Black aluminium oxide is also known as low aluminum corundum. It is also a new type product of polishing material, and it is a dark gray crystal body made Al2O3 and ferropicotite as main ore in the electric arc furnace by smelting the bauxite. It has characteristics of moderate hardness, high toughness, high temperature resistance, and stable thermal stability.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Xinli

-

Model Number:

-

Black fused alumina

-

Usage:

-

Polishing

-

Al2O3:

-

85%

-

TiO2:

-

2-4%

-

Fe2O3:

-

6-9%

-

SiO2:

-

5-8%

-

Abrasive Grain:

-

F8-F3000

-

Sample:

-

free

-

Certification:

-

ISO9001

-

MOQ:

-

1MT

-

Application:

-

Abrasive Refractory Industry

-

Product name:

-

black fused alumina

Quick Details

-

Type:

-

abrasive

-

Abrasive Grain Sizes:

-

F8-F3000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xinli

-

Model Number:

-

Black fused alumina

-

Usage:

-

Polishing

-

Al2O3:

-

85%

-

TiO2:

-

2-4%

-

Fe2O3:

-

6-9%

-

SiO2:

-

5-8%

-

Abrasive Grain:

-

F8-F3000

-

Sample:

-

free

-

Certification:

-

ISO9001

-

MOQ:

-

1MT

-

Application:

-

Abrasive Refractory Industry

-

Product name:

-

black fused alumina

Product Description

Introduction of black fused alumina:

Main functions of black fused alumina:

(1) as there is high temperature, corrosion resistance, high strength properties, it poured with steel sliding gate, smelting rare metals, special alloys, ceramics, iron-smelting furnace of the lining (walls and tubes); physical and chemical containers , spark plugs, heat-resistant anti-oxidation coating.

(2) due to high hardness, wear resistance, high strength characteristics, in the chemical system, used for a variety of reaction vessels and pipelines, chemical pump parts; to do mechanical parts, various molds, such as the Roberts mold, extrusion die nozzle pencil lead, etc.; do tool, die grinding, bullet-proof material, the human body joints, sealing ring mold.

(3) corundum insulating materials, such as lightweight corundum brick, corundum hollow ball and fiber products, widely used in a variety of high-temperature kiln furnace walls and roof, both high-temperature insulation again.

(2) due to high hardness, wear resistance, high strength characteristics, in the chemical system, used for a variety of reaction vessels and pipelines, chemical pump parts; to do mechanical parts, various molds, such as the Roberts mold, extrusion die nozzle pencil lead, etc.; do tool, die grinding, bullet-proof material, the human body joints, sealing ring mold.

(3) corundum insulating materials, such as lightweight corundum brick, corundum hollow ball and fiber products, widely used in a variety of high-temperature kiln furnace walls and roof, both high-temperature insulation again.

|

Product name

|

Black aluminium oxide abrasive

|

|

|

|

|

||||

|

Chemical (%)

|

Grit Size

|

Al2O3

|

Fe2O3

|

SiO2

|

TiO2

|

||||

|

|

10#-220#

|

>78.00

|

>5.0

|

>9.00

|

1.5-3.5

|

||||

|

|

240#-1000#

|

>66.00

|

>5.0

|

>10.0

|

1.5-3.0

|

||||

|

Advantage

|

High toughness,

High temperature resistance,

Stable thermal property,

Strong cutting ability,

Durability,

High work efficiency.

|

|

|

|

|

||||

|

Parameter

|

The color: black

The shape: particle in trigonal shape

Melt point:2050°C

The max temperature:1850°C

True density(g/cm3): ≥3.50

Coefficient of linear expansion(0-1600°C): 7-9 |

|

|

|

|

||||

|

Usage

|

1.It is used for the bicycle, motorcycle, sewing machine, and clock parts.

2.Light ornament, plastic and hardware polishing, and also applicable to the sand blasting.

3.It is the production materials: manufacturing resin-cutting slice, edges and corners grinding and coated abrasives.

4.Black corundum particle and micro powder are suitable for stainless steel work piece polishing and abrading and making the whetstone and polishing paste.

