of production, we will take photos and send to customers for their track the progress.

♦ Documents such as packing list, commercial invoice, and bill of lading etc. will be sent after the delivery.

♦ We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing.

♦ We supply overseas engineer service and help to train your workers to operate the machine.

♦ In the process of production, we will take photos and send to customers for their track the progress.

♦ Documents such as packing list, commercial invoice, and bill of lading etc. will be sent after the delivery.

♦ We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing.

♦ We supply overseas engineer service and help to train your workers to operate the machine.

Hot Searches