5.Black corundum powder is the preferred material of the slip-prevented road and coal pits warehousing

|

|

|

|

|

||||

|

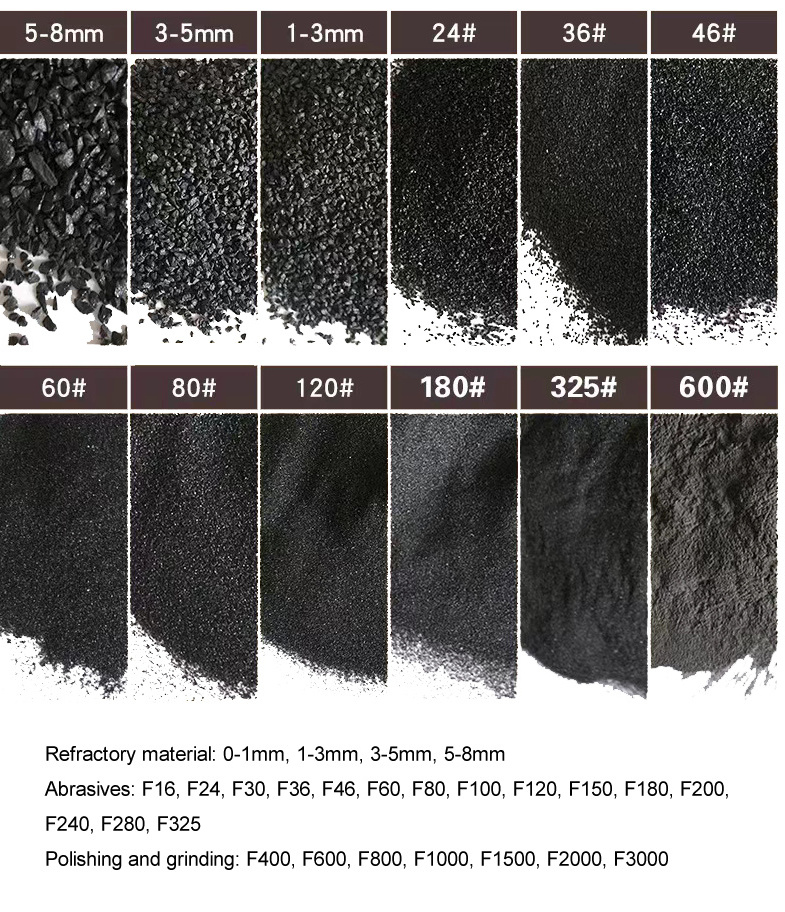

Available sizes

|

JIS

|

#8 #10 #12 #14 #16 #20 #24 #30 #36 #46 #54 #60 #70 #80 #90 #100 #120 #150 #180 #220 #240 #280 #320 #360 #400 #500 #600 #800 #1000

#1200 #1500 |

|

|

|

||||

|

|

FEPA

|

F8 F10 F12 F14 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 F230 F240 F280 F320 F360 F400 F500

F600 F800 F1000 |

|

|

|

||||

Black aluminium oxide abrasive advantages

1.Choosing selected bauxite and iron oxide as raw material be smelted in tilting electrical arc furnace

2.Strong cutting force

3.Moderate hardness but good toughness and self-sharpening

4.Good abrasion resistance

5.Less heat value and efficient productivity

6.High temperature resistance

2.Strong cutting force

3.Moderate hardness but good toughness and self-sharpening

4.Good abrasion resistance

5.Less heat value and efficient productivity

6.High temperature resistance

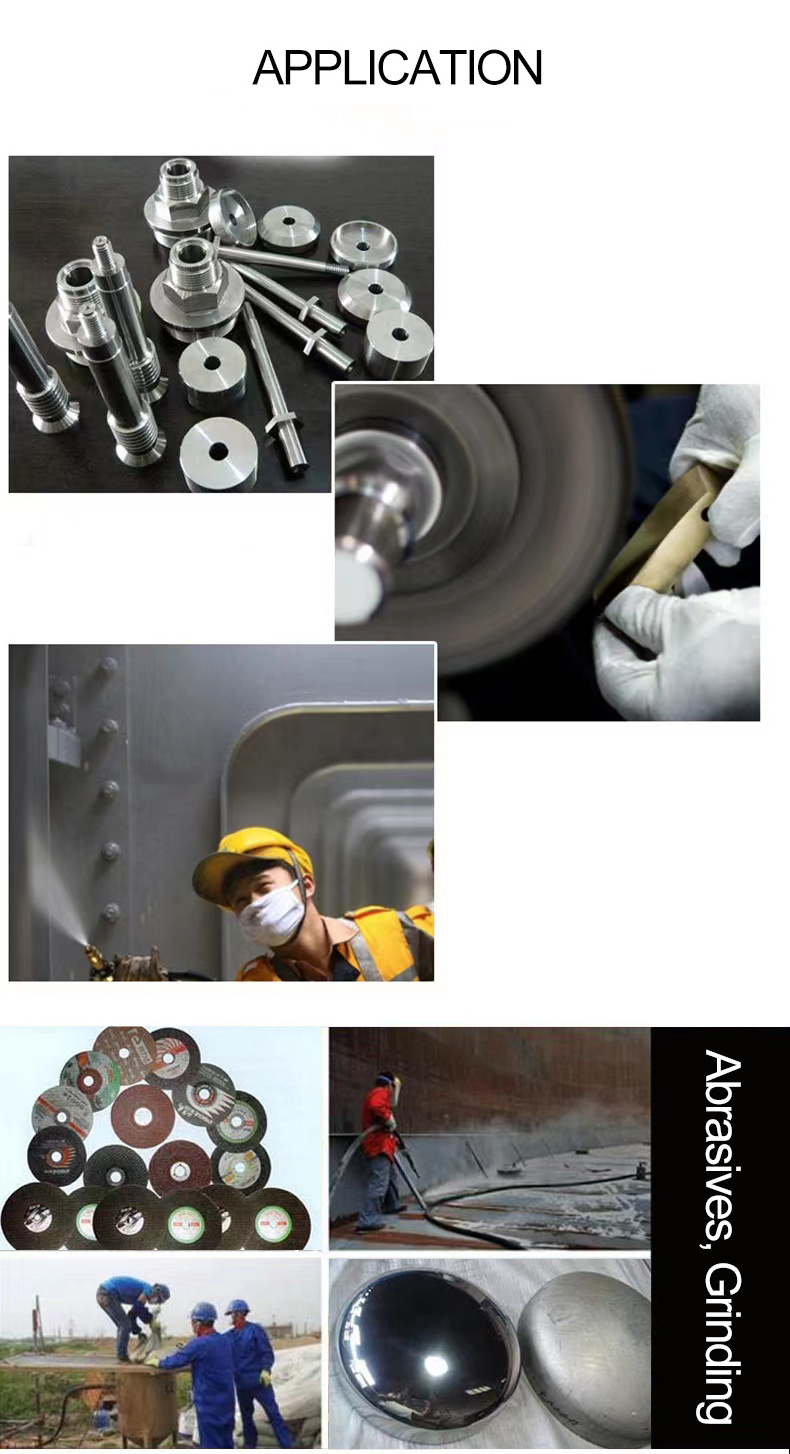

Application

Our Black aluminium oxide abrasive application

For abrasives, grinding of electronics, metallurgical additive.

For special ceramics, foam ceramics

For auto parts, war industry and aviation, steel making

For abrasive and cutting tools and Cutting disks made of SiC

For grinding, honing, water-jet cutting and sandblasting.

For lapping and polishing ,metallurgical additive and refractory material.

For abrasives, grinding of electronics, metallurgical additive.

For special ceramics, foam ceramics

For auto parts, war industry and aviation, steel making

For abrasive and cutting tools and Cutting disks made of SiC

For grinding, honing, water-jet cutting and sandblasting.

For lapping and polishing ,metallurgical additive and refractory material.

Hot Products

Packing & Delivery

White fused alumina, white corundum powder, white fused alumina powder, white corundum, aluminum oxide

※ 1ton/jumbo bag

※ Jumbo bag + Wooden pallets

※ 25kgs/bag, 40 bags/jumbo bag

※ 25kgs/woven bag or kraft paper bag

※ All package can be customized according to customers' requirements

※ 25kgs/bag, 40 bags/jumbo bag

※ 25kgs/woven bag or kraft paper bag

※ All package can be customized according to customers' requirements

Hot Searches